Customer Success Story

Divi’s Labs relies on 100% network uptime for pharmaceutical quality control

Divi’s Labs makes the active ingredients in antidepressants, blood pressure medicines, antihistamines, and dozens of other drugs. Its nutraceutical division makes vitamins and beta-carotenes used in supplements, food, and beverages. Divi’s manufacturing facilities in India are the largest in the world.

Divi’s relies on Juniper networking to support research and development, manufacturing, and quality control.

100%

Network uptime required for quality control

14,000

Square-meter pharma manufacturing capacity is largest in the world

0

Network-related issues in 8 years

16,500

Employees

Connecting the world’s largest pharma manufacturing sites

“Quality is at the heart of our business,” says Manoranjan Jasti, Chief Information Officer at Divi’s Labs. “Manufacturing operations run 24/7, and interruptions to network services during the production of a batch cannot be tolerated. If a single network packet drops, the quality-control process will fail and the entire batch must be discarded.”

Delivering ultra-reliable network services to meet Divi’s quality standards and compliance requirements is challenging due to the sheer size of the manufacturing facilities. Its plant in Hyderabad spans 4000 square meters, while its facility near Visakhapatnam is 10,000 square meters. Together, they cover more than 64 production buildings.

Divi’s needed a network that could securely transfer data at line rate between its two plants without any packet loss to maintain its quality controls.

Not a single packet can be lost

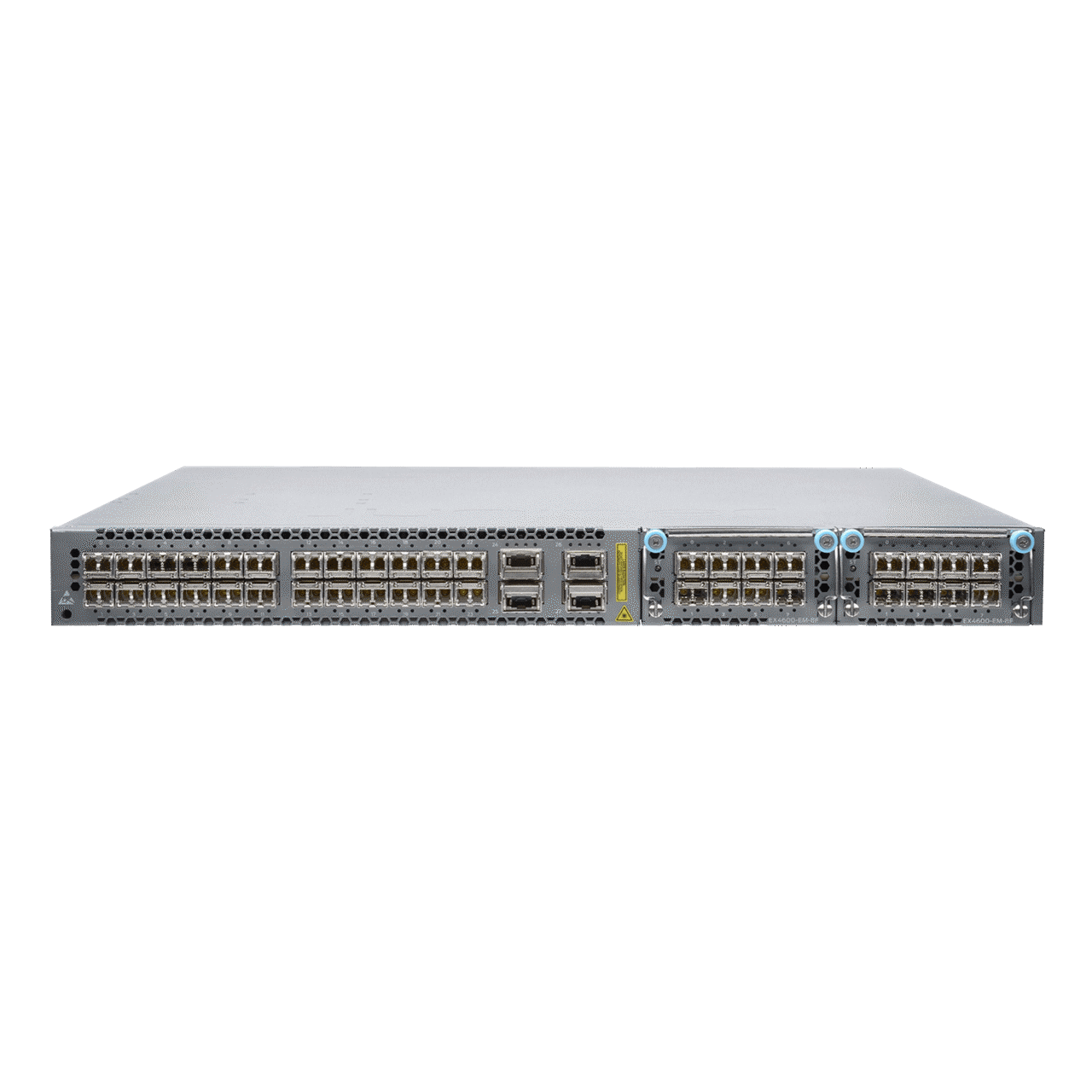

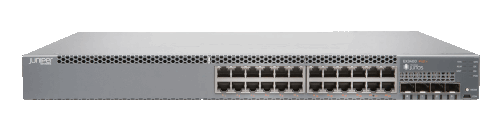

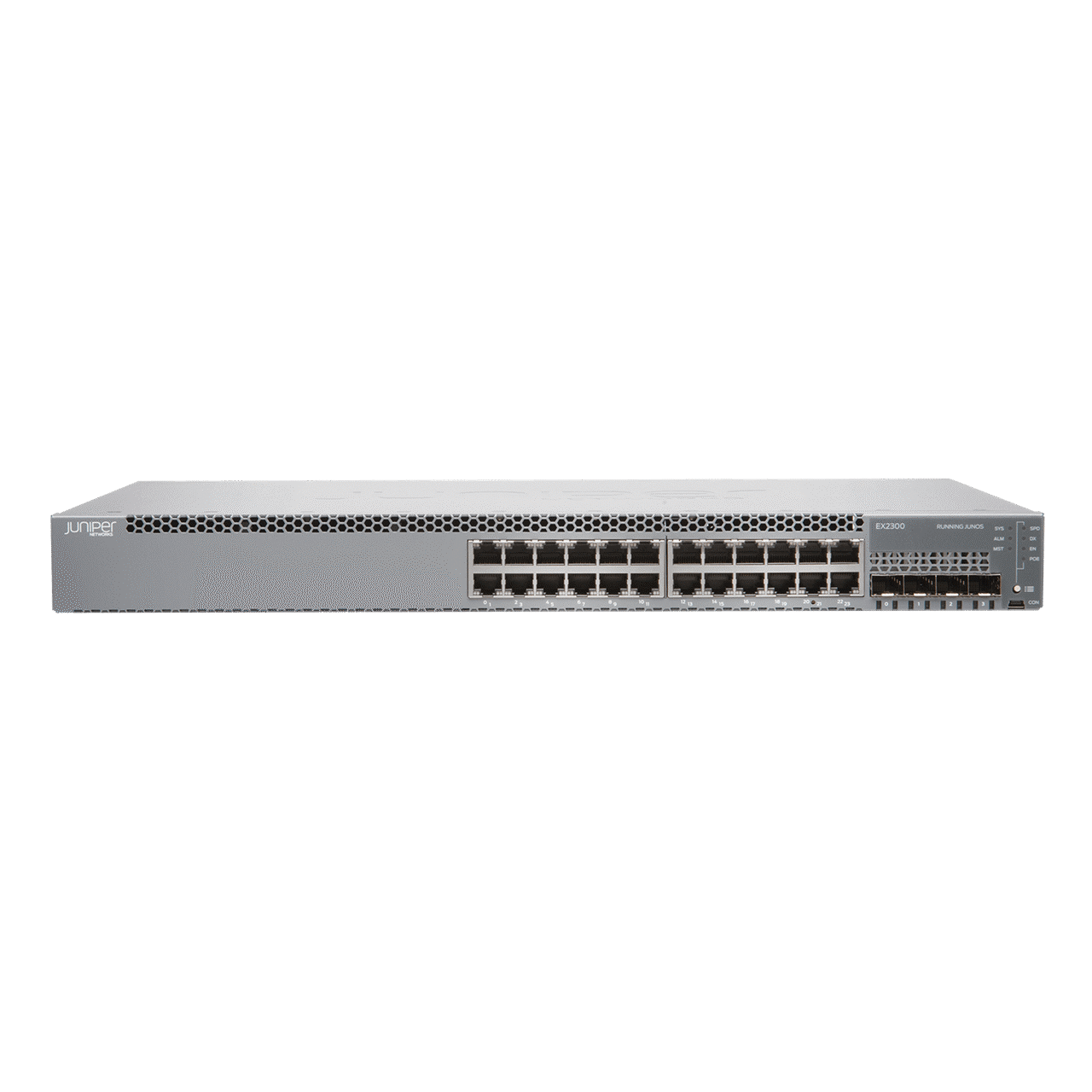

Divi’s relies on Juniper EX Series Switches to deliver highly available, ultra-reliable networking for its manufacturing operations and quality control processes.

Juniper EX4600 switches are used for the core and distribution networks. The EX4600 switch, with wire-speed 10-Gbps and 40-Gbps ports, delivers up to 1.2 Tbps of connectivity in a compact platform. In the plants, Juniper EX3400 and EX2300 switches connect the production blocks and power wireless access points. A production block may span 2.5 kilometers.

In the data center, Juniper switches support critical manufacturing processes, including formula management, batch tracking, quality control, compliance tracking, and production scheduling.

MACsec encryption provides point-to-point security. With Juniper Virtual Chassis technology, IT can configure, manage, and upgrade multiple EX switches as if they were a single device for simplicity and speed.

“With Juniper, we can scale and manage switches easily for production blocks,” says Jasti.

Zero downtime in eight years supports product quality

“Our Juniper network gives us the reliability and flexibility we need to support research and development, manufacturing, and quality control,” says Jasti. “The network has met the expectations of our end-user departments and it has saved significant money for our company.”

The pandemic has accelerated change across the healthcare industry. With an agile business model, a reputation for quality, and ample manufacturing capacity, Divi’s can enable the steady supply of its products to global pharmaceutical companies to help people gain access to the medications they need and live healthier lives.

Divi’s Laboratories Selects Juniper Networks for Automated Network Infrastructure Across Massive Pharma Manufacturing Facilities

Published January 2023