ON THIS PAGE

Tools and Parts Required for MX480 Router Grounding and Power Connections

Connecting Power to an AC-Powered MX480 Router with Normal-Capacity Power Supplies

Connecting Power to a DC-Powered MX480 Router with Normal Capacity Power Supplies

Powering On a DC-Powered MX480 Router with Normal Capacity Power Supplies

Connecting the MX480 to Power

Tools and Parts Required for MX480 Router Grounding and Power Connections

To ground and provide power to the router, you need the following tools and parts:

Phillips (+) screwdrivers, numbers 1 and 2

2.5-mm flat-blade (–) screwdriver

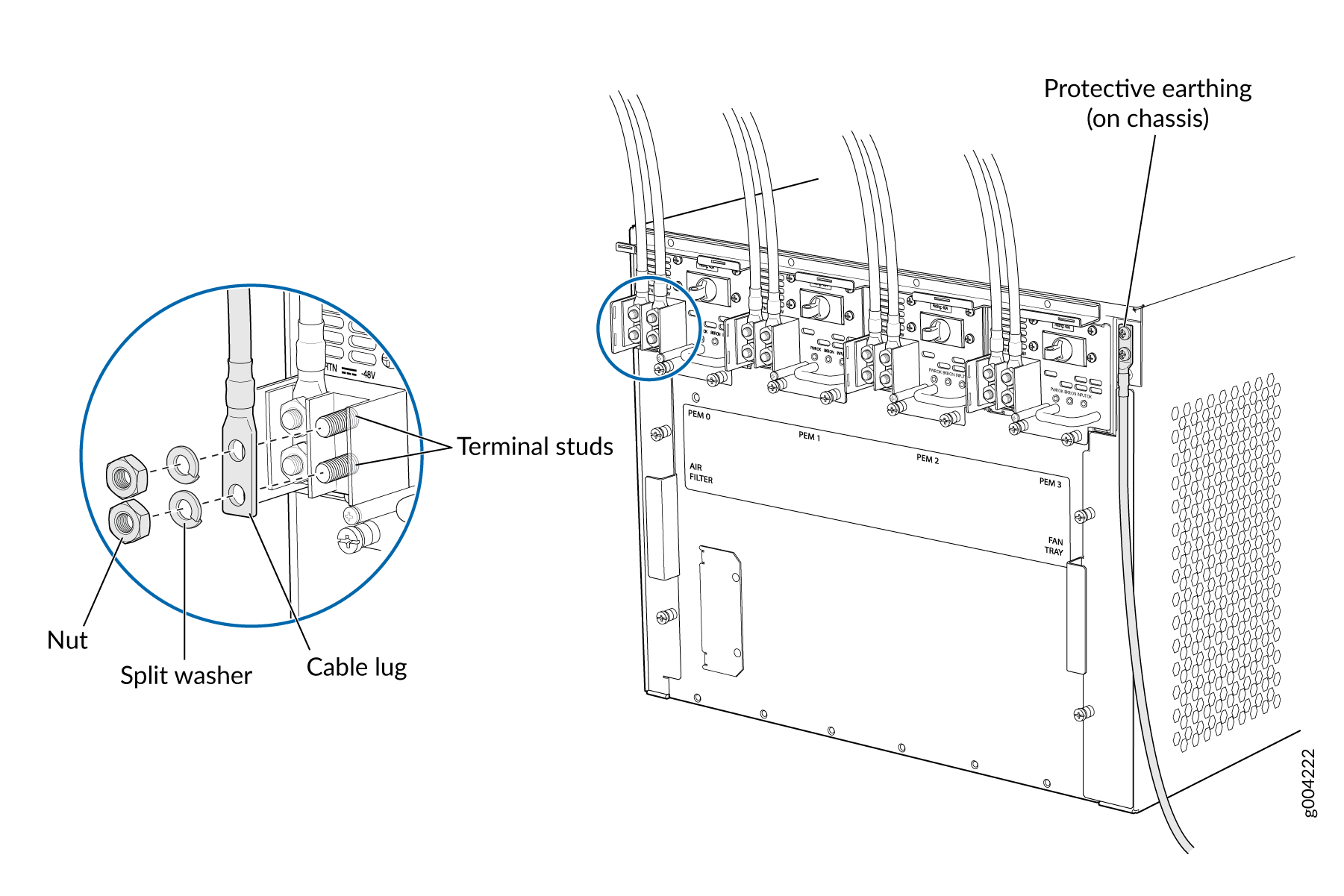

7/16-in. (11 mm) hexagonal-head external drive socket wrench, or nut driver, with a torque range between 23 lb-in. (2.6 Nm) and 25 lb-in. (2.8 Nm), for tightening nuts to terminal studs on each power supply on a DC-powered router.

Wire cutters

Electrostatic discharge (ESD) grounding wrist strap

The maximum torque rating of the terminal studs on the DC power supply is 36 lb-in. (4.0 Nm). The terminal studs may be damaged if excessive torque is applied. Use only a torque-controlled driver or socket wrench to tighten nuts on the DC power supply terminal studs. Use an appropriately-sized driver or socket wrench, with a maximum torque capacity of 50 lb-in. or less. Ensure that the driver is undamaged and properly calibrated and that you have been trained in its use. You may wish to use a driver that is designed to prevent overtorque when the preset torque level is achieved.

Grounding the MX480 Router

You ground the router by connecting a grounding cable to earth ground and then attaching it to the chassis grounding points using UNC 1/4-20 two screws. You must provide the grounding cable (cable lugs are supplied with the router). To ground the router:

- Verify that a licensed electrician has attached the cable lug provided with the router to the grounding cable.

- Attach an ESD grounding strap to your bare wrist, and connect the other end of the strap to an approved site ESD grounding point. See the instructions for your site.

- Ensure that all grounding surfaces are clean and brought to a bright finish before grounding connections are made.

- Connect the grounding cable to a proper earth ground.

- Detach the ESD grounding strap from the site ESD grounding point.

- Attach an ESD grounding strap to your bare wrist, and connect the other end of the strap to an ESD grounding point.

- Place the grounding cable lug over the grounding points on the upper rear of the chassis. The bolts are sized for UNC 1/4-20 bolts.

- Secure the grounding cable lug to the grounding points, first with the washers, then with the screws.

- Dress the grounding cable and verify that it does not touch or block access to router components, and that it does not drape where people could trip on it.

See Also

Connecting Power to an AC-Powered MX480 Router with Normal-Capacity Power Supplies

Do not mix AC and DC power supply modules within the same device. Mixing currents can damage the device.

You connect AC power to the router by attaching power cords from the AC power sources to the AC appliance inlets located on the power supplies. For power cord and AC power specifications, see AC Power Cord Specifications for the MX480 Router.

To connect the AC power cords to the router (see Figure 1):

Powering On an AC-Powered MX480 Router

To power on an AC-powered router:

Connecting Power to a DC-Powered MX480 Router with Normal Capacity Power Supplies

Do not mix AC and DC power supply modules within the same device. Mixing currents can damage the device.

Before you perform DC power procedures, ensure there is no power to the DC circuit. To ensure that all power is off, locate the circuit breaker on the panel board that services the DC circuit, switch the circuit breaker to the off position, and tape the switch handle of the circuit breaker in the off position.

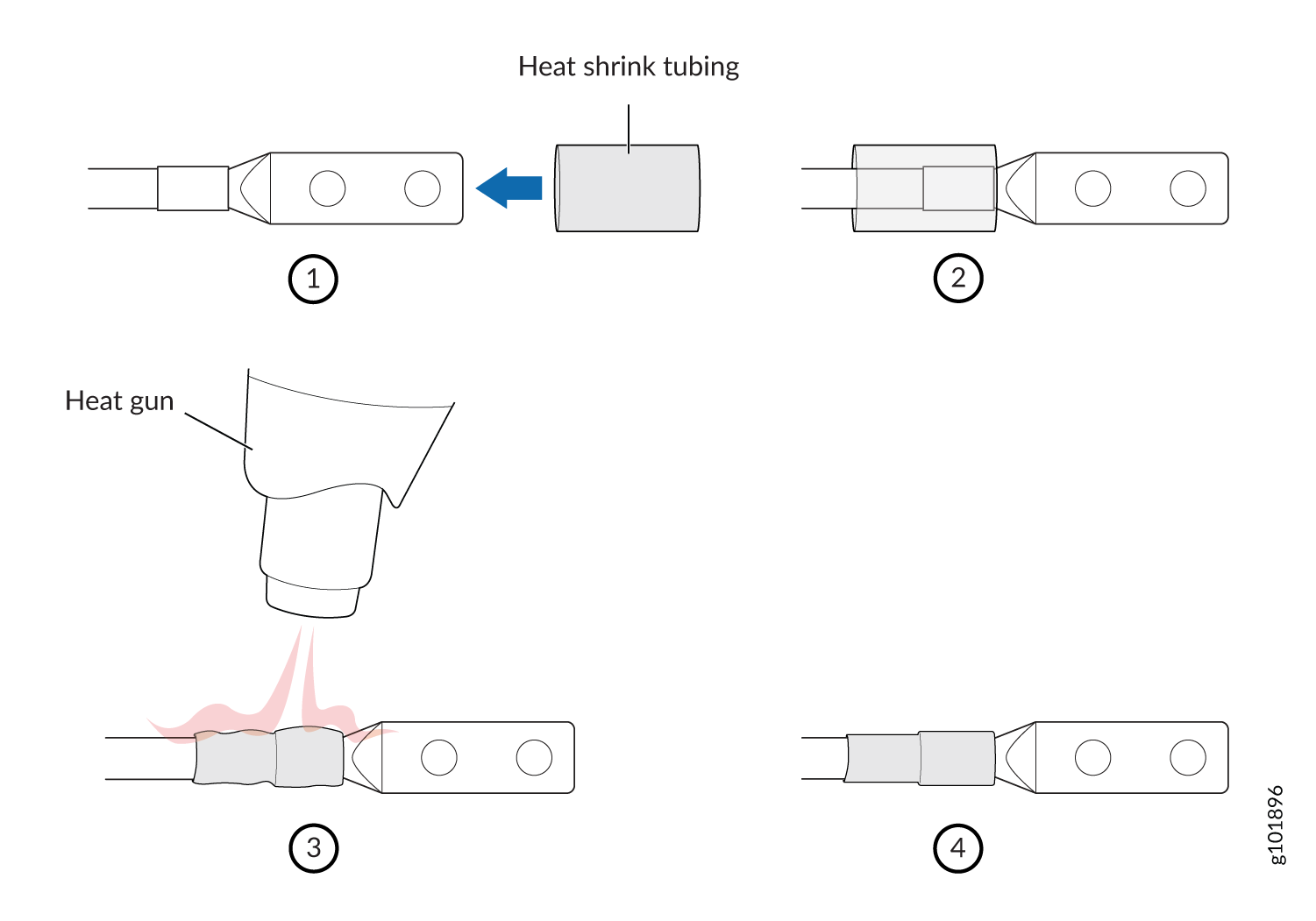

You connect DC power to the router by attaching power cables from the external DC power sources to the terminal studs on the power supply faceplates. You must provide the power cables (the cable lugs are supplied with the router).

To connect the DC source power cables to the router:

Powering On a DC-Powered MX480 Router with Normal Capacity Power Supplies

To power on a DC-powered router:

See Also

Powering Off the MX480 Router

After powering off a power supply, wait at least 60 seconds before turning it back on.

To power off the router:

Connecting an MX480 AC Power Supply Cord

To connect the AC power cord:

- Locate a replacement power cord with the type of plug appropriate for your geographical location (see AC Power Cord Specifications for the MX480 Router).

- Connect the power cord to the power supply.

- Route the power cord along the cable restraint toward the left or right corner of the chassis. If needed to hold the power cord in place, thread plastic cable ties, which you must provide, through the openings on the cable restraint.

- Verify that the power cord does not block the air exhaust and access to router components, or drape where people could trip on it.

- Attach the power cord to the AC power source, and switch on the dedicated customer site circuit breaker for the power supply. Follow the ESD and connection instructions for your site.

- Switch the AC input switch on the each power supply to the on (—) position and observe the status LEDs on the power supply faceplate. If the power supply is correctly installed and functioning normally, the AC OK and DC OK LEDs light steadily, and the PS FAIL LED is not lit.

Connecting an MX480 DC Power Supply Cable

Before you perform DC power procedures, ensure there is no power to the DC circuit. To ensure that all power is off, locate the circuit breaker on the panel board that services the DC circuit, switch the circuit breaker to the off position, and tape the switch handle of the circuit breaker in the off position.

To connect a power cable for a DC power supply: