ON THIS PAGE

Replacing an MX2000 Three-Phase Delta AC Power Distribution Module

Replacing an MX2020 Three-Phase Wye AC Power Distribution Module

Replacing an MX2008 DC Power Distribution Module Cable (-48 V)

Replacing an MX2000 DC Power Distribution Module (240 V China)

Replacing an MX2000 High-Voltage Second-Generation Universal (HVAC/HVDC) Power Supply Module

Replacing an MX2000 High-Voltage Universal (HVAC/HVDC) Power Distribution Module

Maintaining MX2008 Power System Components

Replacing an MX2008 AC Power Supply Module

Removing an MX2008 AC Power Supply Module

Before you remove a PSM, be aware of the following:

To maintain proper cooling and prevent thermal shutdown of the operating PSM, each PSM slot must contain either a PSM or a blank panel. If you remove a PSM, you must install a replacement PSM or a blank panel shortly after the removal.

After powering off a PSM, wait at least 60 seconds before turning it back on.

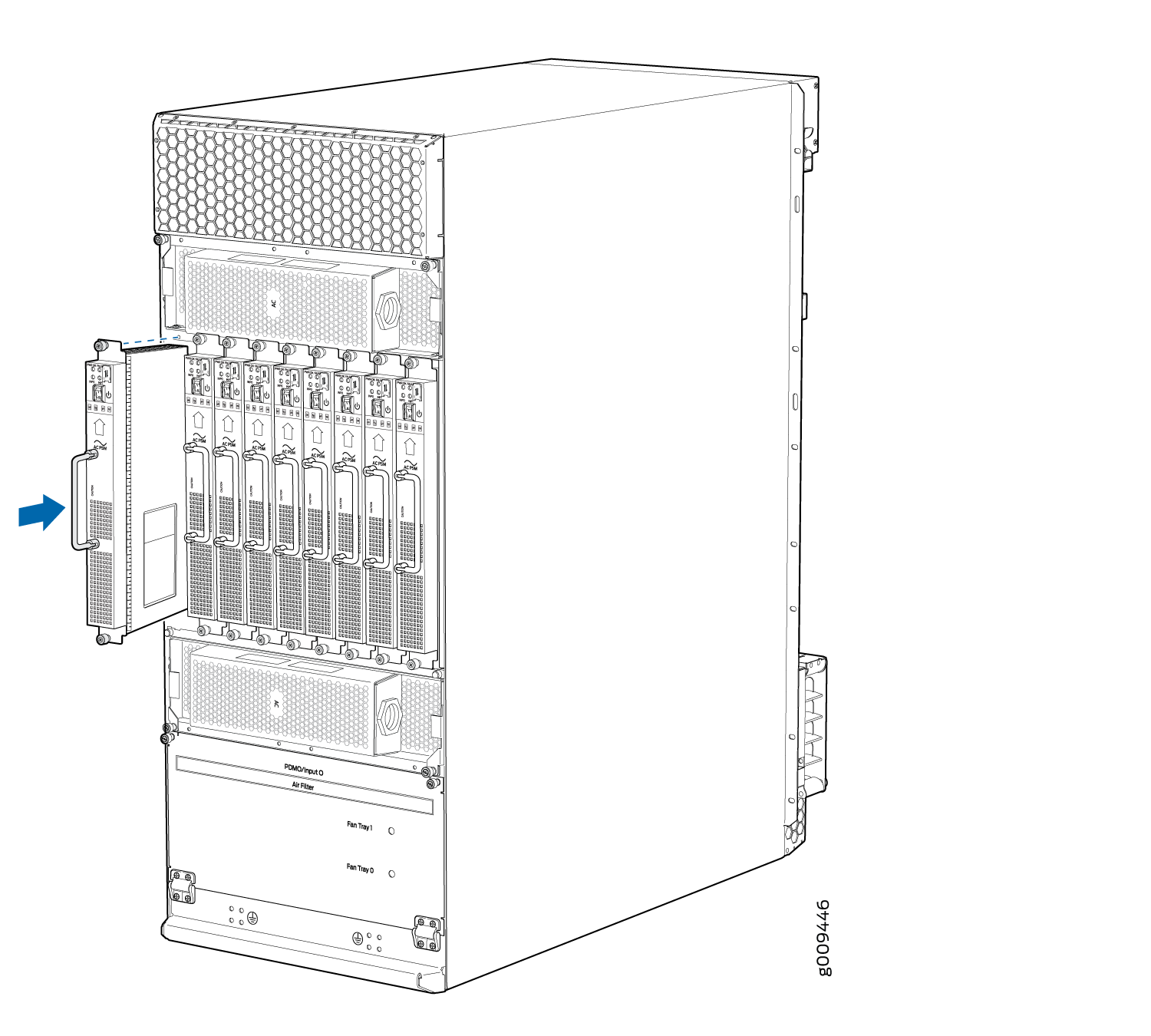

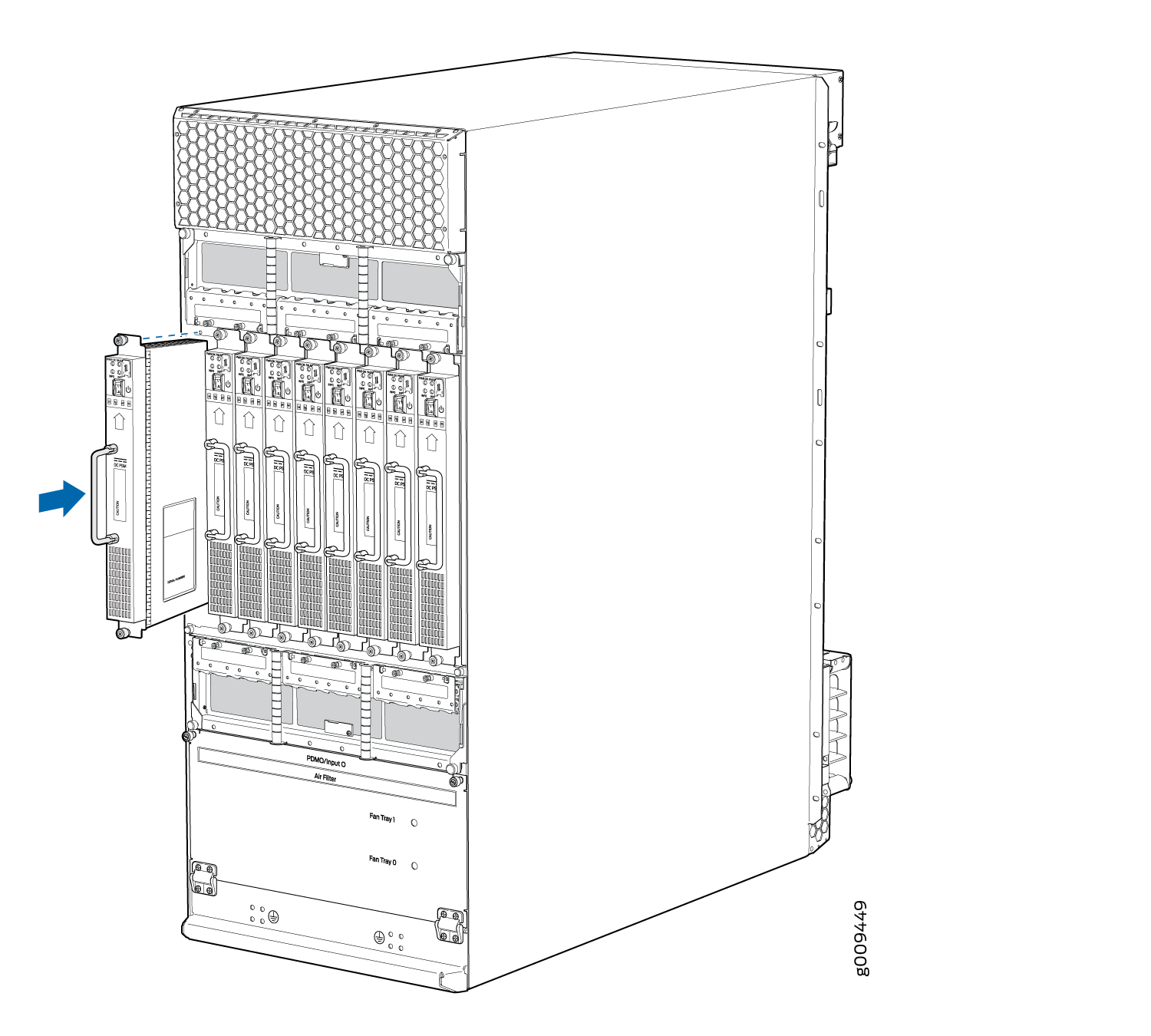

To remove an AC PSM (see Figure 1):

The minimum number of AC PSMs changes based on the configuration.

Installing an MX2008 AC Power Supply Module

Before you install a PSM, be aware of the following:

The AC PSM is hot-swappable when a minimum number of PSMs installed and operational.

The AC PSMs have no circuit breakers that can physically disconnect AC line from the router. After AC feeds have been connected to the PDM, the AC voltage is always present on the power midplane and is distributed to the PSM connectors on the power midplane.

To maintain proper cooling and prevent thermal shutdown of the operating PSM, each PSM slot must contain either a PSM or a blank panel. If you remove a PSM, you must install a replacement PSM or a blank panel shortly after the removal.

After powering on a PSM, wait at least 60 seconds before turning it back off.

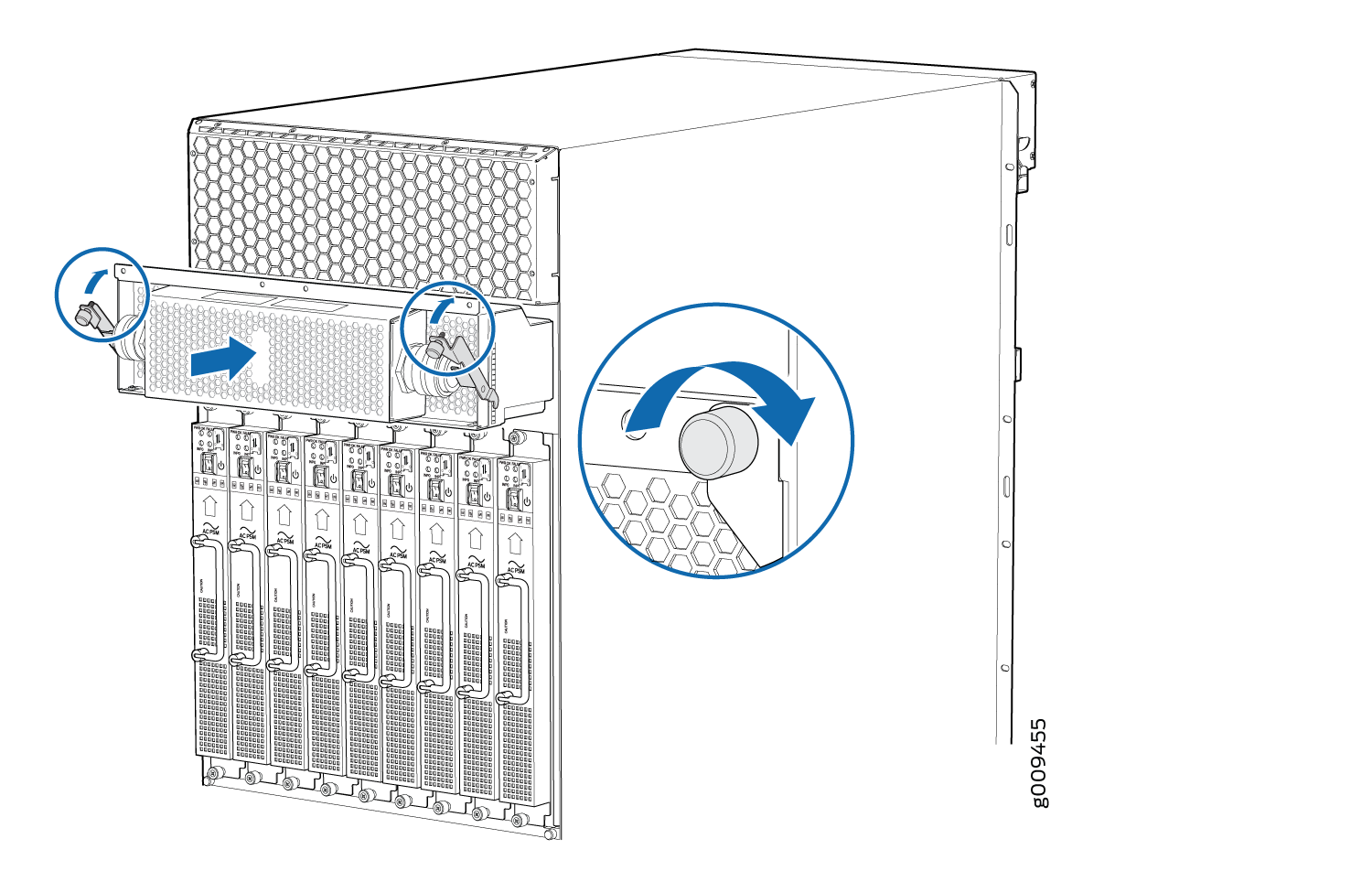

To install an AC PSM (see Figure 2):

Replacing an MX2000 Three-Phase Delta AC Power Distribution Module

- Removing an MX2000 Three-Phase Delta AC Power Distribution Module

- Installing an MX2000 Router Three-Phase Delta AC Power Distribution Module

Removing an MX2000 Three-Phase Delta AC Power Distribution Module

Before you remove a three-phase delta AC PDM, be aware of the following:

Before performing AC power procedures, disconnect all power sources. To ensure that all power is OFF, locate the circuit breaker on the panel board that services the AC circuit, switch the circuit breaker to the OFF position, and tape the switch handle of the circuit breaker in the OFF position.

Do not touch the power connectors on the PDM. They can contain dangerous voltages.

To maintain proper cooling and prevent thermal shutdown of the operating power supply unit, each PDM slot must contain either a PDM or a blank panel. If you remove a PDM, you must install a replacement PDM or a blank panel shortly after the removal.

After powering off a PDM, wait at least 60 seconds before turning the circuit breaker to the ON position.

The MX2008, MX2010, and MX2020 routers support the same power modules (AC/DC PSMs and AC/DC PDMs).

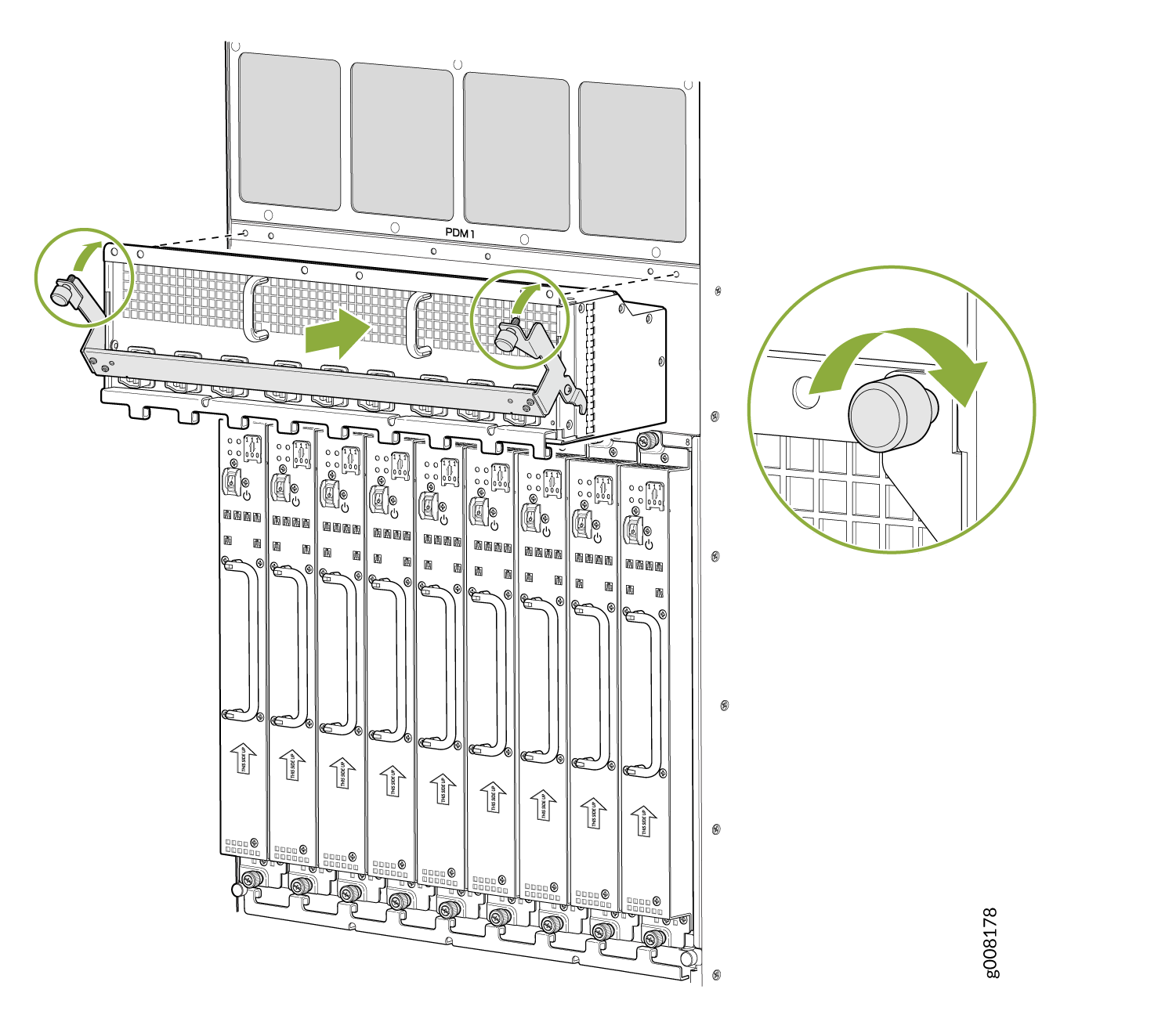

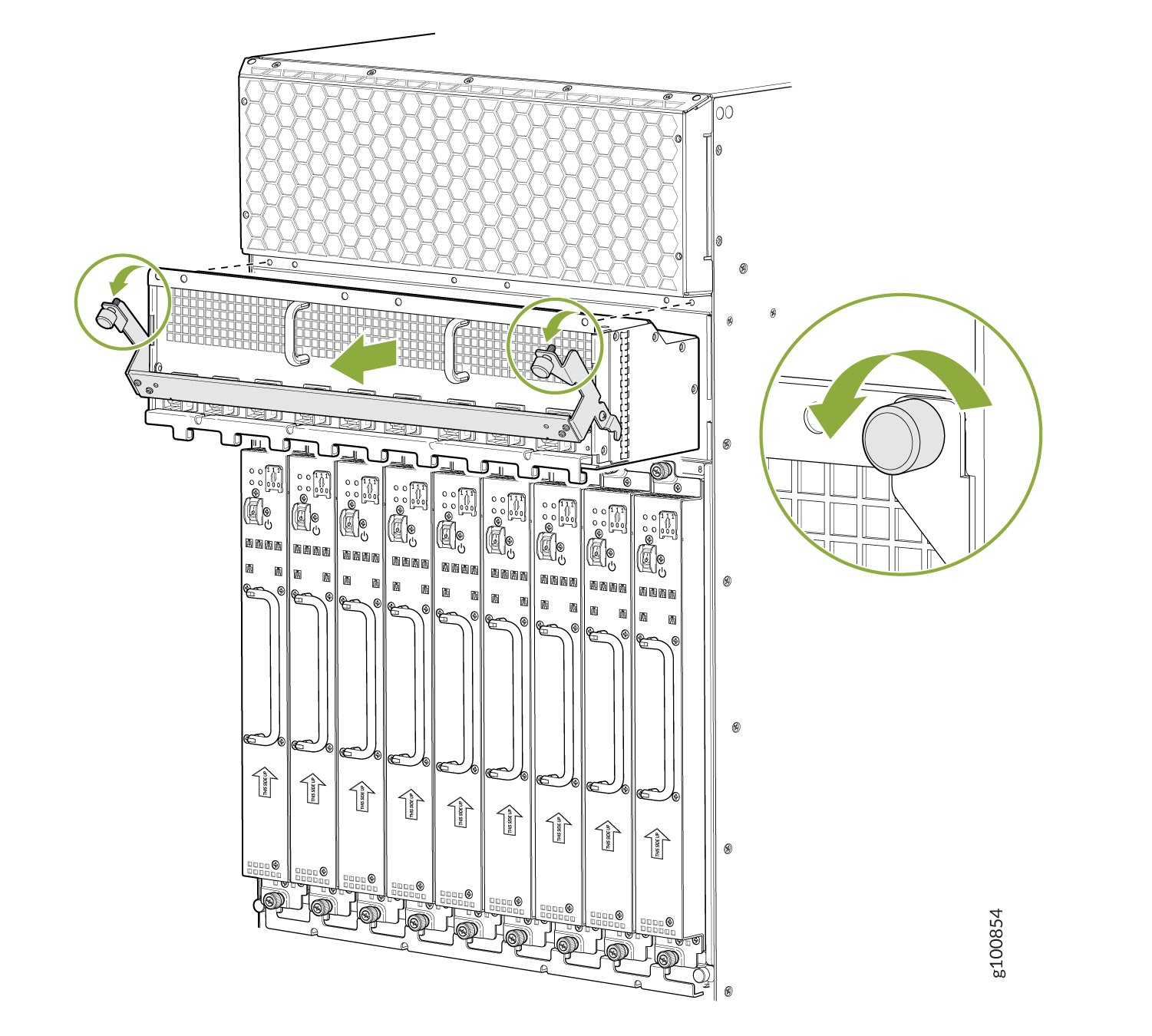

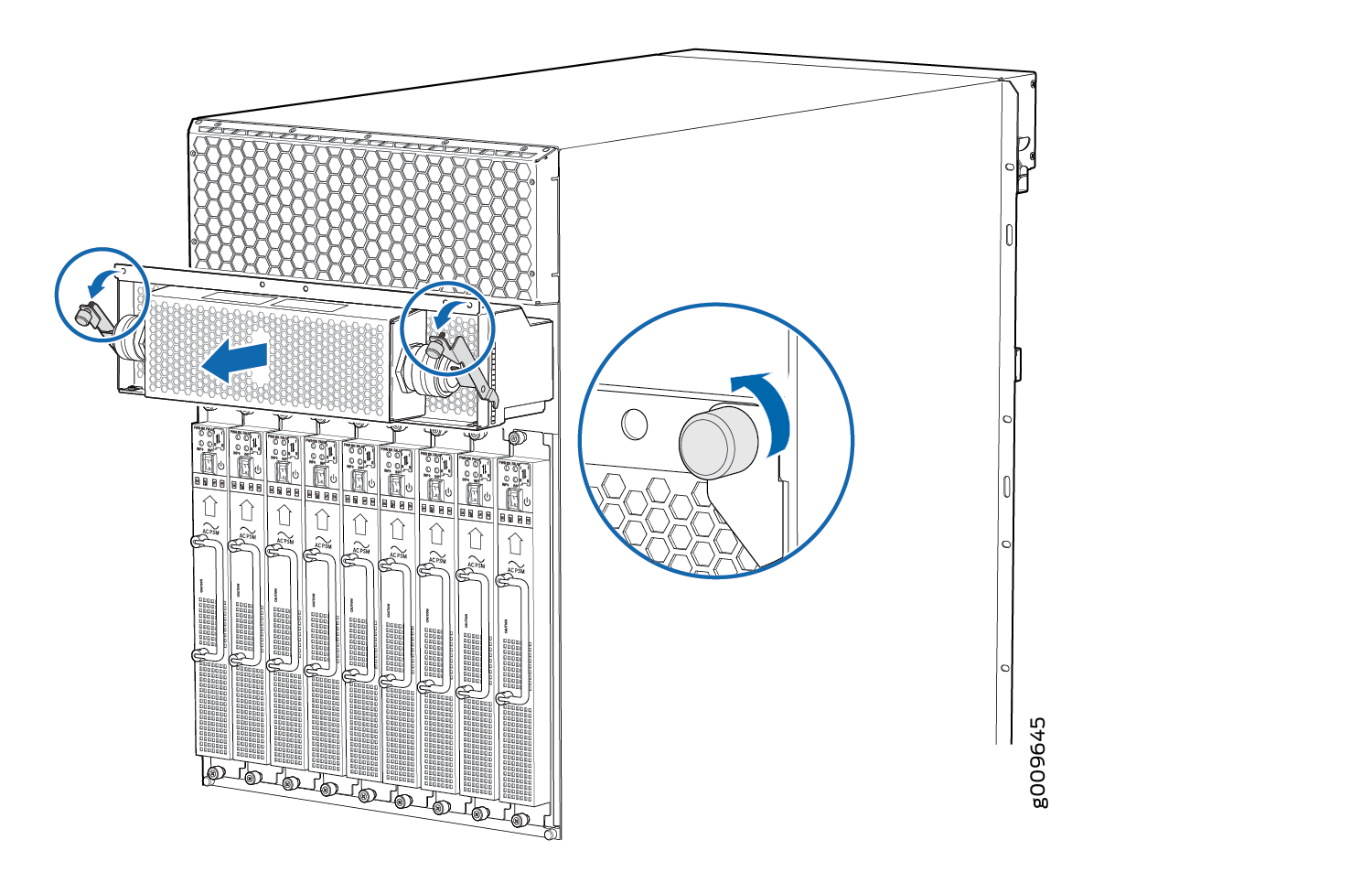

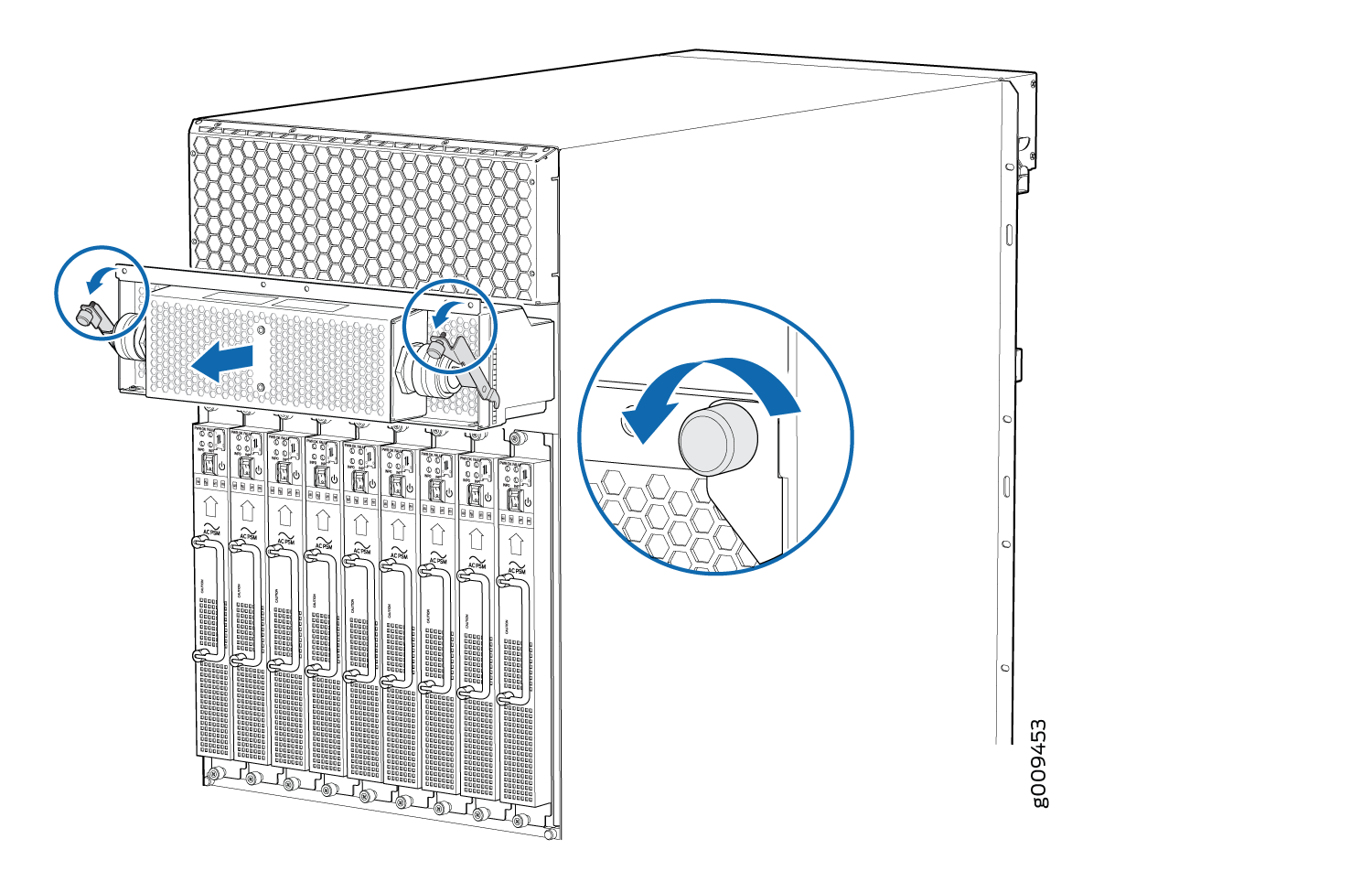

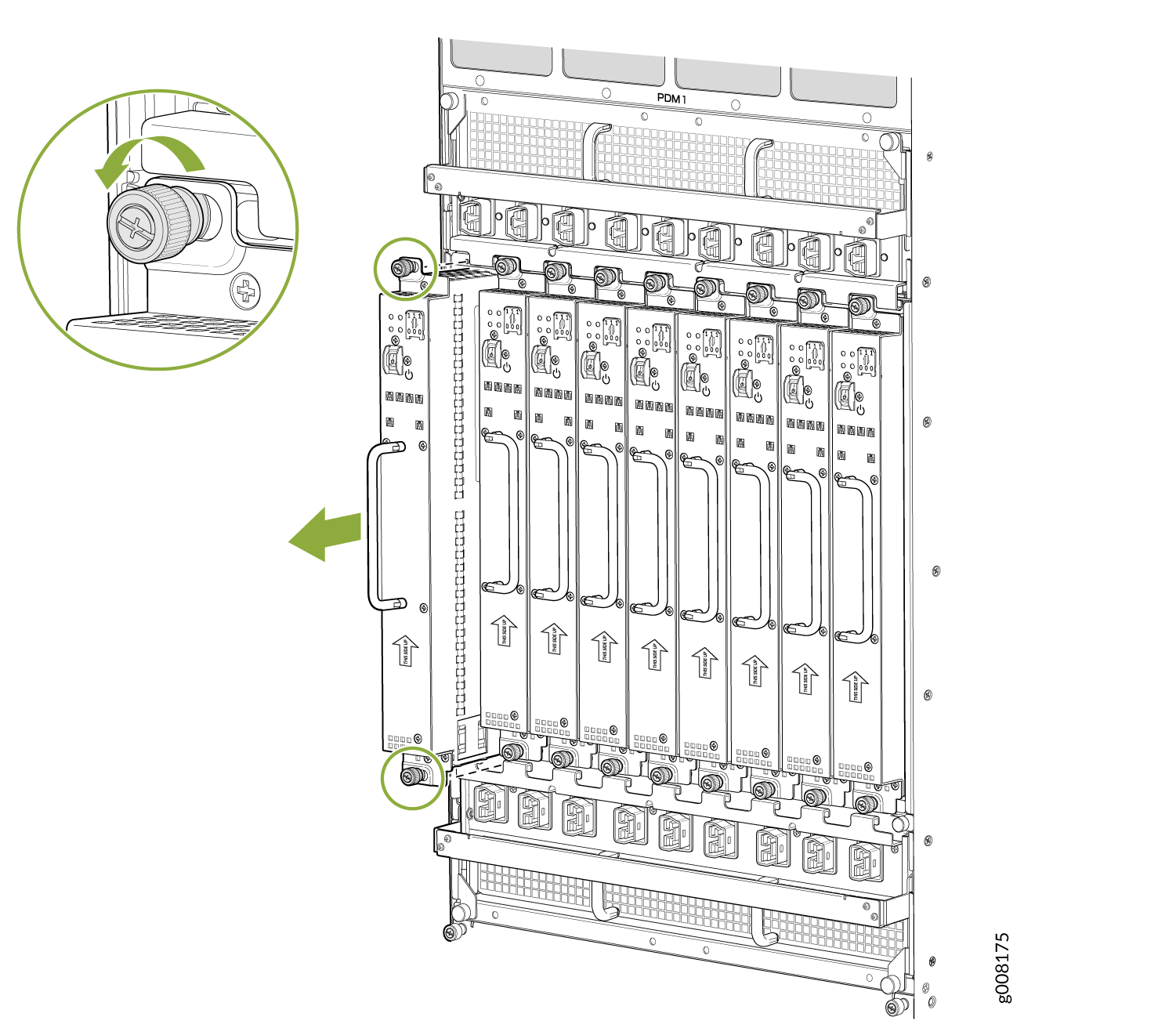

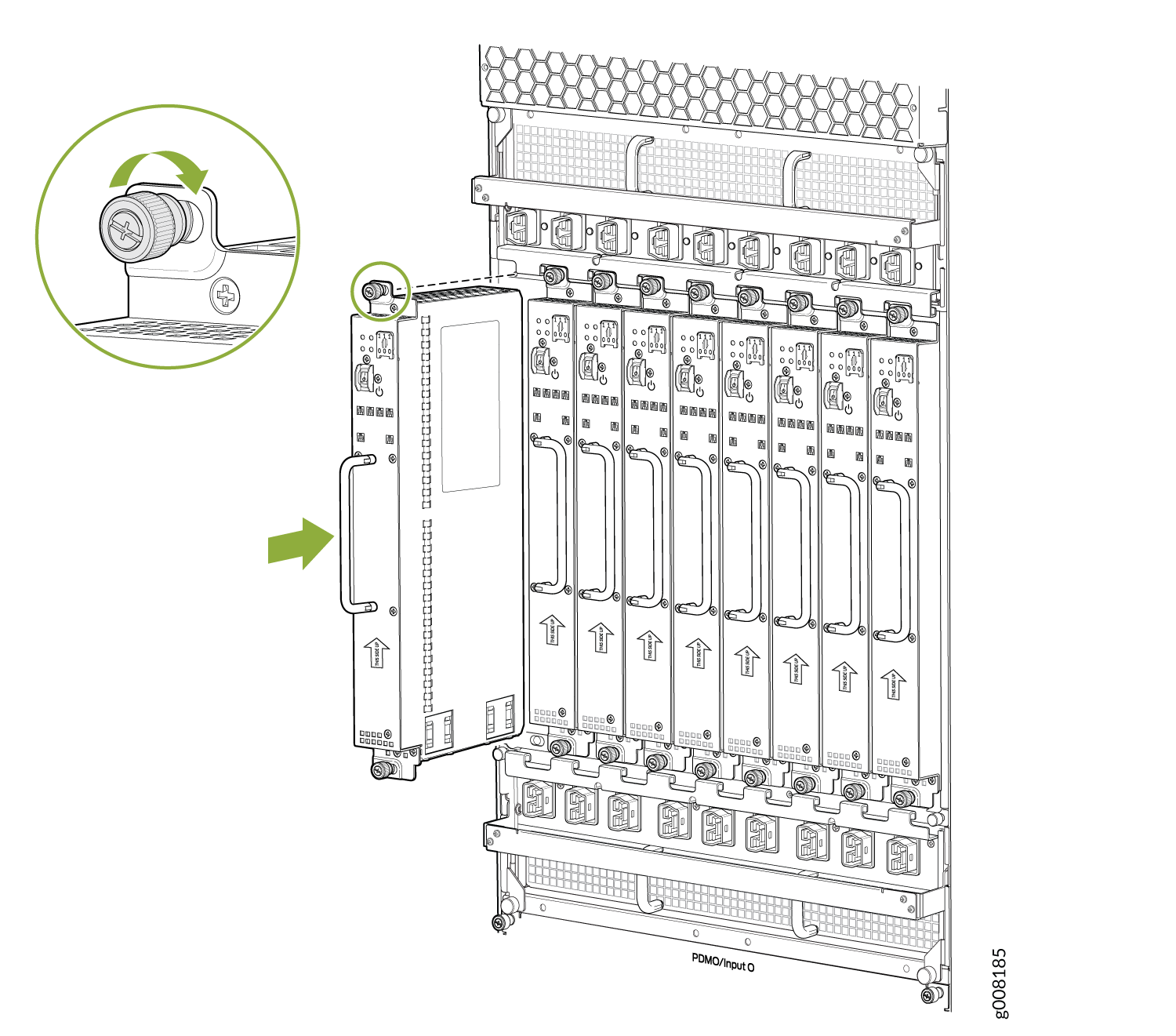

To remove a three-phase delta AC PDM:

Each PDM slot not occupied by a AC PDM must be covered by a PDM blank panel.

See Also

Installing an MX2000 Router Three-Phase Delta AC Power Distribution Module

Before you install a three-phase delta AC power distribution module (PDM), be aware of the following:

Before performing AC power procedures, disconnect all power sources. To ensure that all power is off, locate the circuit breaker on the panel board that services the AC circuit, switch the circuit breaker to the off position, and tape the switch handle of the circuit breaker in the off position.

To maintain proper cooling and prevent thermal shutdown of the operating power supply unit, each PDM slot must contain either a PDM or a blank panel. If you remove a PDM, you must install a replacement PDM or a blank panel shortly after the removal.

After powering off a PDM, wait at least 60 seconds before turning the circuit breaker back on.

The PDMs are hot swappable in a redundant configuration. However, you cannot switch from one type of PDM (AC or DC) to another while the system is on.

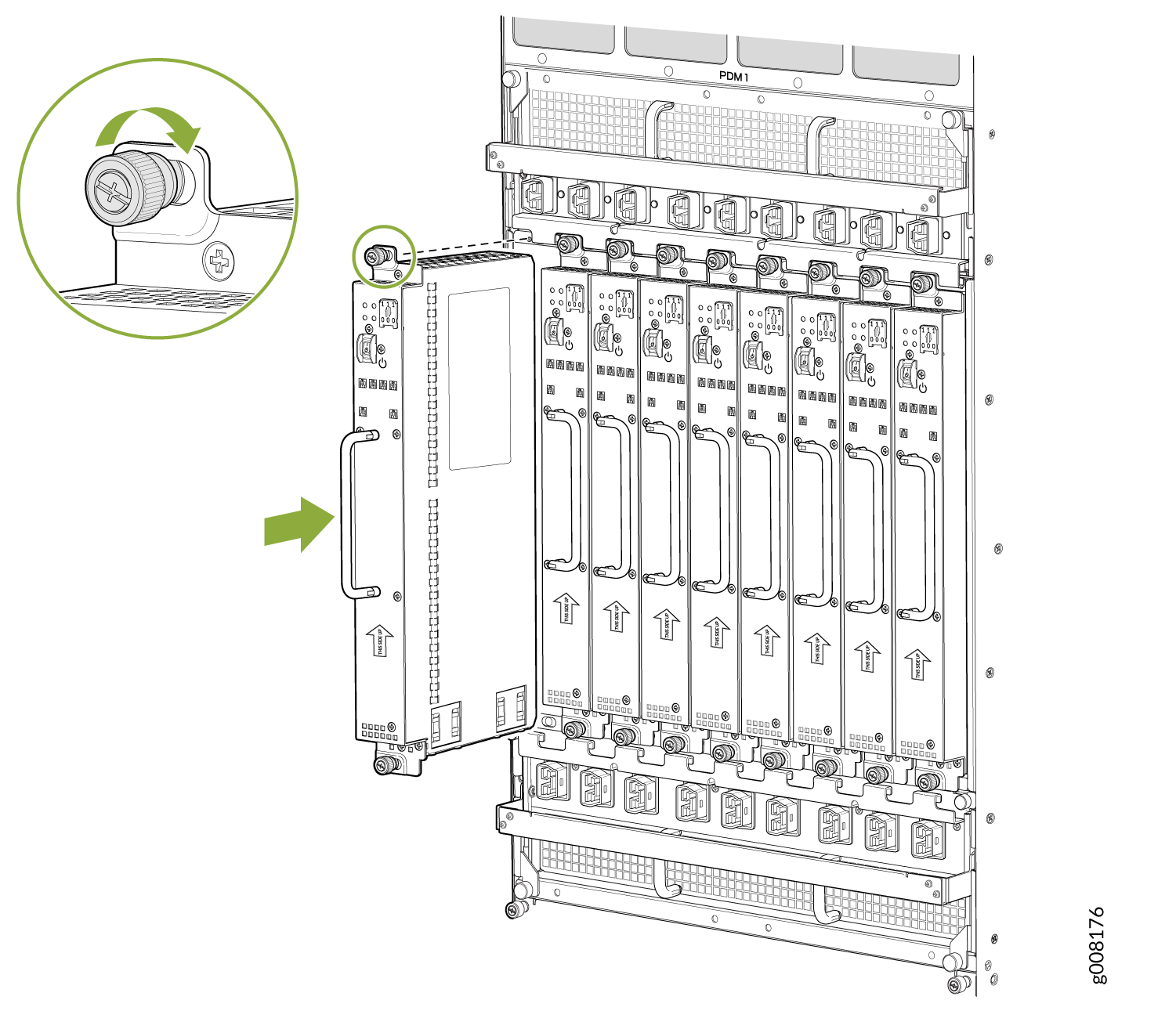

Each three-phase delta AC PDM weighs approximately 12 lb (5.44 kg). To install a three-phase delta AC PDM:

Replacing an MX2008 Three-Phase Delta AC Power Cord

The MX2008 router has either one redundant PDM or two redundant PDMs. An AC power cord on a redundant PDM is hot-insertable and hot-removable. When a redundant PDM is powered down, the other PDM automatically assumes the entire electrical load for the router. If you have only one PDM, you must power off the system before removing the AC power cord.

- Removing an MX2008 Three-Phase Delta AC Power Cord

- Installing an MX2008 Three-Phase Delta AC Power Cord

Removing an MX2008 Three-Phase Delta AC Power Cord

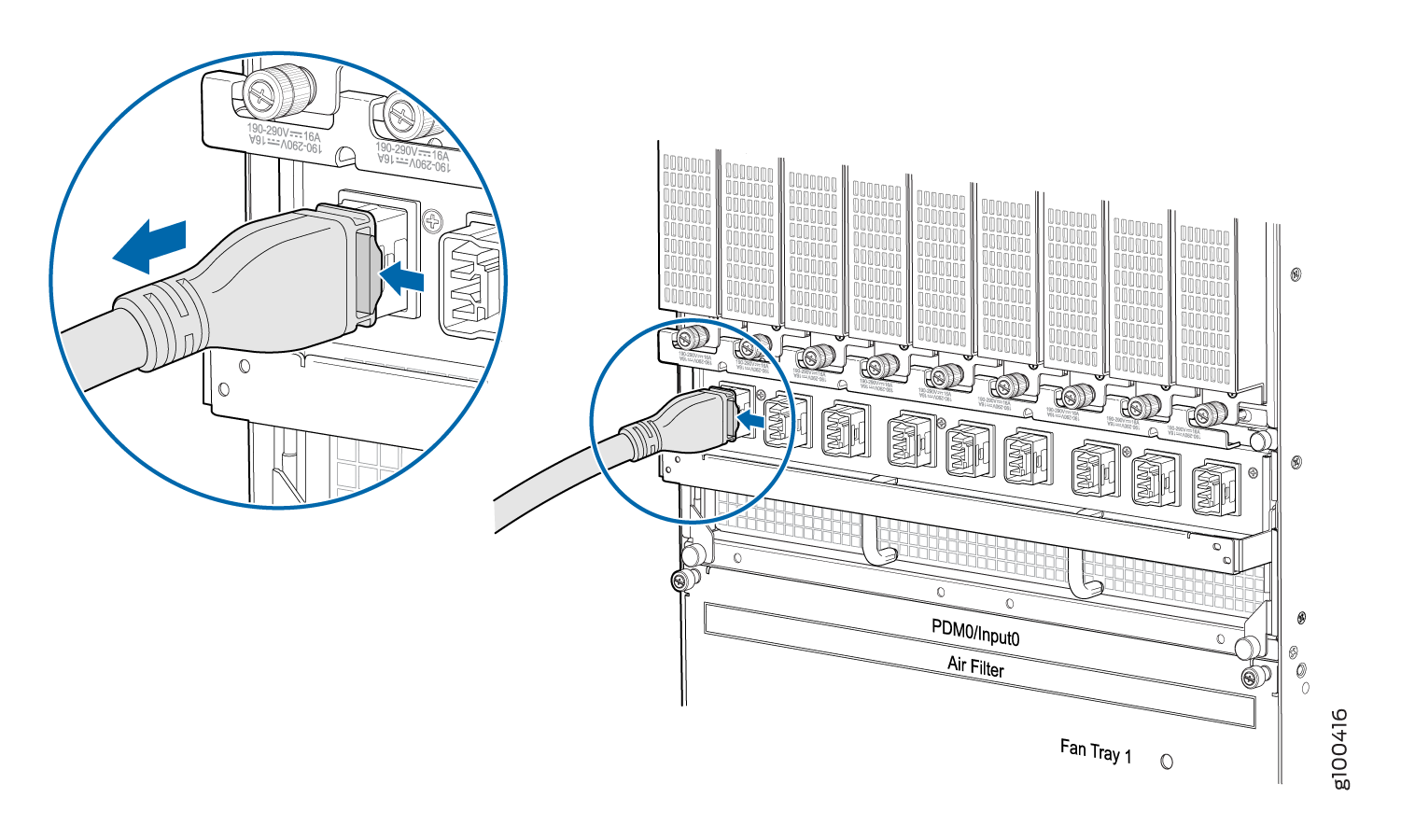

To remove a three-phase delta AC power cord:

Installing an MX2008 Three-Phase Delta AC Power Cord

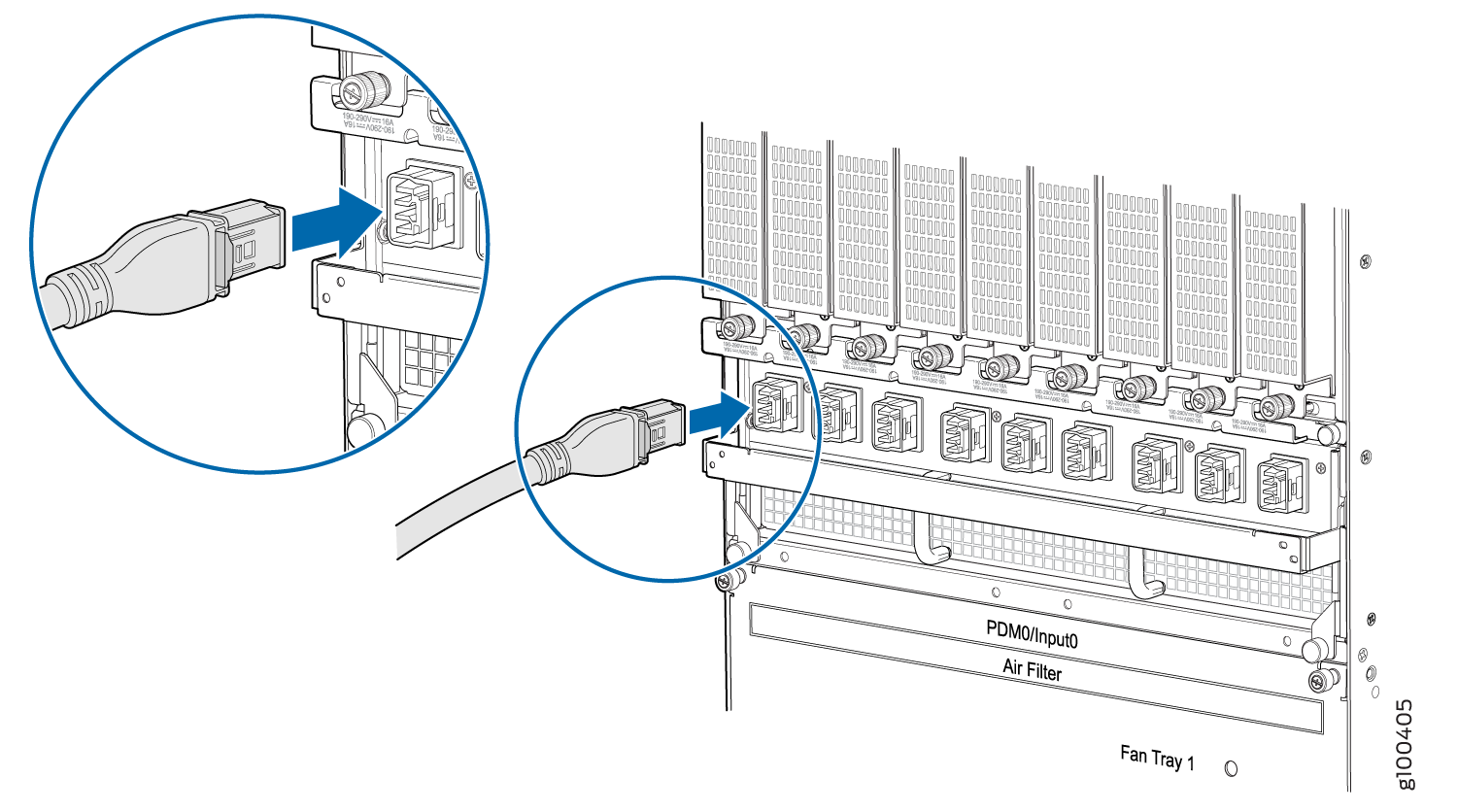

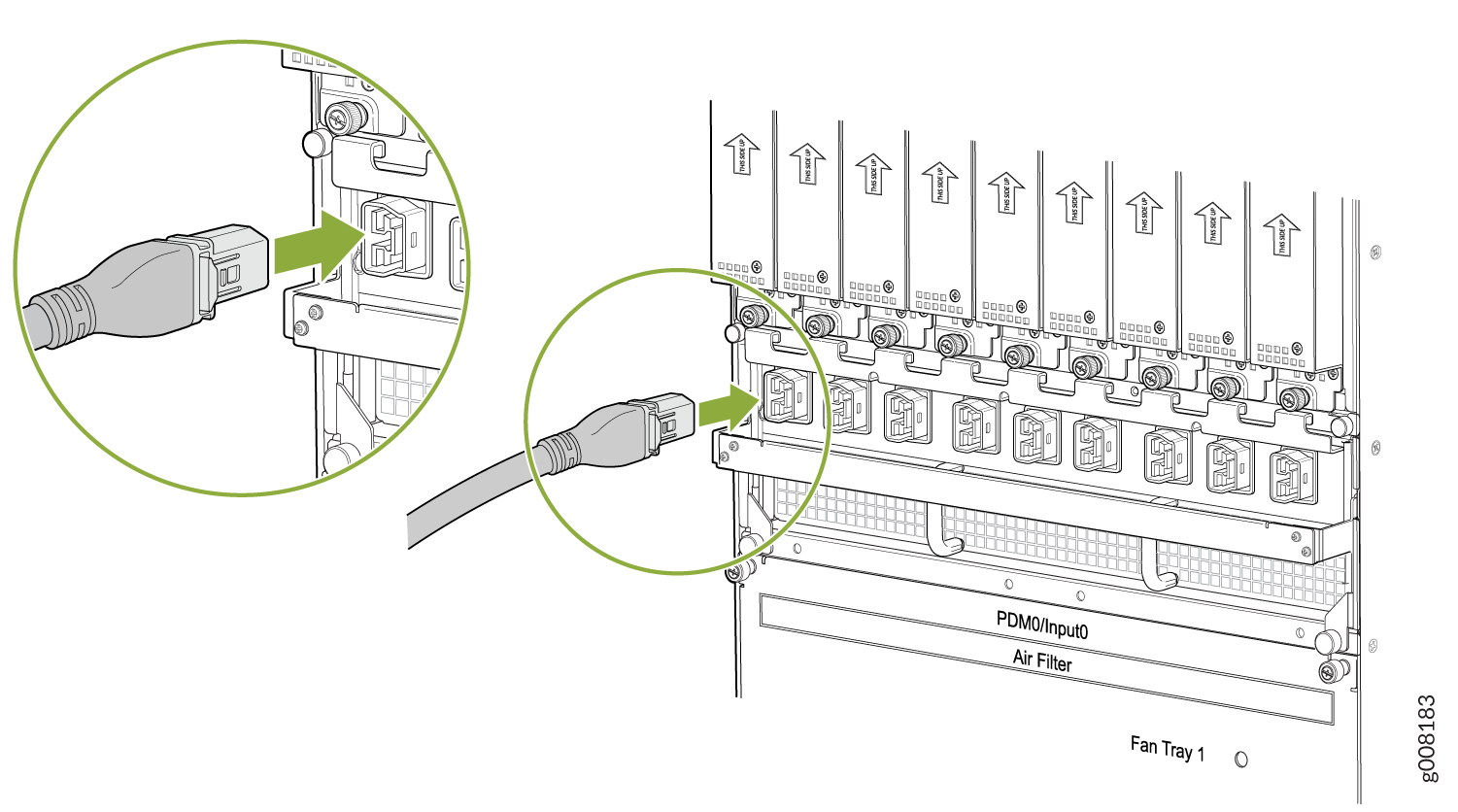

To install a three-phase delta AC power cord:

Replacing an MX2020 Three-Phase Wye AC Power Distribution Module

- Removing an MX2000 Three-Phase Wye AC Power Distribution Module

- Installing an MX2000 Router Three-Phase Wye AC Power Distribution Module

Removing an MX2000 Three-Phase Wye AC Power Distribution Module

Before you remove a three-phase wye AC Power Distribution Module (PDM), be aware of the following:

Before performing AC power procedures, disconnect all power sources. To ensure that all power is off, locate the circuit breaker on the panel board that services the AC circuit, move the circuit breaker to the OFF position, and tape the switch handle of the circuit breaker in the OFF position.

Do not touch the power connectors on the PDM. They can contain dangerous voltages.

To maintain proper cooling and prevent thermal shutdown of the operating power supply unit, each PDM slot must contain either a PDM or a blank panel. If you remove a PDM, you must install a replacement PDM or a blank panel shortly after the removal.

After powering off a PDM, wait at least 60 seconds before turning the circuit breaker back on.

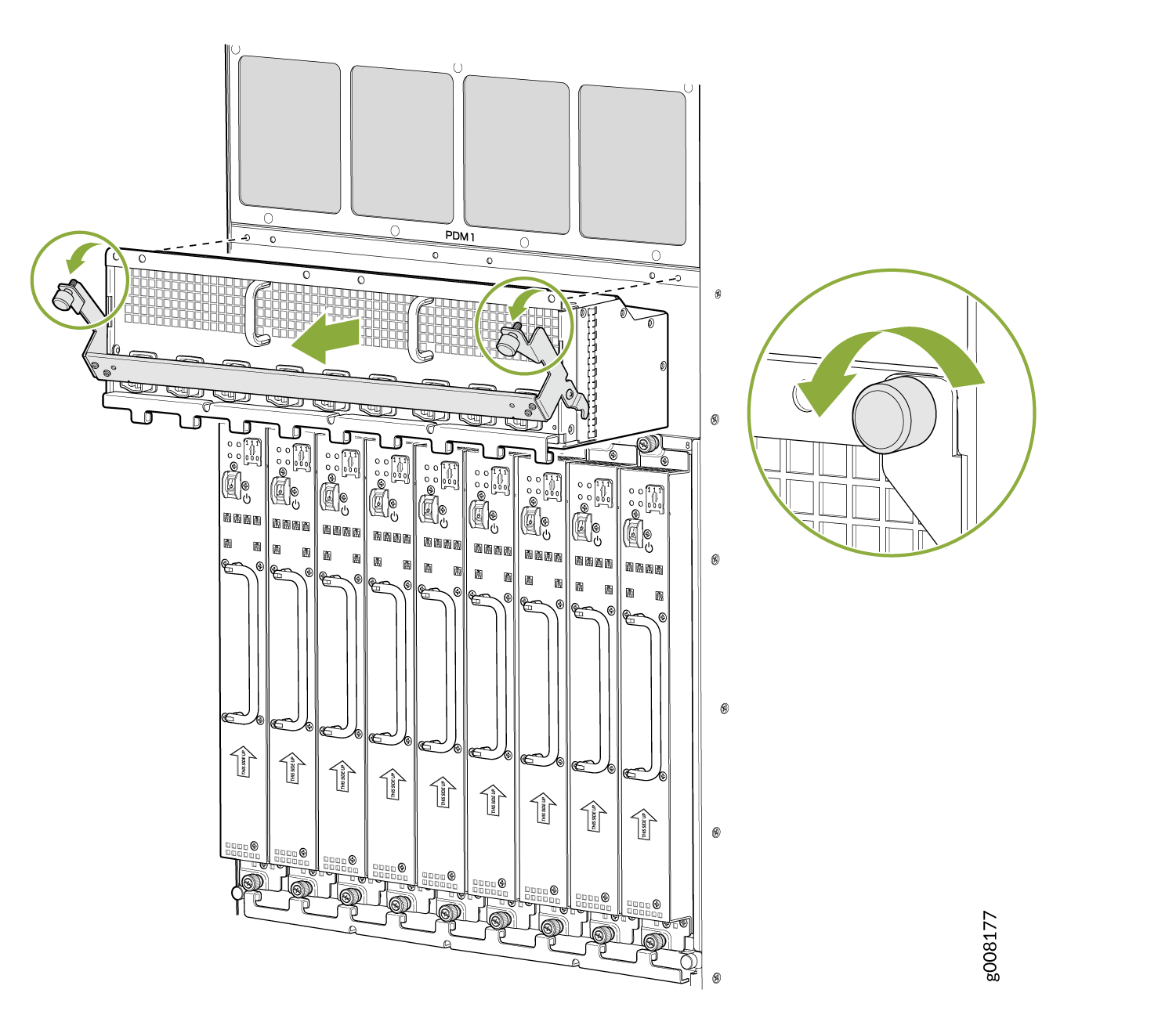

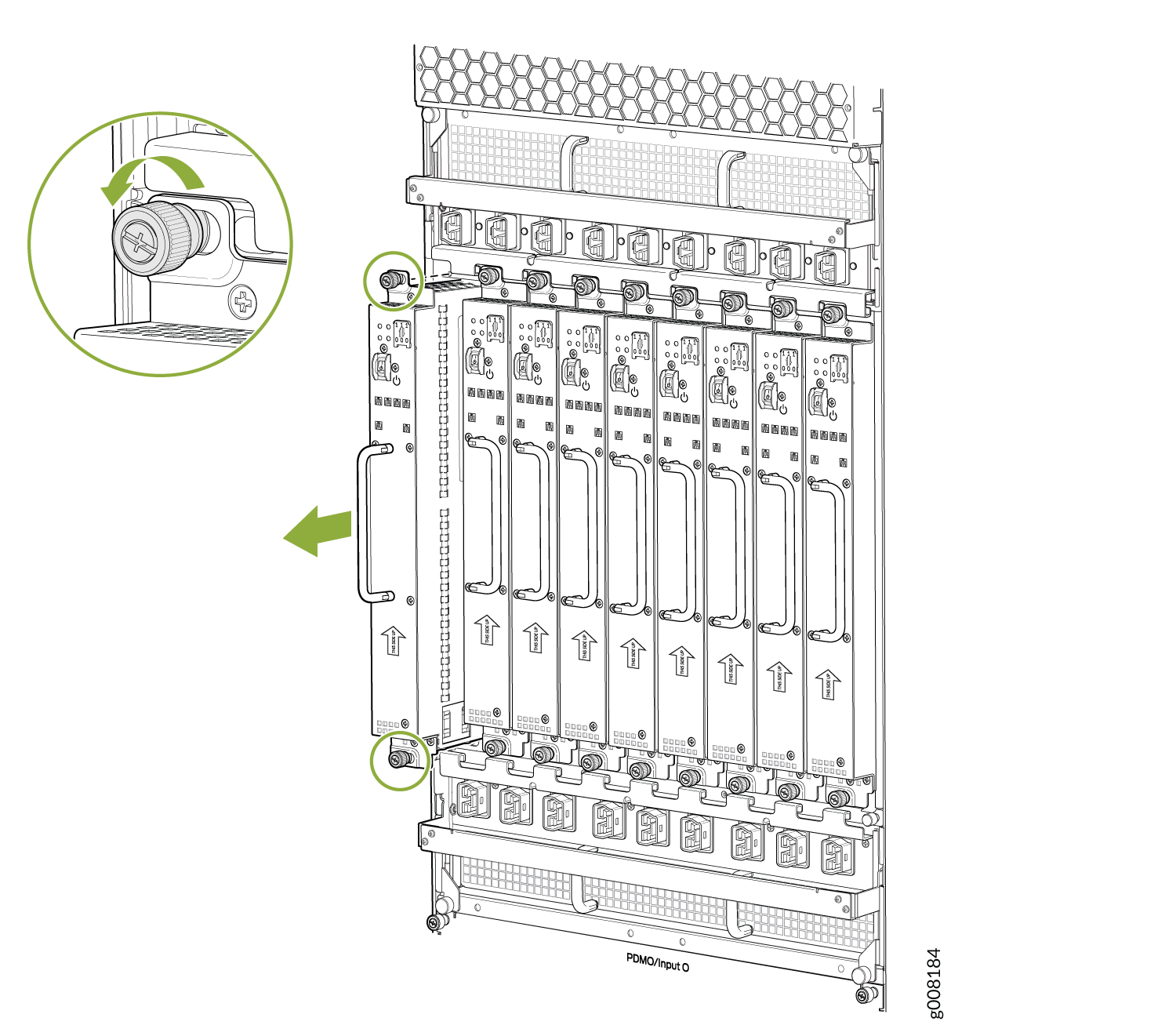

To remove a three-phase wye AC PDM:

Each PDM slot not occupied by a AC PDM must be covered by a PDM blank panel.

Installing an MX2000 Router Three-Phase Wye AC Power Distribution Module

Each three-phase wye AC PDM weighs approximately 12 lb (5.44 kg). To install a three-phase wye AC PDM:

Before performing AC power procedures, ensure that power is removed from the AC circuit. To ensure that all power is off, locate the circuit breaker on the panel board that services the AC circuit, switch the circuit breaker to the off position, and tape the switch handle of the circuit breaker in the off position.

To maintain proper cooling and prevent thermal shutdown of the operating power supply unit, each PDM slot must contain either a PDM or a blank panel. If you remove a PDM, you must install a replacement PDM or a blank panel shortly after the removal.

After powering off a PDM, wait at least 60 seconds before turning the circuit breaker back on.

The PDMs are hot swappable in a redundant configuration. However, you cannot convert to a DC configuration while the system is on.

Replacing an MX2008 Three-Phase Wye AC Power Cord

The MX2008 router has either one redundant PDM or two redundant PDMs. An AC power supply cord on a redundant PDM is hot-insertable and hot-removable. When a redundant PDM is powered down, the other PDM automatically assumes the entire electrical load for the router. If you have only one PDM, you must power off the system before removing the AC power supply cord.

Removing an MX2008 Three-Phase Wye AC Power Cord

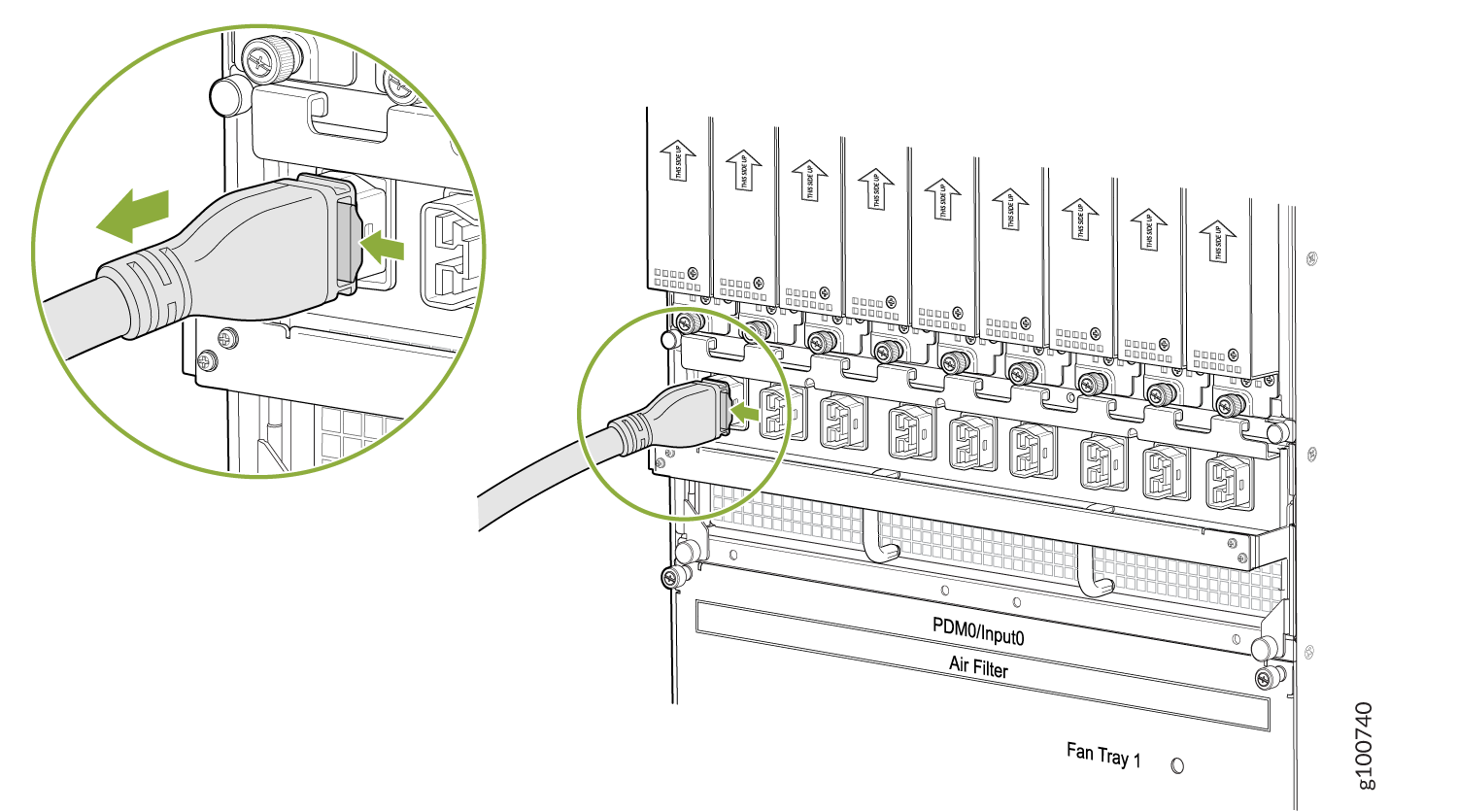

To remove a three-phase wye AC power cord:

Installing an MX2008 Three-Phase Wye AC Power Cord

To install a three-phase wye AC power cord:

Replacing an MX2008 DC Power Supply Module (-48 V)

- Removing an MX2008 DC Power Supply Module (-48 V)

- Installing an MX2008 DC Power Supply Module (-48 V)

Removing an MX2008 DC Power Supply Module (-48 V)

Before you remove a PSM, be aware of the following:

To maintain proper cooling and prevent thermal shutdown of the operating PSM, each PSM slot must contain either a PSM or a blank panel. If you remove a PSM, you must install a replacement PSM or a blank panel shortly after the removal.

After powering off a PSM, wait at least 60 seconds before turning it back on.

To remove a DC PSM (see Figure 27):

The DC PSM is hot-swappable, with a minimum number of PSMs installed.

Installing an MX2008 DC Power Supply Module (-48 V)

Before you install a PSM, be aware of the following:

The DC PSM is hot-swappable when a minimum number of PSMs installed and operational.

The DC PSMs have no circuit breakers that can physically disconnect DC line from the router. After DC feeds have been connected to the PDM, the DC voltage is always present on the power midplane and is distributed to the PSM connectors on the power midplane.

To maintain proper cooling and prevent thermal shutdown of the operating PSM, each PSM slot must contain either a PSM or a blank panel. If you remove a PSM, you must install a replacement PSM or a blank panel shortly after the removal.

After powering on a PSM, wait at least 60 seconds before turning it back off.

To install a DC PSM (see Figure 28):

Replacing an MX2008 DC Power Distribution Module Cable (-48 V)

- Disconnecting an MX2008 DC Power Distribution Module Cable

- Connecting an MX2008 DC Power Distribution Module Cable (-48 V)

Disconnecting an MX2008 DC Power Distribution Module Cable

Before performing DC power procedures, disconnect all power sources. To ensure that all power is off, locate the circuit breaker on the panel board that services the DC circuit, switch the circuit breaker to the OFF position, and tape the switch handle of the circuit breaker in the OFF position.

To disconnect a power cable for a DC PDM:

- Switch off the dedicated customer-site circuit breaker for the PDM being removed. Follow your site's procedures for ESD.

- Make sure that the voltage across the DC power source cable leads is 0 V and that there is no chance that the cables might become active during the removal process.

- Verify that the –48V LED on the PDM is not lit.

- Remove the power cable from the external DC power source.

- Attach an electrostatic discharge (ESD) grounding strap to your bare wrist, and connect the strap to one of the ESD points on the chassis.

- Remove the clear plastic cover protecting the terminal studs on the faceplate.

- Remove the nut and washers from each of the terminal studs. (Use a 7/16-in. [11 mm] nut driver or socket wrench.)

- Remove the cable lug from the terminal studs.

- Carefully move the power cable out of the way.

- Replace the clear plastic cover protecting the terminal studs on the faceplate.

Connecting an MX2008 DC Power Distribution Module Cable (-48 V)

Before performing DC power procedures, disconnect all power sources. To ensure that all power is off, locate the circuit breaker on the panel board that services the DC circuit, switch the circuit breaker to the OFF position, and tape the switch handle of the circuit breaker in the OFF position.

To connect a power cable for a DC PDM:

Replacing an MX2000 DC Power Supply Module (240 V China)

- Removing an MX2000 Router DC Power Supply Module (240 V China)

- Installing an MX2000 Router DC Power Supply Module (240 V China)

Removing an MX2000 Router DC Power Supply Module (240 V China)

Before you remove a PSM, be aware of the following:

To maintain proper cooling and prevent thermal shutdown of the operating PSM, each PSM slot must contain either a PSM or a blank panel. If you remove a PSM, you must install a replacement PSM or a blank panel shortly after the removal.

After powering off a PSM, wait at least 60 seconds before turning it back on.

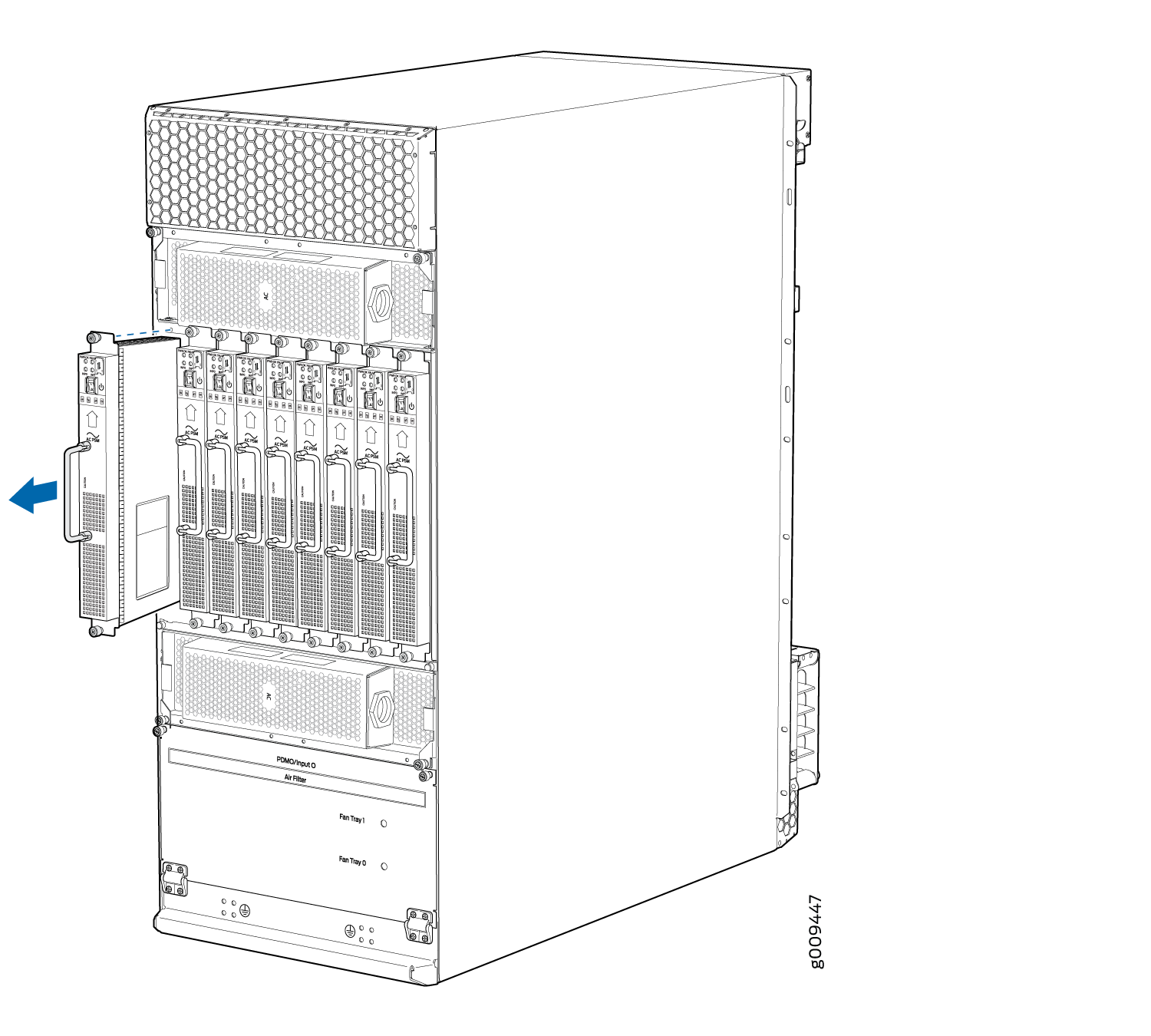

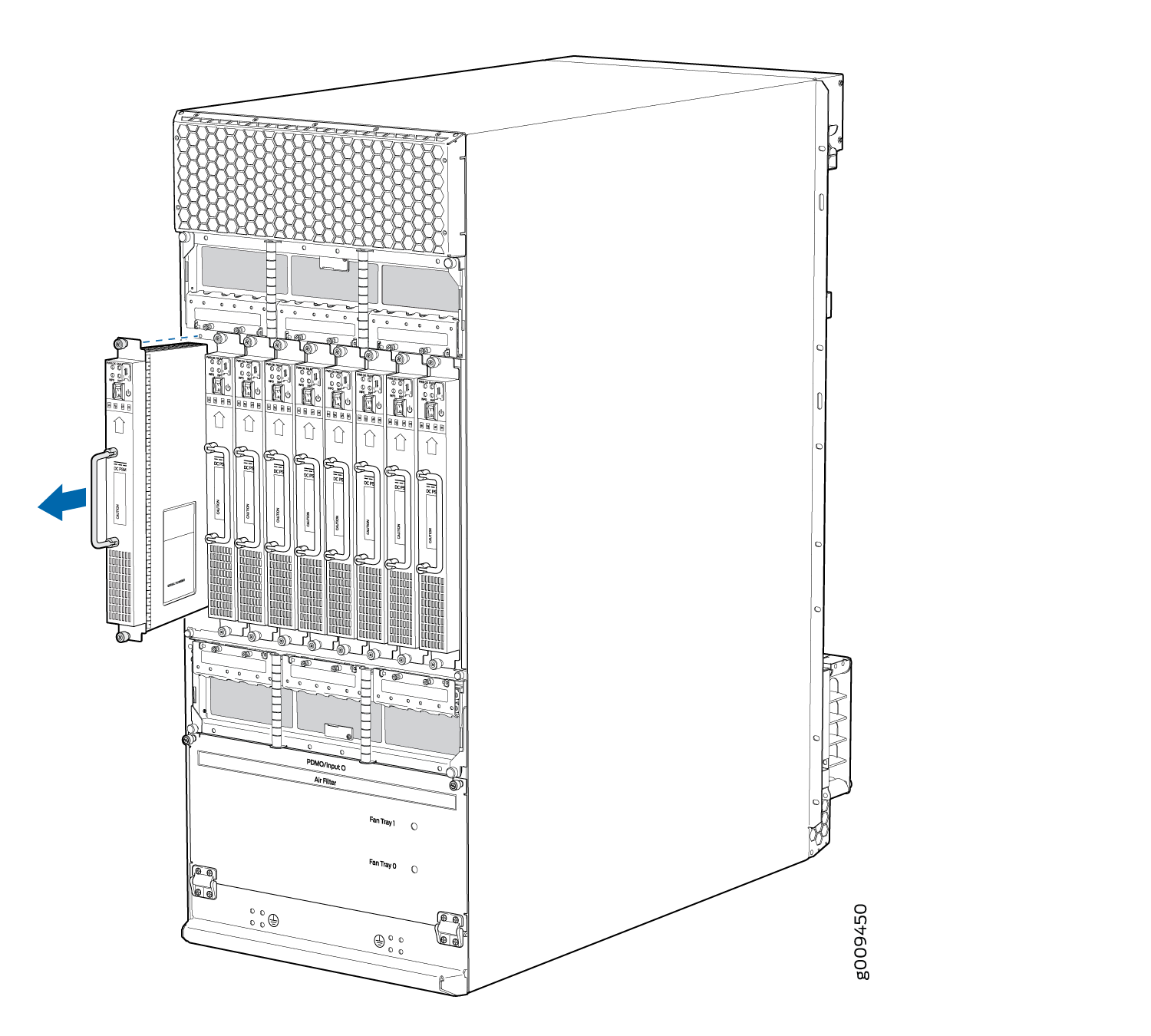

To remove a DC PSM (see Figure 30 and Figure 30):

The minimum number of DC PSMs change, based on the configuration.

See Also

Installing an MX2000 Router DC Power Supply Module (240 V China)

Before you install a DC PSM (240 V China), be aware of the following:

The DC PSM is hot-swappable when a minimum number of PSMs installed and operational.

The DC PSMs have no circuit breakers that can physically disconnect DC current from the router. After DC feeds have been connected to the PDM, the DC voltage is always present on the power midplane and is distributed to the PSM connectors on the power midplane.

To maintain proper cooling and prevent thermal shutdown of the operating PSM, each PSM slot must contain either a PSM or a blank panel. If you remove a PSM, you must install a replacement PSM or a blank panel shortly after the removal.

After powering on a PSM, wait at least 60 seconds before turning it back off.

To install a DC PSM (see Figure 31):

Replacing an MX2000 DC Power Distribution Module (240 V China)

- Removing an MX2000 Router DC Power Distribution Module (240 V China)

- Installing an MX2000 Router DC Power Distribution Module (240 V China)

- Connecting an MX2000 DC Router Power Distribution Module (240 V China) Cable

Removing an MX2000 Router DC Power Distribution Module (240 V China)

Before you remove a PDM, be aware of the following:

The minimum number of PDMs must be present in the router at all times.

Before performing DC power procedures, disconnect all power sources. To ensure that all power is off, locate the circuit breaker on the panel board that services the DC circuit, switch the circuit breaker to the OFF position, and tape the switch handle of the circuit breaker in the OFF position.

To maintain proper cooling and prevent thermal shutdown of the operating power supply unit, each PDM slot must contain either a PDM or a blank panel. If you remove a PDM, you must install a replacement PDM or a blank panel shortly after the removal.

After powering off a PDM, wait at least 60 seconds before turning the circuit breaker back on.

Installing an MX2000 Router DC Power Distribution Module (240 V China)

Before performing DC power procedures, disconnect all power sources. To ensure that all power is off, locate the circuit breaker on the panel board that services the DC circuit, switch the circuit breaker to the off position, and tape the switch handle of the circuit breaker in the off position.

To install a DC power distribution module (PDM) in an MX2000 Router:

Connecting an MX2000 DC Router Power Distribution Module (240 V China) Cable

Before performing DC power procedures, disconnect all power sources. To ensure that all power is OFF, locate the circuit breaker on the panel board that services the DC circuit, switch the circuit breaker to the OFF position, and tape the switch handle of the circuit breaker in the OFF position.

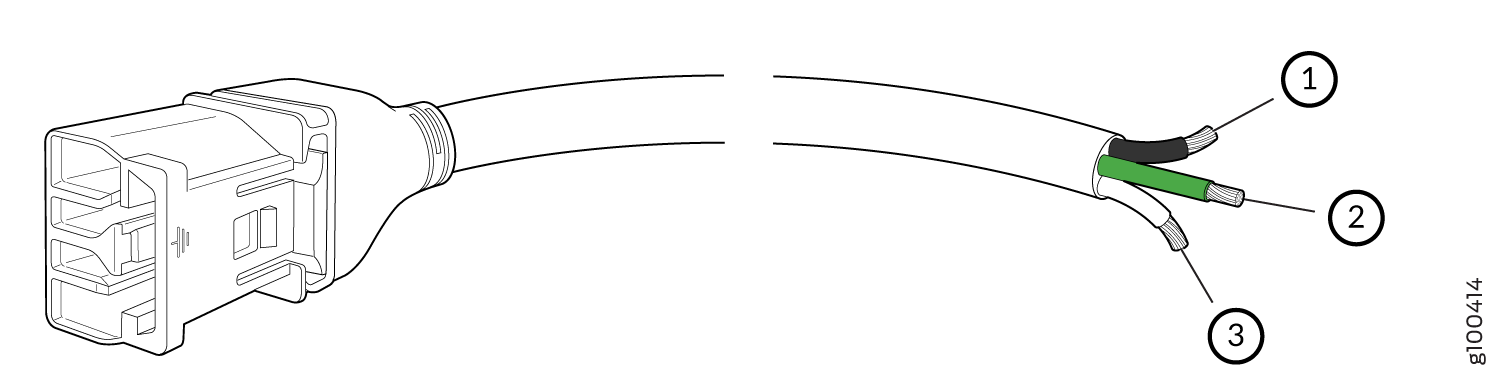

To connect the DC (240 V China) source power cables (CBL-PWR-240V-CH) to the router:

Replacing an MX2000 High-Voltage Second-Generation Universal (HVAC/HVDC) Power Supply Module

- Removing an MX2000 Router High-Voltage Second-Generation Universal (HVAC/HVDC) Power Supply Module

- Installing an MX2000 Router High-Voltage Universal (HVAC/HVDC) Power Supply Module

Removing an MX2000 Router High-Voltage Second-Generation Universal (HVAC/HVDC) Power Supply Module

Before you remove a PSM, be aware of the following:

To maintain proper cooling and prevent thermal shutdown of the operating PSM, each PSM slot must contain either a PSM or a blank panel. If you remove a PSM, you must install a replacement PSM or a blank panel shortly after the removal.

After powering off a PSM, wait at least 60 seconds before turning it back on.

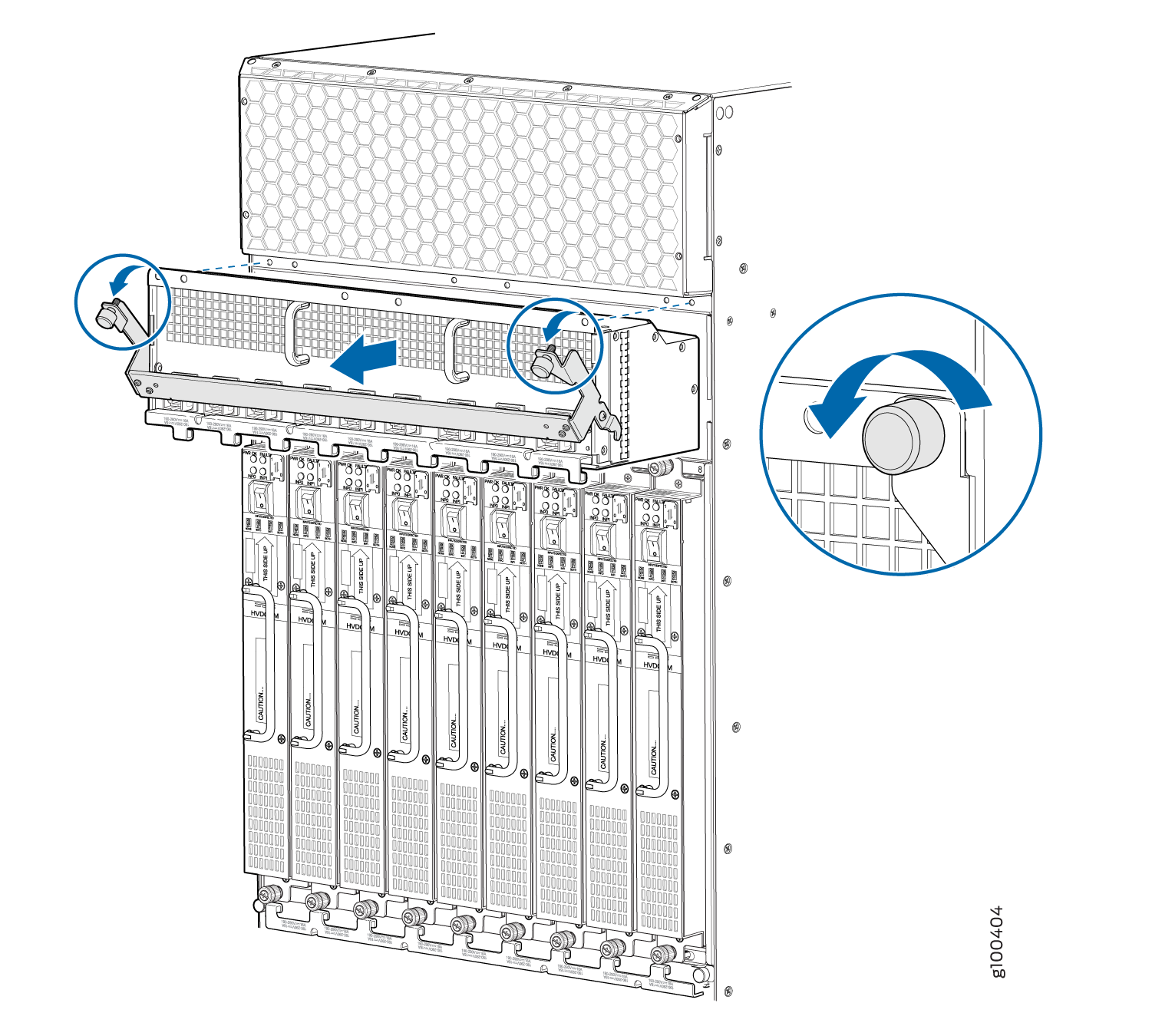

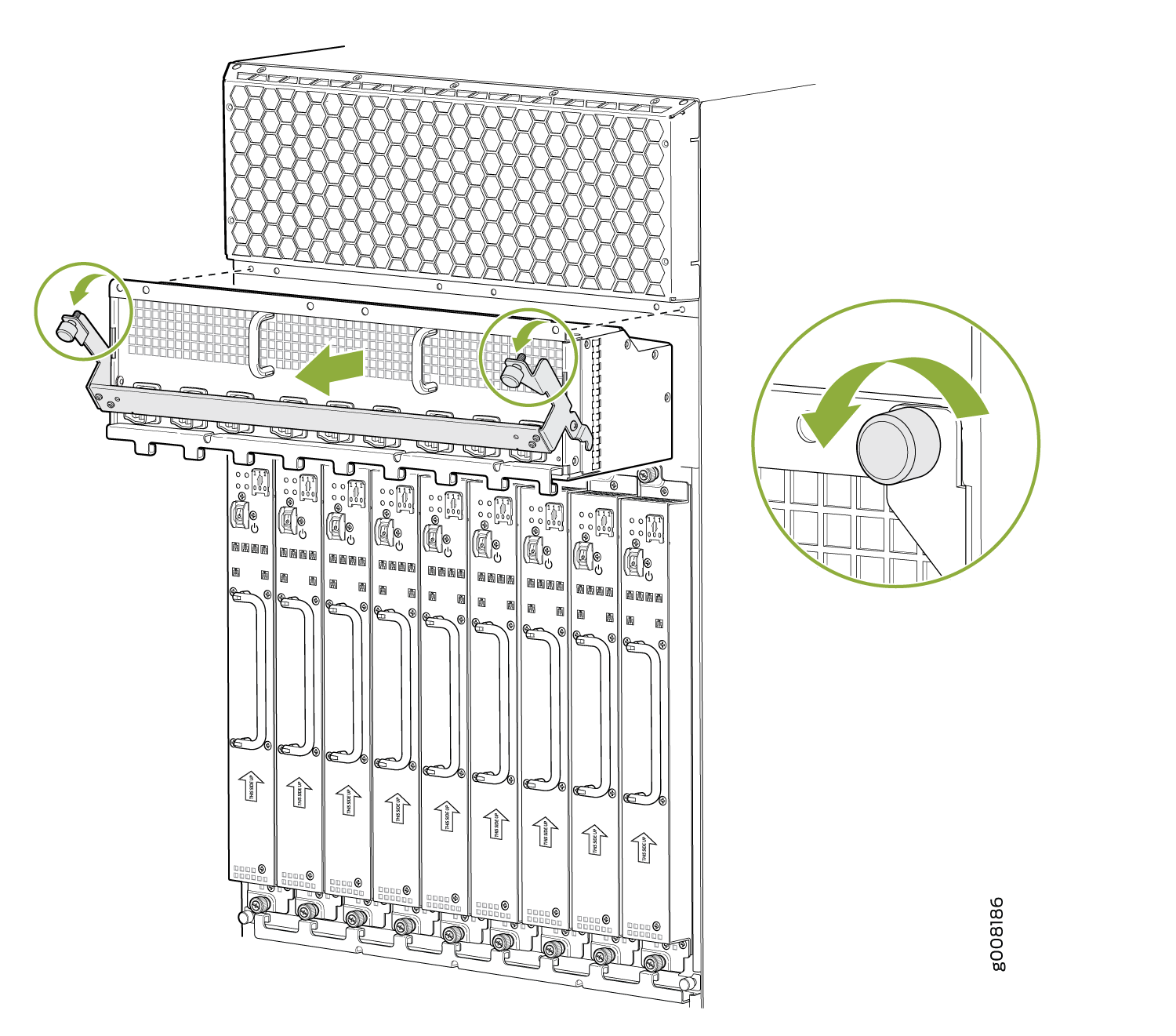

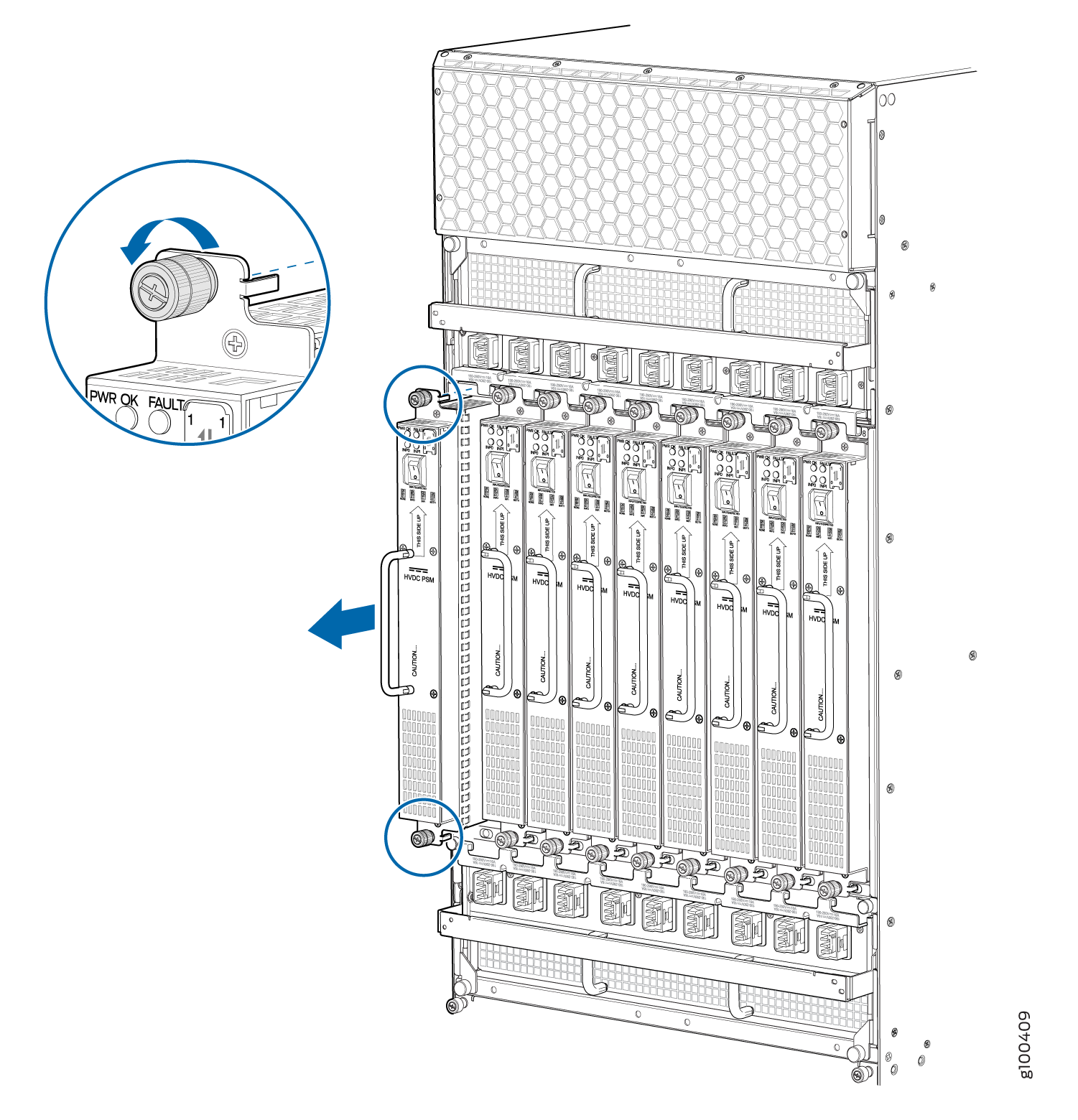

To remove a universal HVAC/HVDC PSM (see Figure 38, Figure 39, and Figure 40):

The minimum number of PSMs change, based on the configuration.

See Also

Installing an MX2000 Router High-Voltage Universal (HVAC/HVDC) Power Supply Module

Before you install a universal (HVAC/HVDC) PSM, be aware of the following:

The universal (HVAC/HVDC) PSM is hot-swappable when a minimum number of PSMs installed and operational.

Depending on whether you are connecting to AC or DC power, these warnings apply to the universal HVAC/HVDC power distribution module (PDM):

The DC PSMs have no circuit breakers that can physically disconnect DC current from the router. After DC feeds have been connected to the PDM, the DC voltage is always present on the power midplane and is distributed to the PSM connectors on the power midplane.

The AC PSMs have no circuit breakers that can physically disconnect AC current from the router. After AC feeds have been connected to the PDM, the AC voltage is always present on the power midplane and is distributed to the PSM connectors on the power midplane.

To maintain proper cooling and prevent thermal shutdown of the operating PSM, each PSM slot must contain either a PSM or a blank panel. If you remove a PSM, you must install a replacement PSM or a blank panel shortly after the removal.

After powering on a PSM, wait at least 60 seconds before turning it back off.

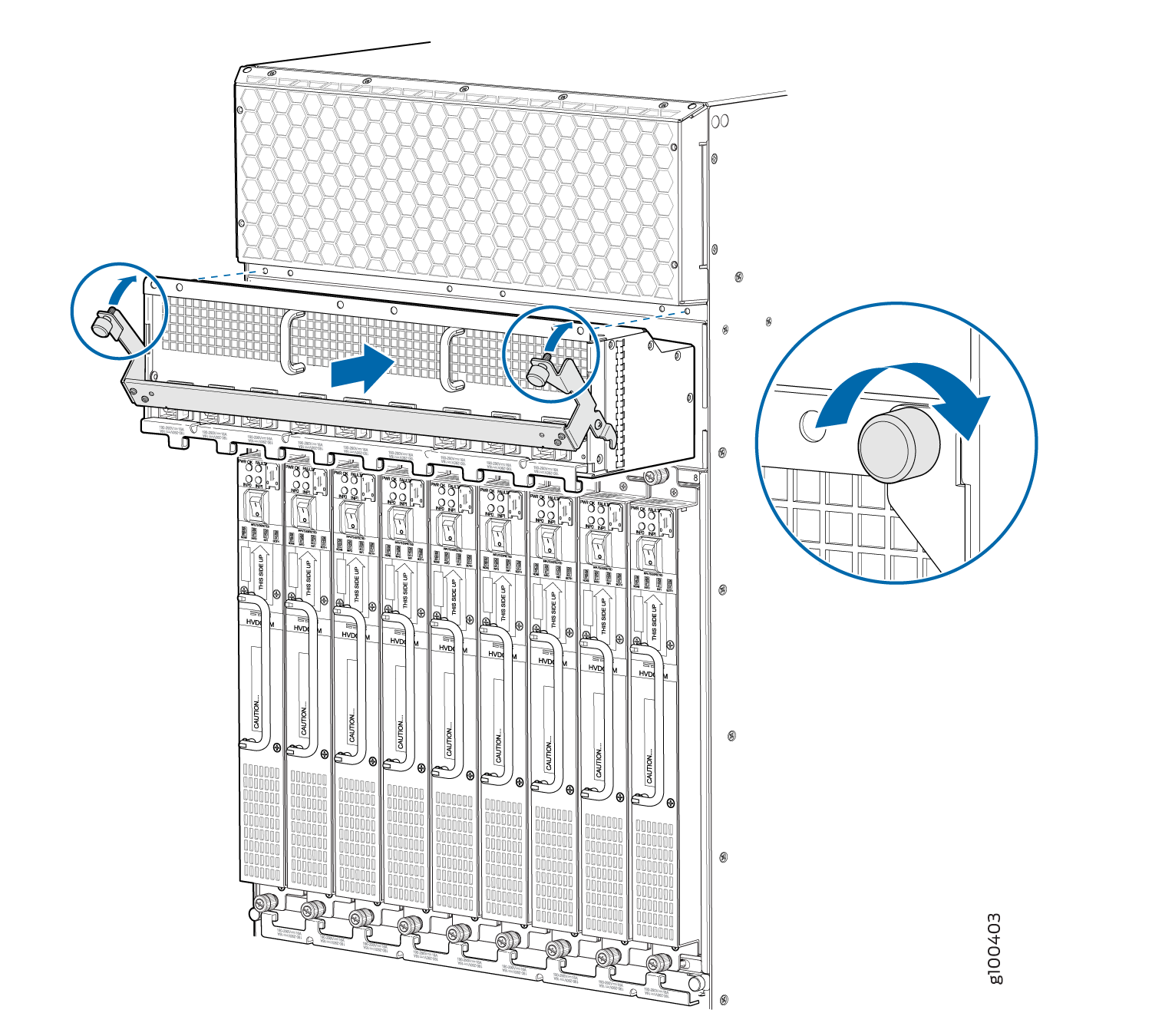

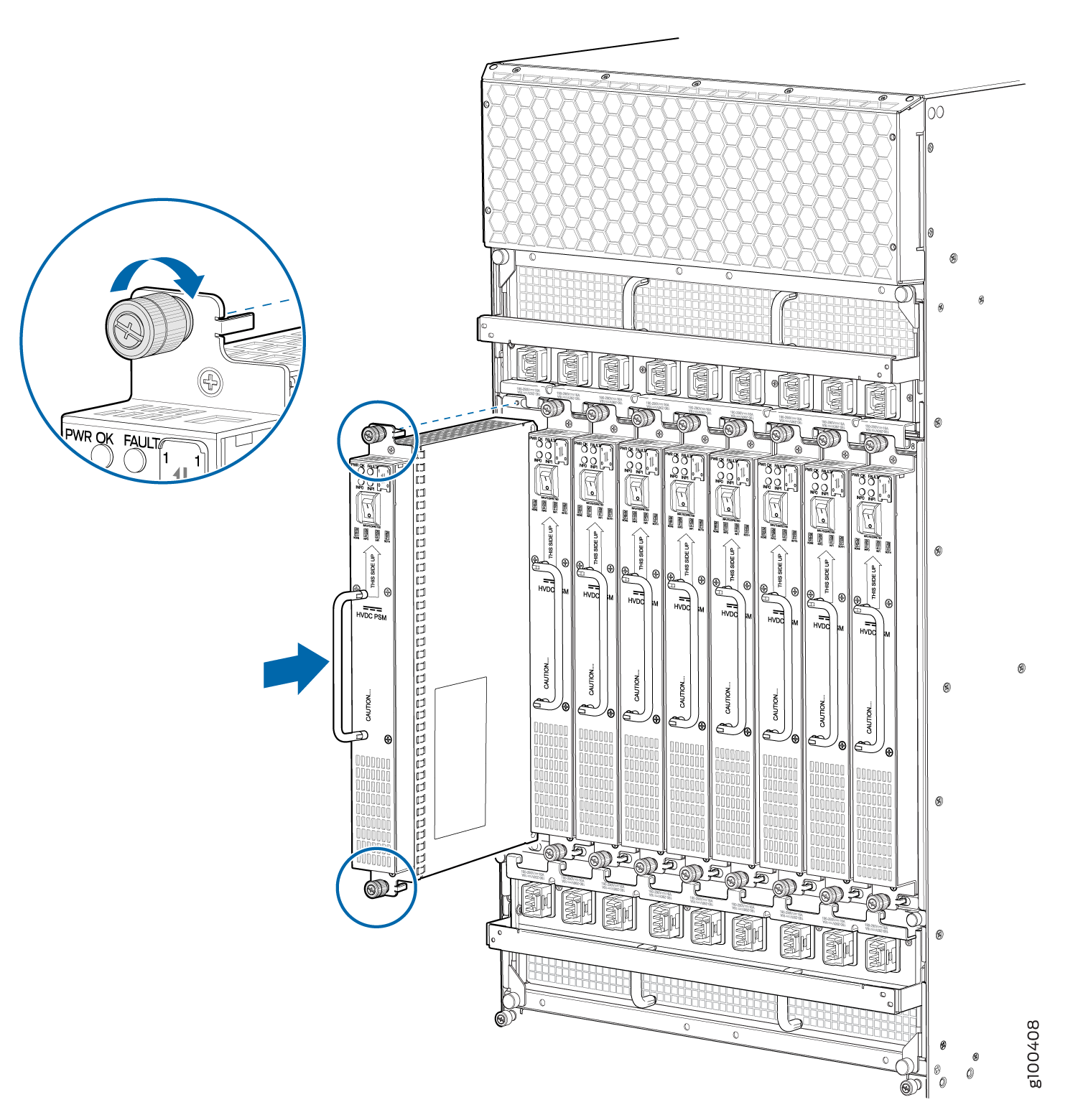

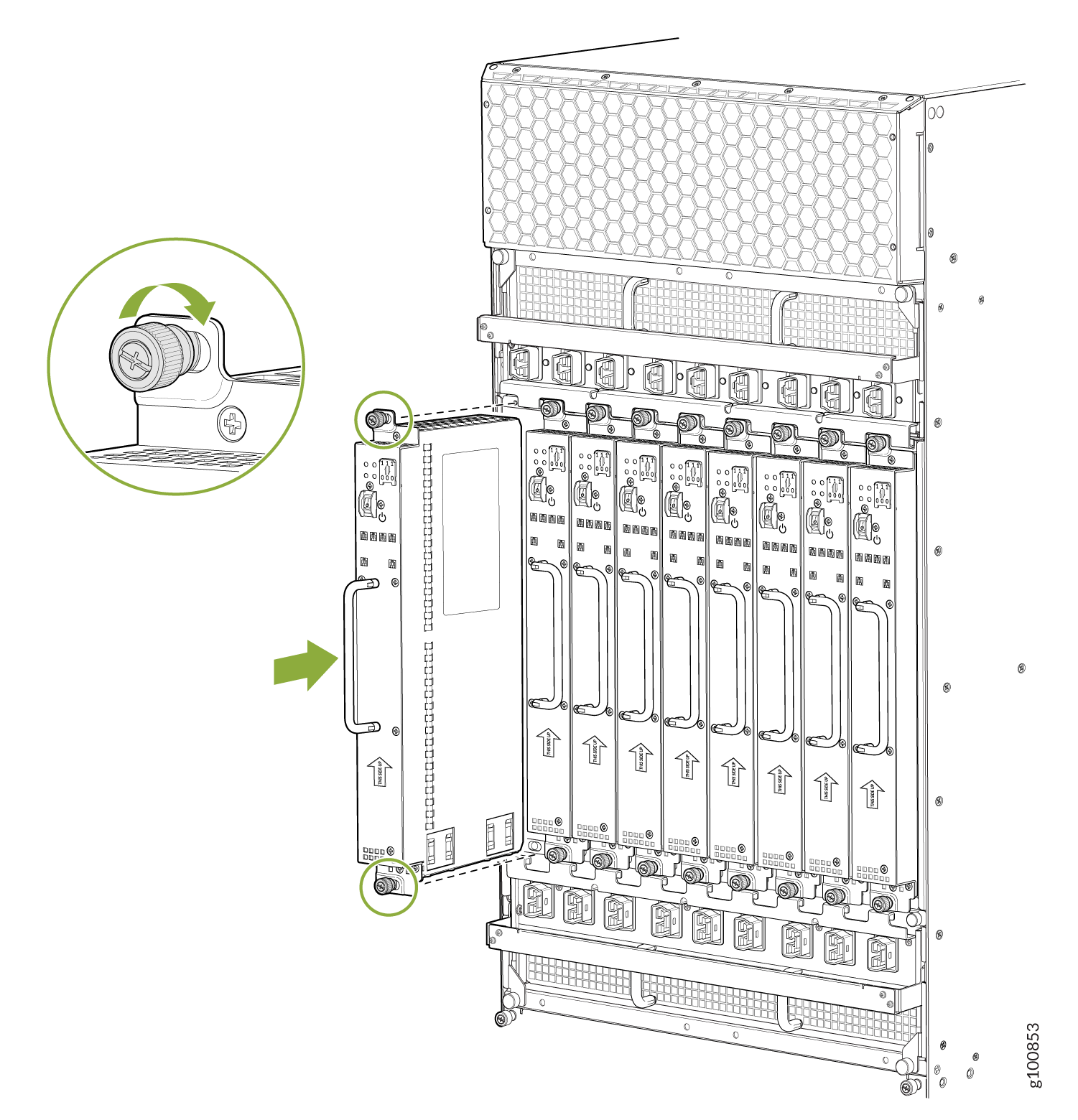

To install a universal (HVAC/HVDC) PSM (see Figure 41, Figure 42, and Figure 43):

Replacing an MX2000 High-Voltage Universal (HVAC/HVDC) Power Distribution Module

- Installing an MX2000 Router High-Voltage Universal (HVAC/HVDC) Power Distribution Module

- Removing an MX2000 Router High-Voltage Second Generation Universal (HVAC/HVDC) Power Distribution Module

Installing an MX2000 Router High-Voltage Universal (HVAC/HVDC) Power Distribution Module

Depending on whether you are connecting to AC or DC power, these warnings apply to the universal HVAC/HVDC power distribution module (PDM):

Before performing DC power procedures, disconnect all power sources. To ensure that all power is off, locate the circuit breaker on the panel board that services the DC circuit, switch the circuit breaker to the off position, and tape the switch handle of the circuit breaker in the off position.

Before performing AC power procedures, disconnect all power sources. To ensure that all power is OFF, locate the circuit breaker on the panel board that services the AC circuit, switch the circuit breaker to the OFF position, and tape the switch handle of the circuit breaker in the OFF position.

Before working on the device or near power supplies, unplug all the power cords from an AC-powered device.

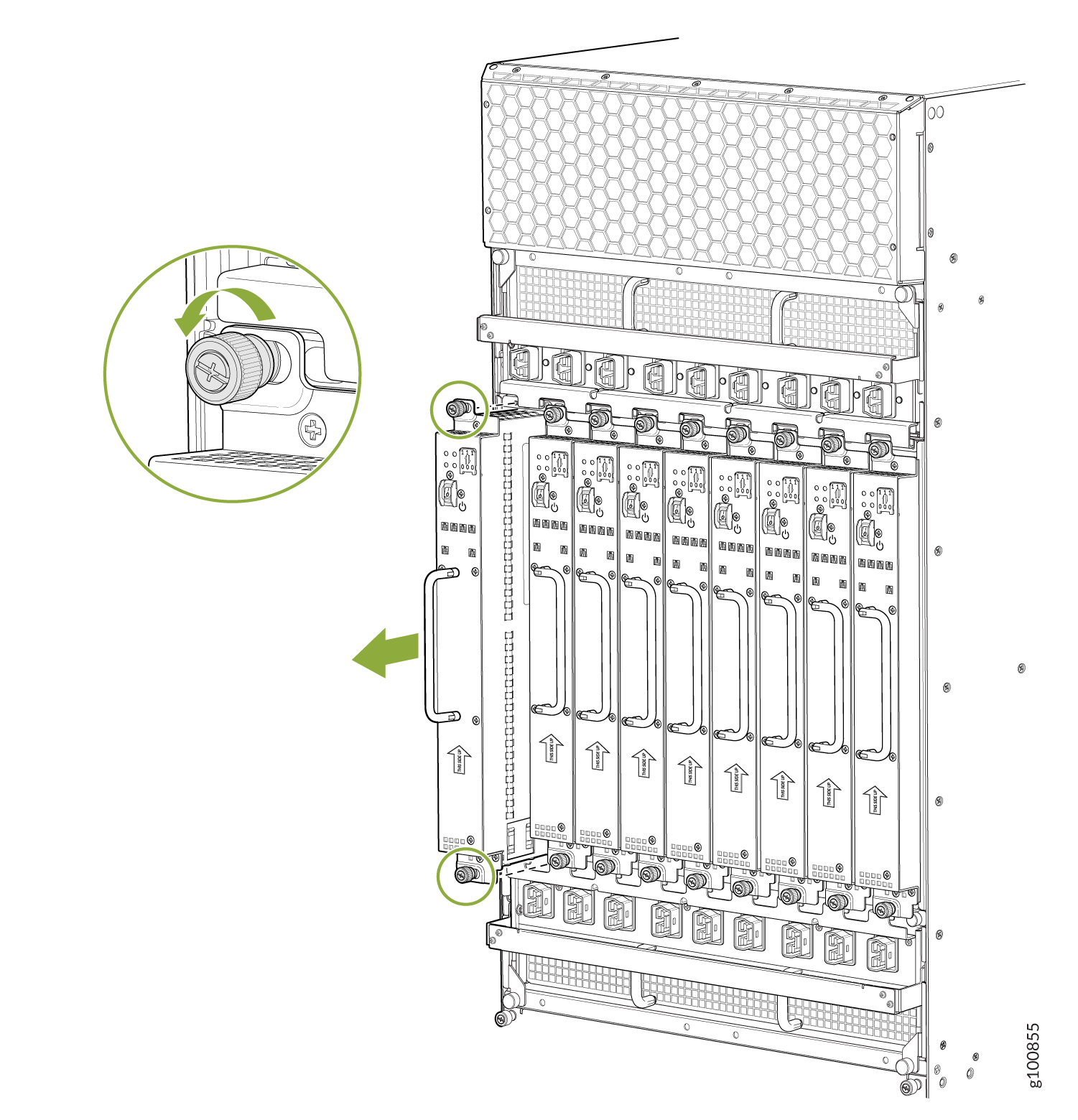

To install a universal HVAC/HVDC power distribution module (PDM) in an MX2000 Router:

Removing an MX2000 Router High-Voltage Second Generation Universal (HVAC/HVDC) Power Distribution Module

Before you remove a PDM, be aware of the following:

The minimum number of PDMs must be present in the router at all times while it is operating.

Depending on whether you are connecting to AC or DC power, these warnings apply to the universal HVAC/HVDC power distribution module (PDM):

Before performing DC power procedures, disconnect all power sources. To ensure that all power is off, locate the circuit breaker on the panel board that services the DC circuit, switch the circuit breaker to the OFF position, and tape the switch handle of the circuit breaker in the OFF position.

These warnings apply to the HVAC/HVDC universal PDM:

Before performing AC power procedures, disconnect all power sources. To ensure that all power is OFF, locate the circuit breaker on the panel board that services the AC circuit, switch the circuit breaker to the OFF position, and tape the switch handle of the circuit breaker in the OFF position.

Before working on the device or near power supplies, unplug all the power cords from an AC-powered device.

To maintain proper cooling and prevent thermal shutdown of the operating power supply unit, each PDM slot must contain either a PDM or a blank panel. If you remove a PDM, you must install a replacement PDM or a blank panel shortly after the removal.

After powering off a PDM, wait at least 60 seconds before turning the circuit breaker back on.