Connecting the EX4600 to Power

Connecting Earth Ground to an EX4600 Switch

To ensure proper operation and to meet electromagnetic interference (EMI) requirements, you must connect an EX4600 switch to earth ground before you connect power to the switch. You must use the protective earthing terminal on the switch chassis to connect the switch to earth ground (see Figure 1).

You must install the EX4600 switch in a restricted–access location and ensure that the chassis is always properly grounded. EX4600 switches have a two–hole protective grounding terminal provided on the left side of the chassis. EX4600 switches have a two–hole protective grounding terminal provided on the left side of the chassis. Under all circumstances, use this grounding connection to ground the chassis. For AC-powered systems, you must also use the grounding wire in the AC power cord along with the two-hole grounding lug connection. This tested system meets or exceeds all applicable EMC regulatory requirements with the two-hole protective grounding terminal.

Ensure that a licensed electrician has attached an appropriate grounding lug to the grounding cable you supply. Using a grounding cable with an incorrectly attached lug can damage the switch.

Mount your switch in the rack or cabinet before attaching the grounding lug to the switch. See Mounting an EX4600 Switch in a Rack or Cabinet.

Ensure that you have the parts and tools listed in Table 1available:

| Item | Description |

|---|---|

| Earthing terminal location | Left side of the chassis |

| Protective earthing terminal bracket | This bracket attaches to the EX4600 switch chassis through the left front mounting bracket, providing a protective earthing terminal for the switch. |

| Grounding cable requirements | 14 AWG (2 mm²), minimum 90° C wire, or as permitted by the local code—not provided |

| Grounding lug specifications | Panduit LCD10-10A-L or equivalent—not provided |

| Screws to secure the grounding lug | Two SAE 10-32 screws and washers—not provided |

| Tools required |

Number 2 Phillips (+) screwdriver—not provided Electrostatic discharge (ESD) grounding strap—not provided |

To connect earth ground to a EX4600 switch:

See Also

Connecting AC Power to an EX4600 Switch

Ensure that you have a power cord appropriate for your geographical location available to connect AC power to the switch.

Before you begin connecting AC power to the switch:

Ensure that you have taken the necessary precautions to prevent electrostatic discharge (ESD) damage (see Prevention of Electrostatic Discharge Damage).

Ensure that you have connected the device chassis to earth ground.

CAUTION:For installations that require a separate grounding conductor to the chassis, have a licensed electrician complete this connection before you connect the switch to power. For instructions on connecting earth ground, see Connect Earth Ground to an EX Series Switch.

Install the power supply in the chassis. For instructions on installing a power supply in an EX4600 switch, see Installing a Power Supply in an EX4600 Switch.

The EX4600 is shipped from the factory with two power supplies. Each power supply is a hot-removable and hot-insertable field-replaceable unit (FRU) when the second power supply is installed and running. You can install replacement power supplies in the two slots next to the fan modules without powering off the switch or disrupting the switching function.

Each power supply must be connected to a dedicated power source outlet.

To connect AC power to an EX4600 switch:

See Also

Connecting DC Power to an EX4600 Switch

Before you begin connecting DC power to the switch:

Ensure that you have taken the necessary precautions to prevent electrostatic discharge (ESD) damage (see Prevention of Electrostatic Discharge Damage).

Ensure that you have connected the switch chassis to earth ground.

CAUTION:Before you connect power to the switch, a licensed electrician must attach a cable lug to the grounding and power cables that you supply. A cable with an incorrectly attached lug can damage the switch (for example, by causing a short circuit).

To meet electromagnetic interference (EMI) requirements and to ensure proper operation, you must connect the chassis to earth ground before you connect it to power. For installations that require a separate grounding conductor to the chassis, use the protective earthing terminal on the switch chassis to connect to the earth ground. For instructions on connecting earth ground, see Connecting Earth Ground to an EX4600 Switch.

Install the power supply in the chassis. For instructions on installing a power supply in an EX4600 switch, see Installing a Power Supply in an EX4600 Switch.

Ensure that you have the following parts and tools available:

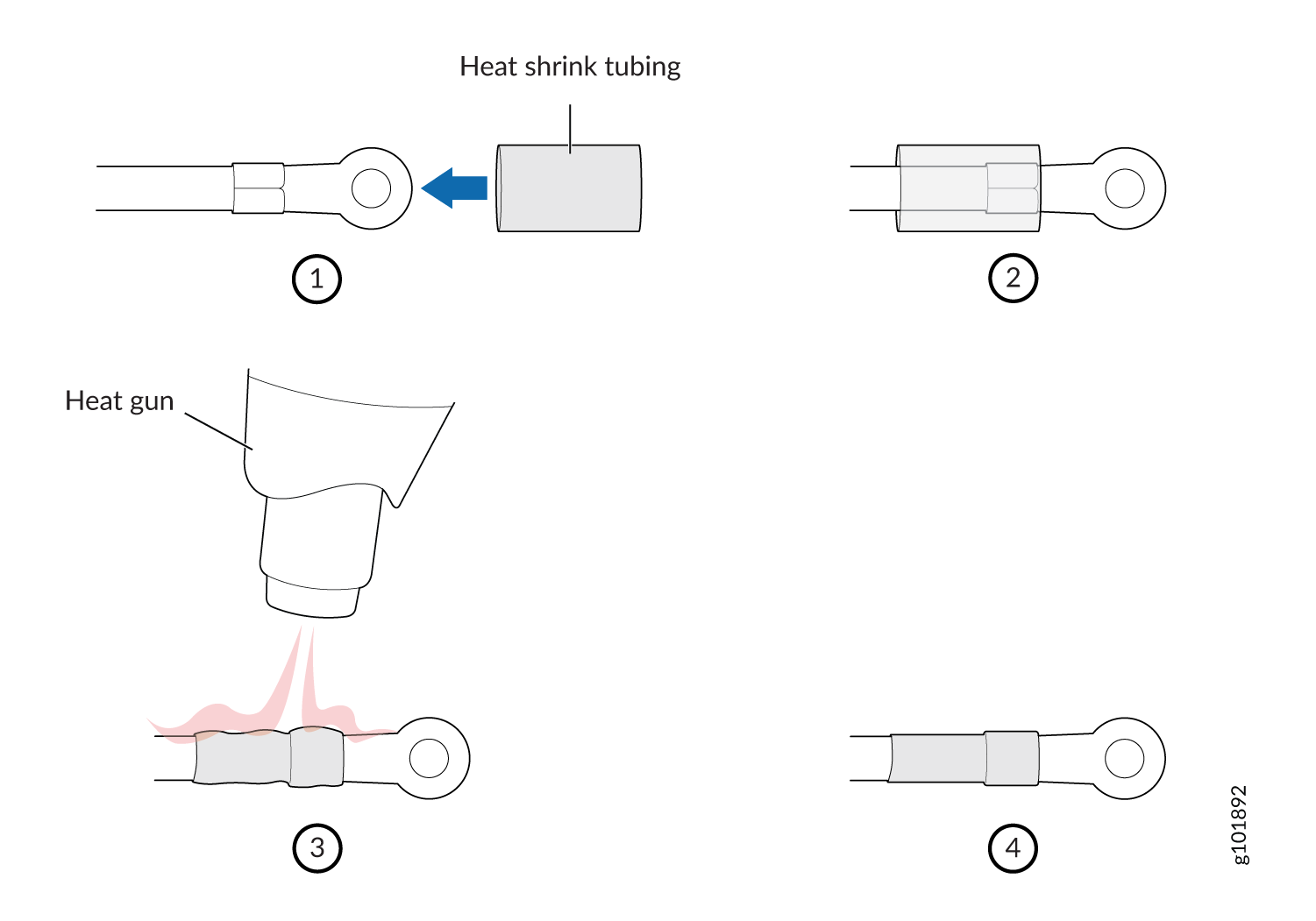

DC power source cables (14–16 AWG) with ring lug (Molex 190700069 or equivalent) (not provided)

Phillips (+) screwdriver, number 2 (not provided)

Multimeter (not provided)

The EX4600 is shipped from the factory with two power supplies. Each power supply is a hot-removable and hot-insertable field-replaceable unit (FRU) when the second power supply is installed and running. You can install replacement power supplies in the two slots next to the fan modules without powering off the switch or disrupting the switching function.

DC-powered EX4600 switches are intended for installation only in a restricted access location.

The battery returns of the DC power supply should be connected as an isolated DC return (DC-I).

To connect DC power to an EX4600 switch: