QFX5241-64OD and QFX5241-64QD Site Guidelines and Requirements

Your QFX5241-64OD and QFX5241-64QD switches must meet the specified environmental requirements. The switches will function properly if you follow site and wiring guidelines. Ensure that your installation meets the grounding specifications and airflow clearance requirements.

QFX5241-64OD and QFX5241-64QD Environmental Requirements and Specifications

You must install the switch in a rack. House it in a dry, clean, well-ventilated, and temperature-controlled environment.

Follow these environmental guidelines:

-

The site must be as dust-free as possible. Dust can clog air intake vents and filters, thereby reducing the efficiency of the switch cooling system.

-

Maintain ambient airflow to ensure normal operation of the switch. If the switch temperature is not maintained, the temperature monitor of the switch might shut down the device. The switch shuts down to protect its hardware components. The switch might overheat in the following scenarios:

-

The airflow is blocked or restricted

-

The intake air is too warm

-

|

Description |

Tolerance |

|---|---|

|

Altitude |

With DAC cables: At 32 °F (0 °C) through 104° F (40 °C), no performance degradation occurs up to 6000 ft (1828.8 m) |

|

With optics: At 32 °F (0 °C) through 104 °F (40 °C), sea level |

|

|

Relative humidity, operating |

Normal operation ensured in the relative humidity range of 5% through 90%, noncondensing |

|

Temperature |

|

|

Seismic |

Designed to comply with Zone 4 earthquake requirements in accordance with NEBS GR-63-CORE, Issue 3. |

General Site Guidelines

Efficient device operation requires proper site planning. For the device to operate properly, you must ensure maintenance and proper layout of the equipment, rack or cabinet, and wiring closet.

To plan and create an acceptable operating environment for your device and prevent environmentally caused equipment failures:

Keep the area around the chassis free from dust and conductive material, such as metal flakes.

Follow the prescribed airflow guidelines to ensure that the cooling system functions properly. Ensure that the exhaust from other equipment does not blow into the intake vents of the device.

Follow the prescribed electrostatic discharge (ESD) prevention procedures to prevent damaging the equipment. Static discharge can cause components to fail completely or intermittently over time.

Install the device in a secure area, so that only authorized personnel can access the device.

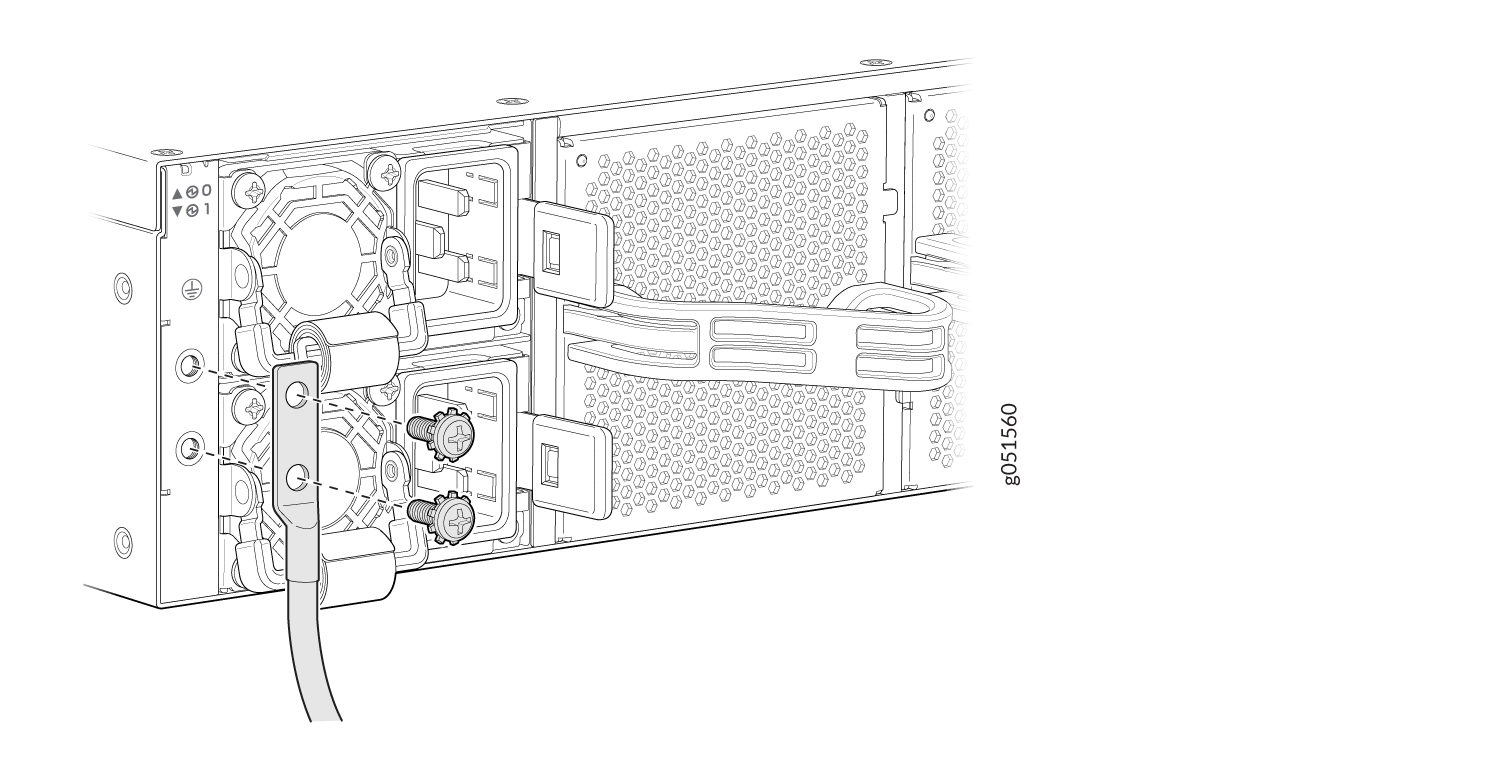

QFX5241-64OD and QFX5241-64QD Grounding Cable and Lug Specifications

For installations that need a separate chassis grounding conductor to the chassis, you must ground the chassis adequately before connecting power. Proper grounding of the chassis ensures operational correctness and compliance with safety and electromagnetic interference (EMI) requirements.

Ensure that you have a grounding cable and lug with the following specifications:

-

Grounding cable—2 AWG , minimum 90° C wire, or as permitted by the local code. (not provided)

-

Grounding lug—Panduit LCDXN2-14AF-E or equivalent grounding lug. The grounding lug attaches to the device chassis through the left-front mounting bracket, providing a protective earthing terminal for the device. (not provided)

The switch is pluggable type A equipment that is installed in a restricted-access location. The switch has a separate protective earthing terminal provided on the chassis in addition to the grounding pin of the power supply cord. You must permanently connect this separate protective earthing terminal to earth ground for installations that require a separate grounding conductor to the chassis.

To comply with GR-1089 requirements, ensure that all intrabuilding copper cabling used for SFP+ and QSFP+ ports are shielded and grounded at both ends.

Before you install the switch, a licensed electrician must attach a cable lug to the grounding cables that you supply. A cable with an incorrectly attached lug can damage the switch.

Before connecting the switch to earth ground, review the following information:

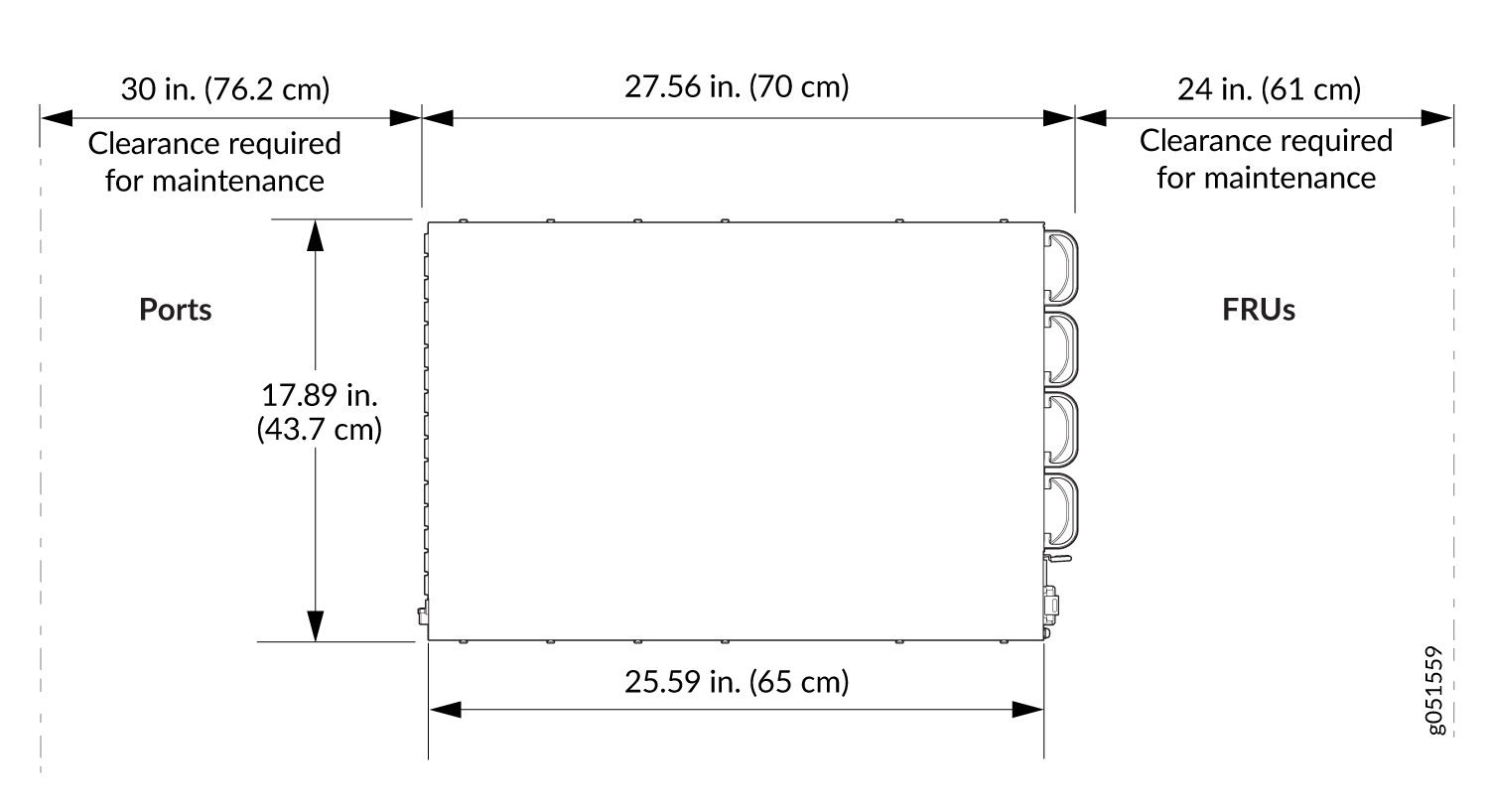

QFX5241-64OD and QFX5241-64QD Clearance Requirements for Airflow and Hardware Maintenance

When planning the site for installing the QFX5241-64OD and QFX5241-64QD switches, you must allow sufficient clearance around the installed chassis (see Figure 2).

-

For the cooling system to function properly, the airflow around the chassis must be unrestricted. See QFX5241-64OD and QFX5241-64QD Cooling System for more information about the airflow through the chassis.

-

If you are mounting the QFX5241-64OD and QFX5241-64QD switches in a rack with other equipment, ensure that the exhaust from other equipments does not blow into the intake vents of the chassis.

-

To facilitate service personnel movement, provision space of at least 24 in. (61 cm) both in the front and back of the switch. For compliance with NEBS GR-63 standards, leave 30 in. (76.2 cm) of space in front of the rack and 24 in. (61 cm) of space behind the rack.

Site Electrical Wiring Guidelines

Table 2 describes the factors you must consider while planning the electrical wiring at your site.

You must provide a properly grounded and shielded environment and use electrical surge-suppression devices.

Avertissement Vous devez établir un environnement protégé et convenablement mis à la terre et utiliser des dispositifs de parasurtension.

|

Site Wiring Factor |

Guidelines |

|---|---|

|

Signaling limitations |

If your site experiences any of the following problems, consult experts in electrical surge suppression and shielding:

|

|

Radio frequency interference |

To reduce or eliminate RFI from your site wiring, do the following:

|

|

Electromagnetic compatibility |

If your site is susceptible to problems with electromagnetic compatibility (EMC), particularly from lightning or radio transmitters, seek expert advice. Strong sources of electromagnetic interference (EMI) can cause:

|

QFX5241-64OD and QFX5241-64QD Rack Requirements

You can install or mount the AC and DC variants of QFX5241-64OD and QFX5241-64QD switches on a four-post rack using the QFX5240-2U-4PRMK toolless rack mount kit.

Rack requirements for installation using the QFX5240-2U-4PRMK consists of:

-

Rack type

-

Mounting bracket hole spacing

-

Rack size and strength

|

Rack Requirement |

Guidelines |

|---|---|

|

Rack type |

Use a four-post rack that provides bracket holes or hole patterns spaced at 1-U (1.75 in. or 4.45 cm) increments. The rack must meet the size and strength requirements to support the weight. A U is the standard rack unit defined in Cabinets, Racks, Panels, and Associated Equipment (document number EIA-310–D) published by the Electronics Industry Association. |

|

Mounting bracket hole spacing |

The holes in the mounting brackets are spaced at 1-U (1.75 in. or 4.45 cm) increments, so that the switch can be mounted in any four-post rack that provides holes spaced at that distance. |

|

Rack size and strength |

|

|

Rack connection to building structure |

|