ON THIS PAGE

Maintaining QFX10000 Power System

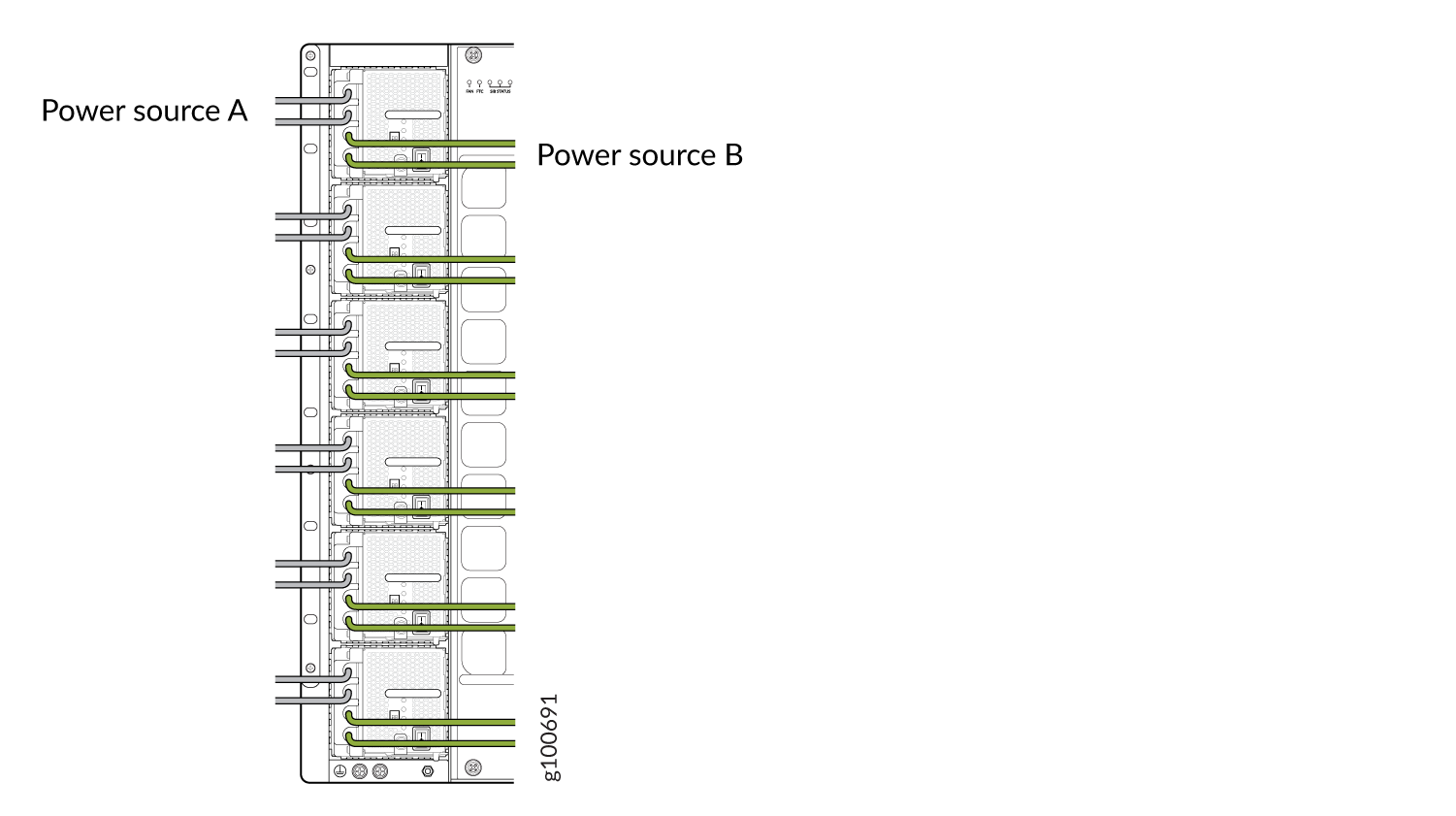

QFX10008 and QFX10016 routers support both AC and DC power supplies. Additionally, QFX10000 routers support high voltage alternating current (HVAC) or high voltage direct current (HVDC) power supplies. To install and remove the power supplies in a QFX10008 router or a QFX10016 router, refer to the following sections.

How to Remove a QFX10000-PWR-AC Power Supply

Before you remove a power supply from the chassis:

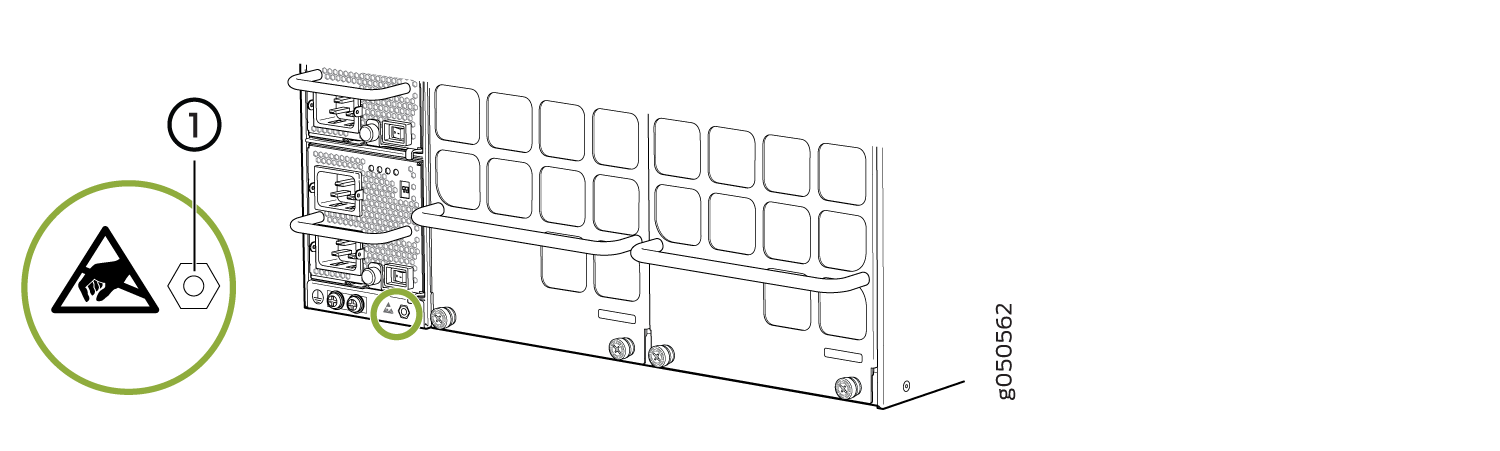

Ensure you understand how to prevent ESD damage. See Prevention of Electrostatic Discharge Damage.

Ensure that you have the following parts and tools available to remove an QFX10000-PWR-AC power supply from a QFX10000 switch:

Electrostatic discharge (ESD) grounding strap

Phillips (+) screwdriver, number 1

Replacement power supply or a cover for the power supply slot

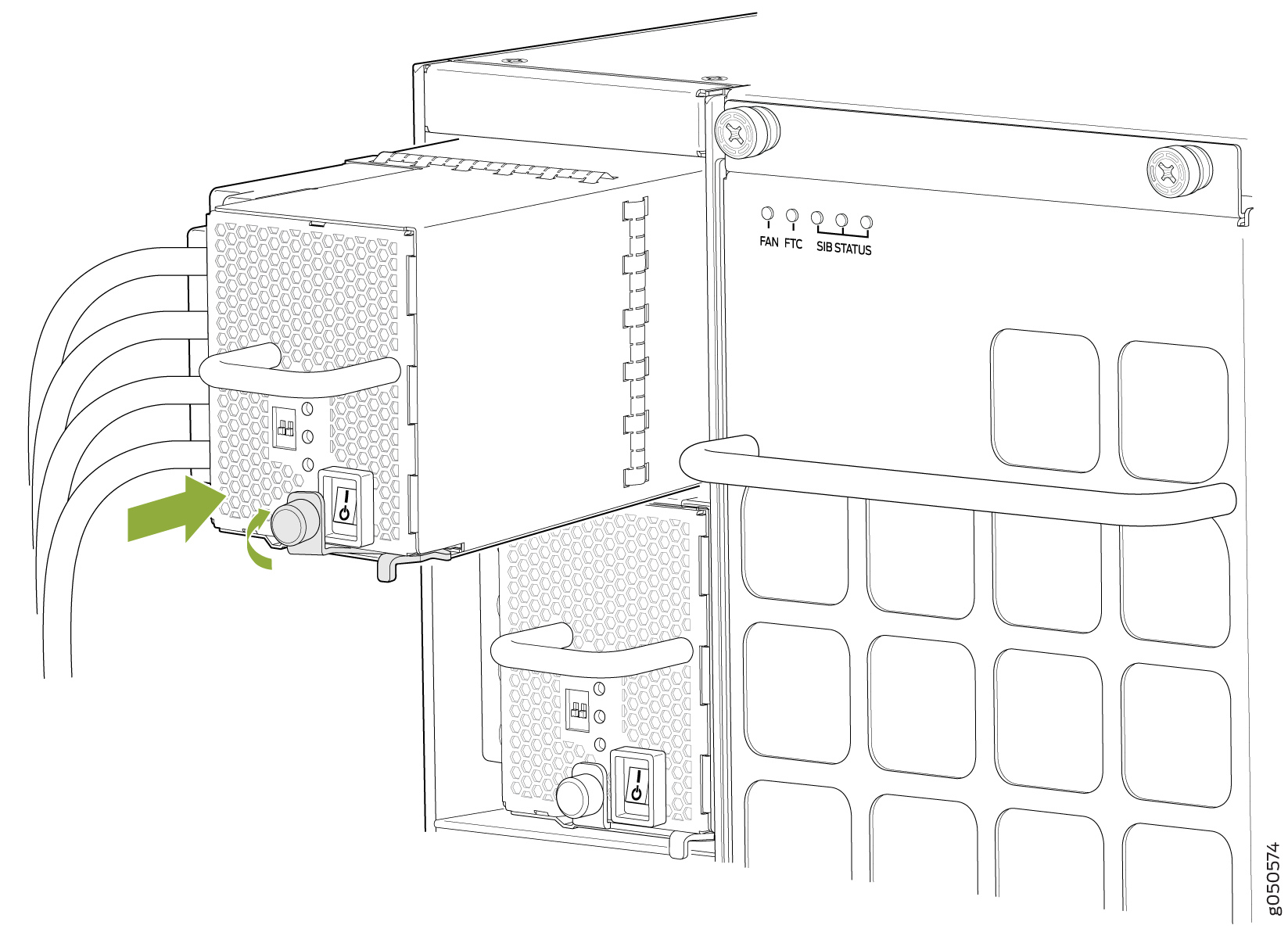

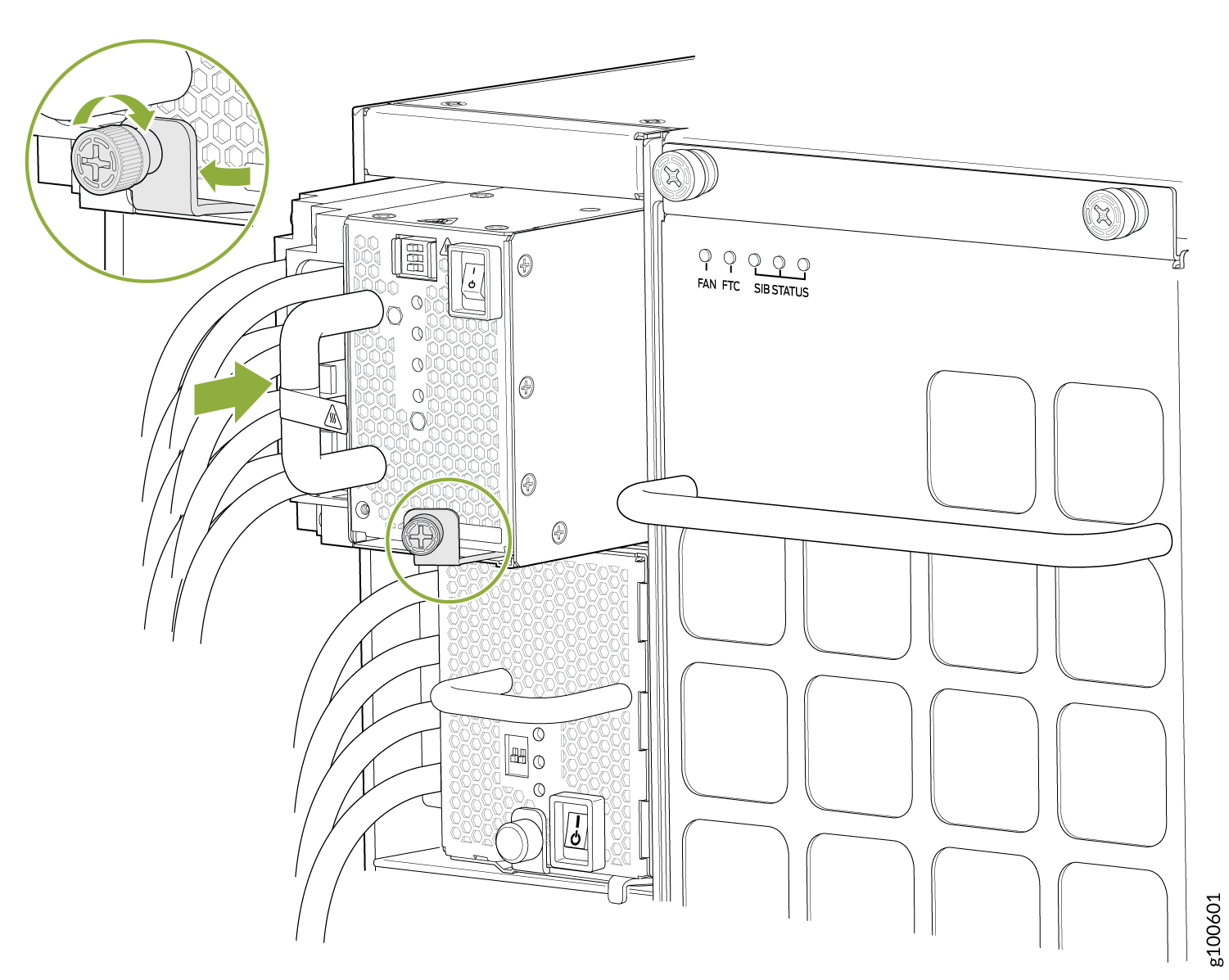

The QFX10000-PWR-AC power supply in a QFX10008 and QFX10016 switch chassis is a hot-removable and hot-insertable field-replaceable unit (FRU). You remove all power supplies from the rear of the chassis.

Before you remove a power supply, ensure that you have power supplies sufficient to power the switch left in the chassis. See Power Requirements for QFX10000 Components.

Do not leave the power supply slot empty for a long time while the switch is operational. Either replace the power supply promptly or install a cover over the empty slot.

To remove a QFX10000-PWR-AC power supply from a QFX10000 switch:

How to Install a QFX10000-PWR-AC Power Supply

Before you install an QFX10000-PWR-AC power supply in the switch:

Ensure you understand how to prevent ESD damage. See Prevention of Electrostatic Discharge Damage.

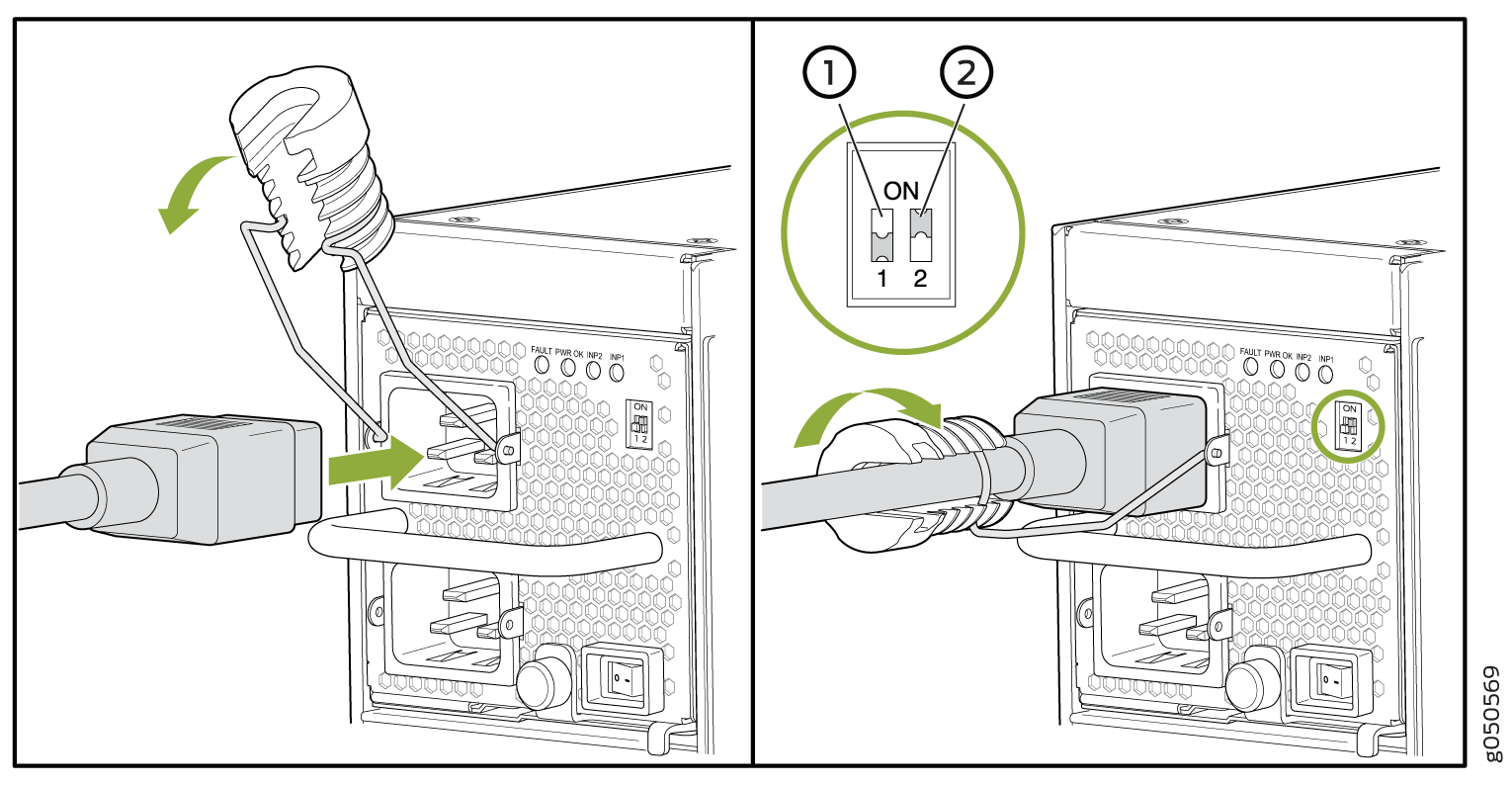

If the AC power source outlets have a power switch, set them to the off (O) position.

Ensure that you have the following parts and tools available to install a QFX10000-PWR-AC power supply:

Electrostatic discharge (ESD) grounding strap

Phillips (+) screwdriver, number 1

Power cords appropriate for your geographical location. See QFX10000 Power Cables Specifications.

Power cord retainer clips

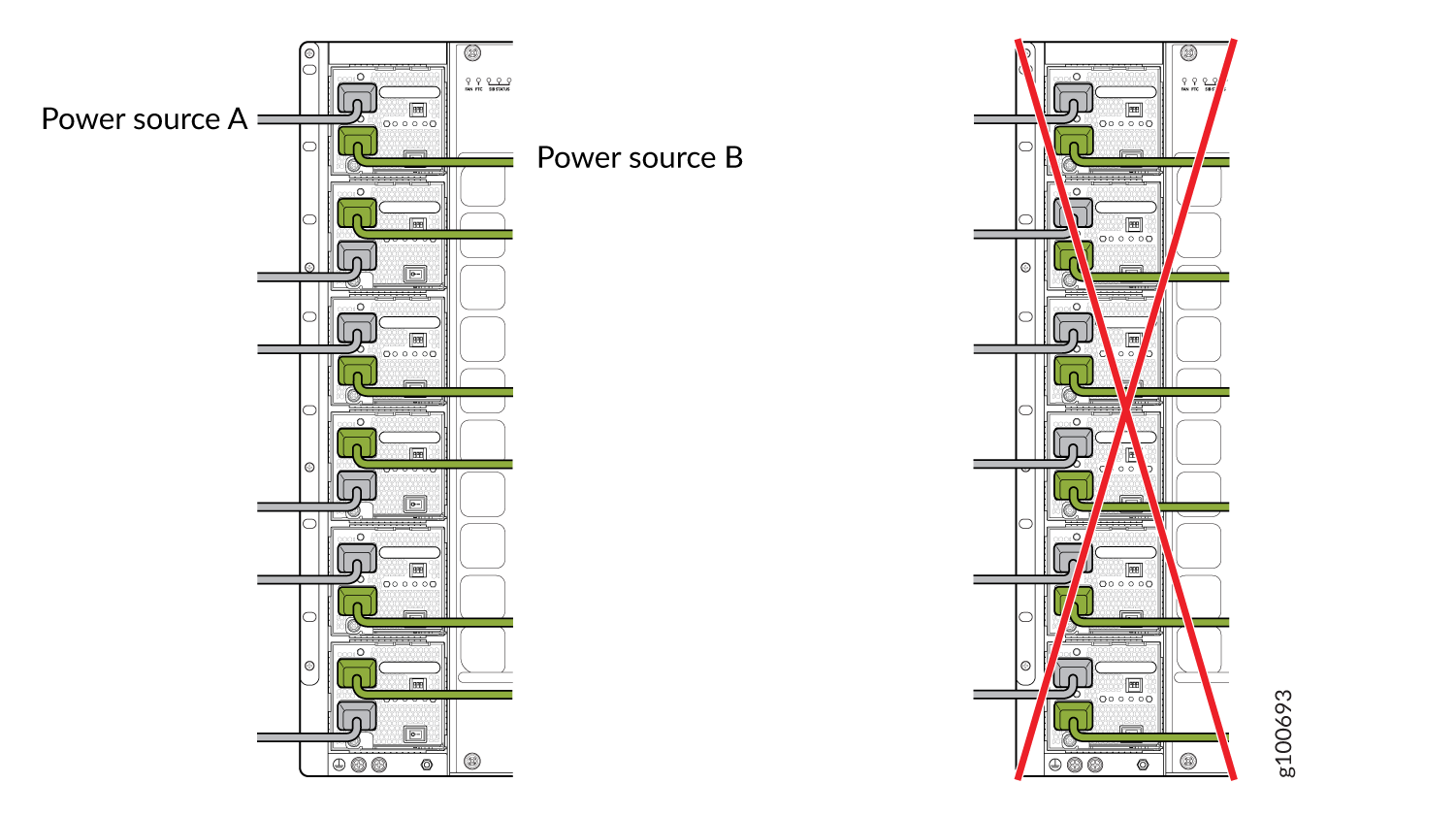

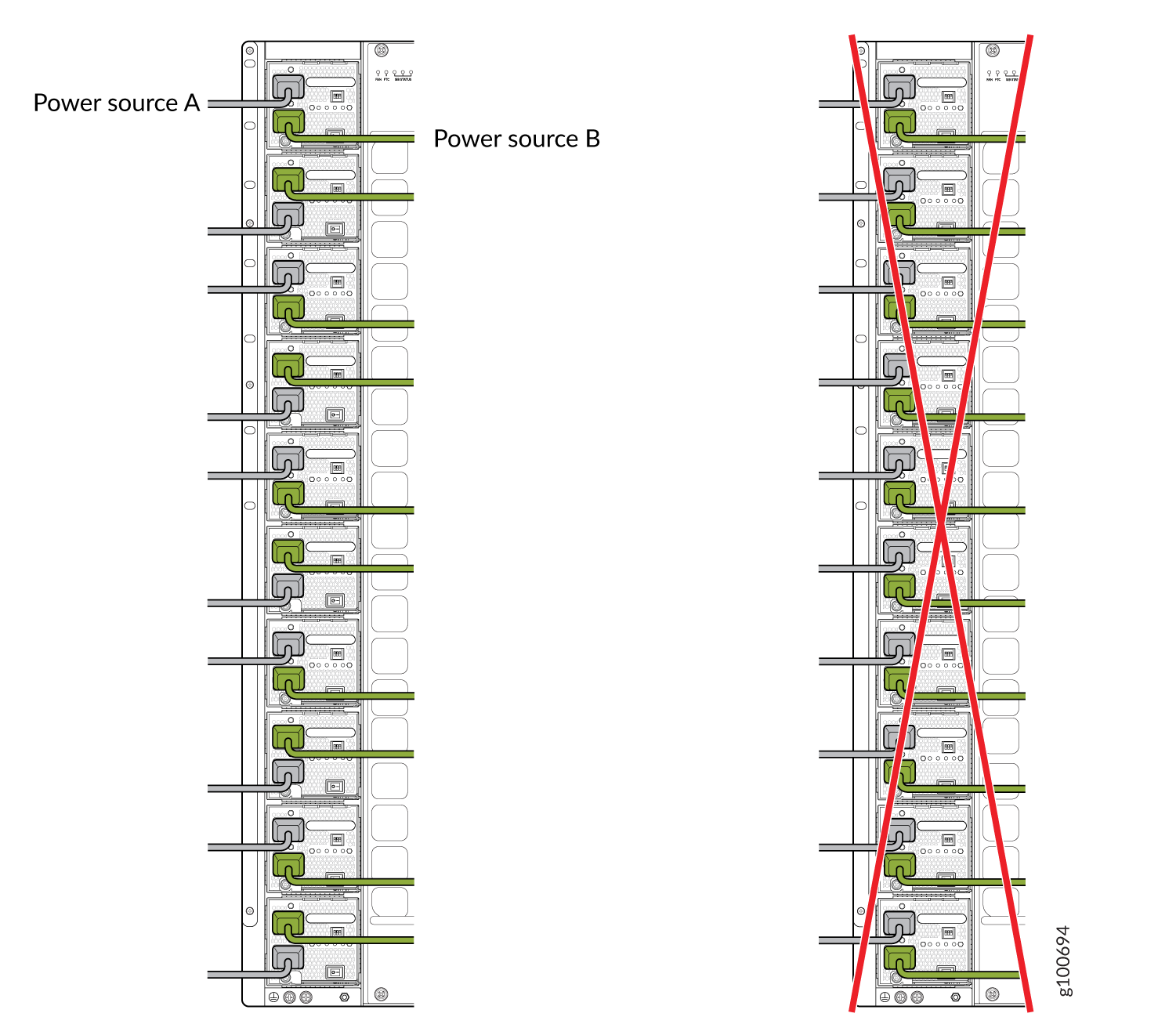

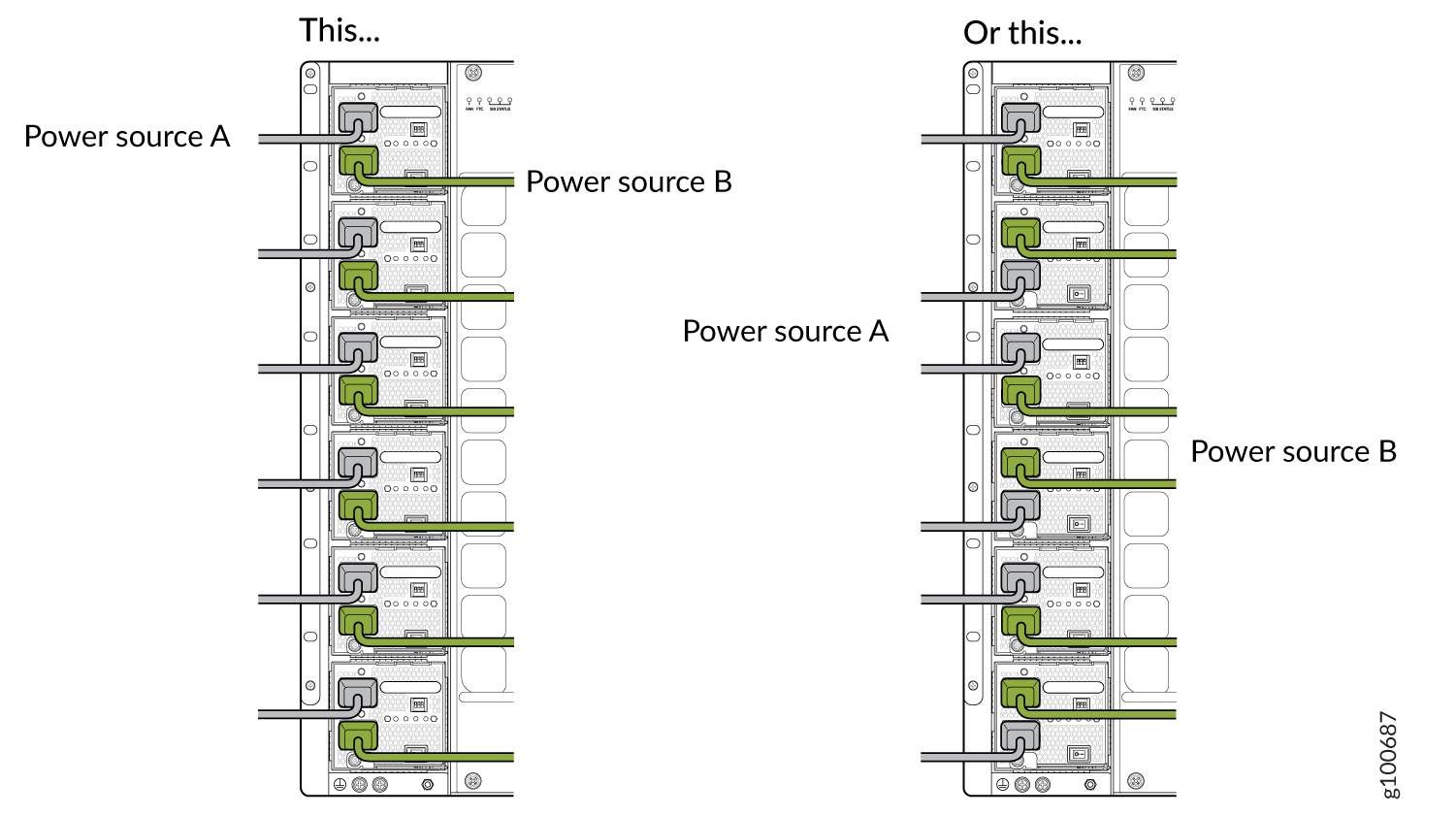

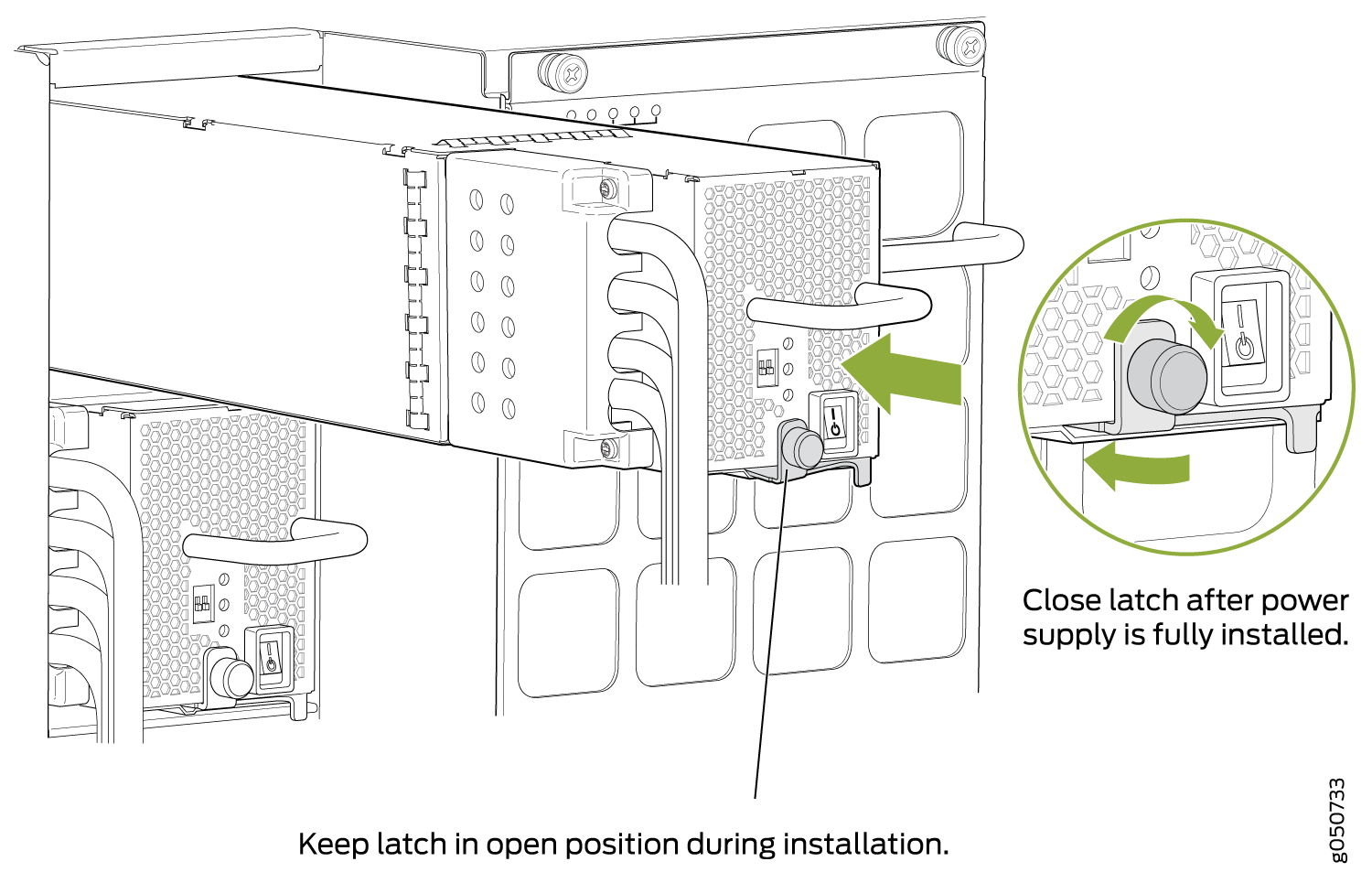

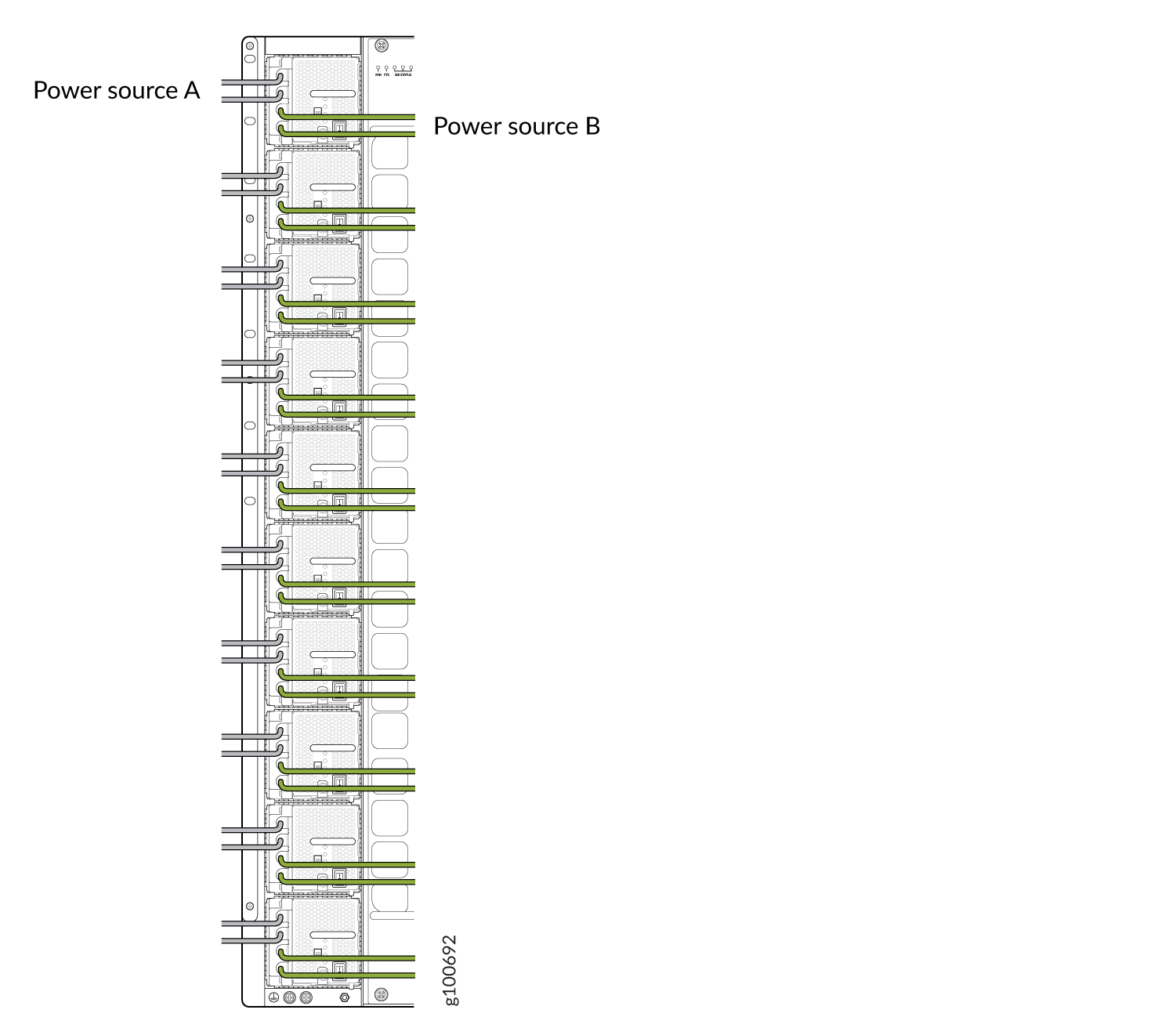

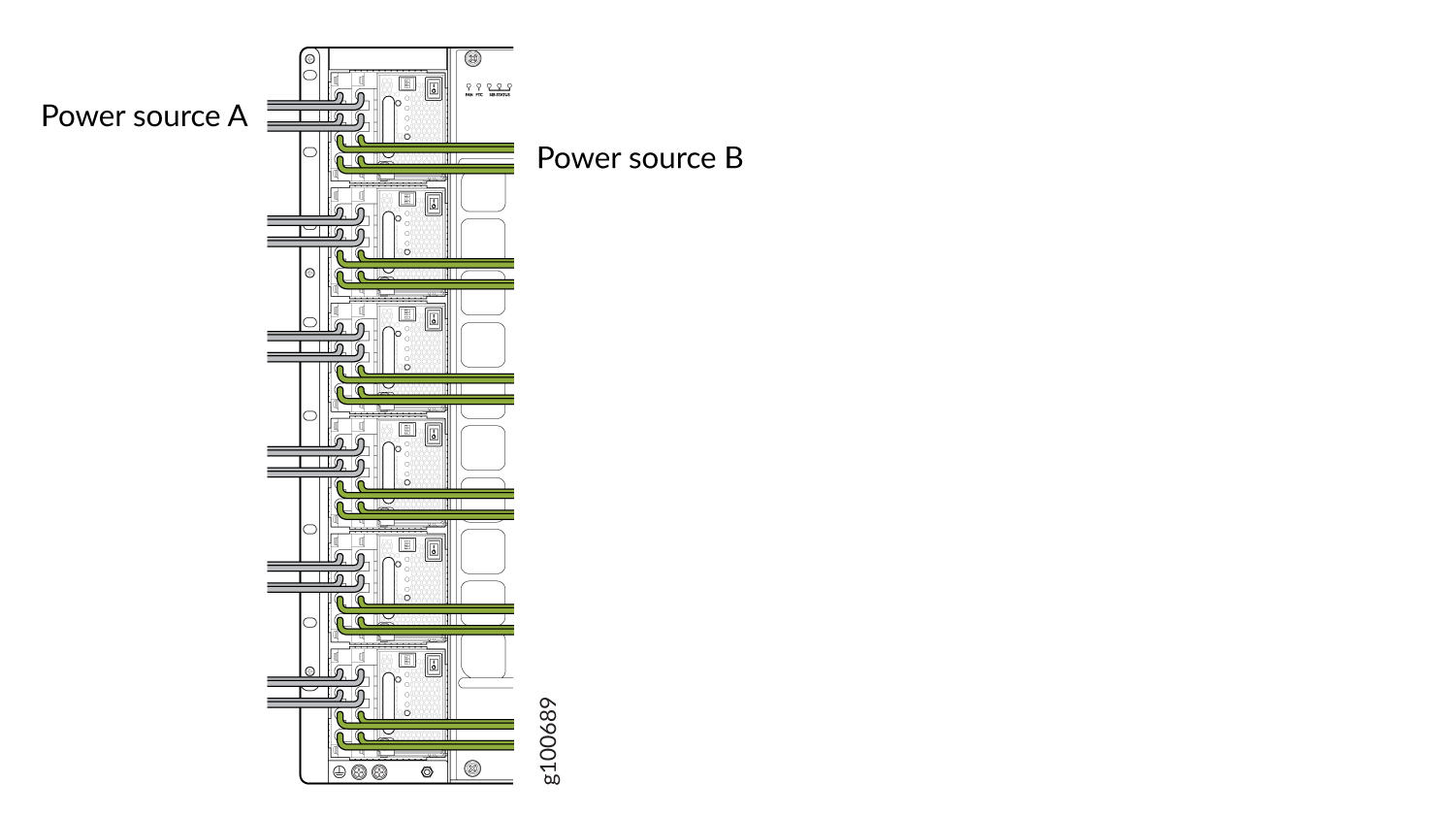

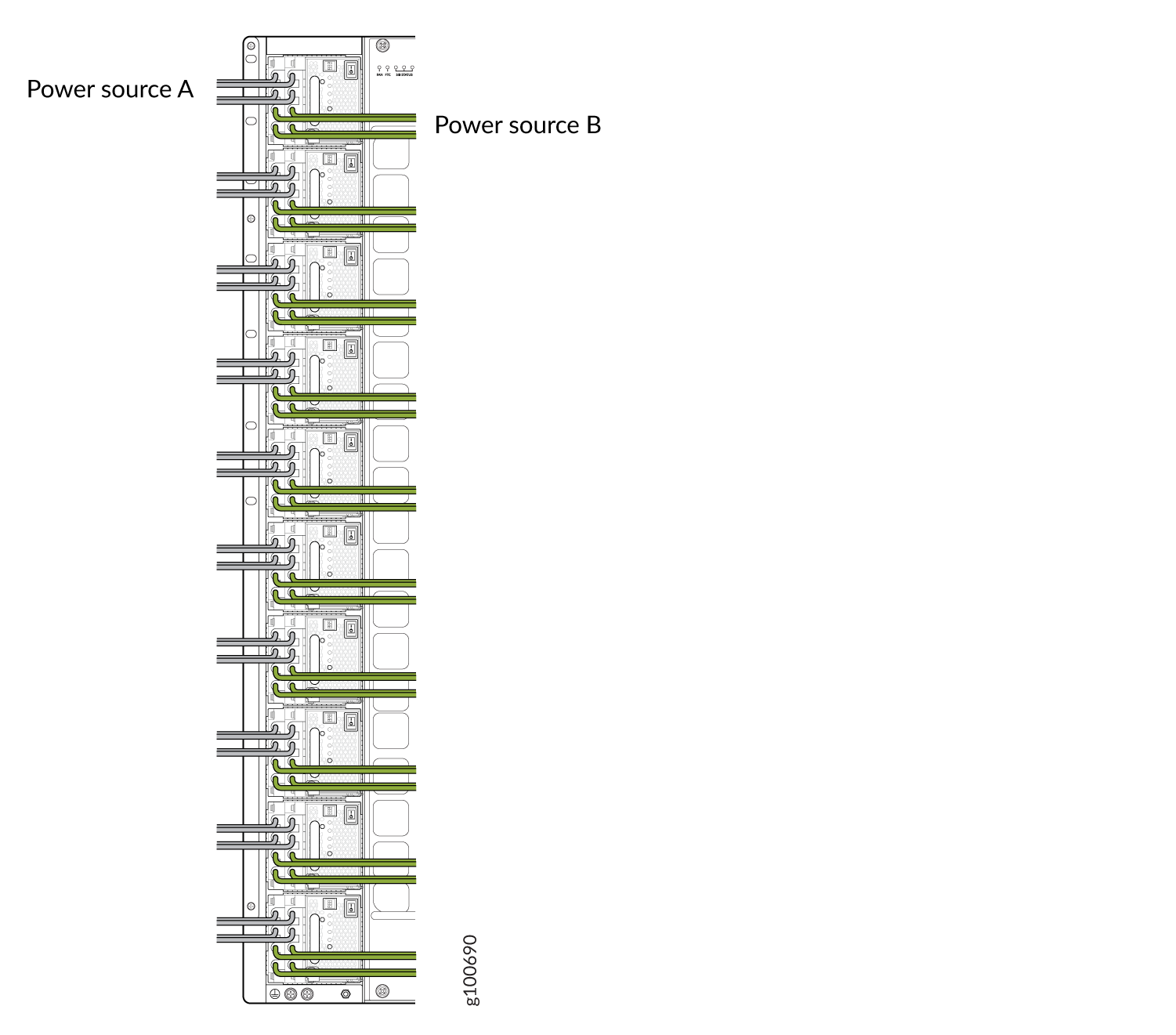

The QFX10000-PWR-AC power supply is a hot-insertable and hot-removable field-replaceable unit (FRU). You can install up to 6 QFX10000-PWR-AC power supplies in a QFX10008 and 10 in a QFX10016 switch chassis. All power supplies install in the rear of the chassis in the slots provided along the left side.

Do not mix AC and DC power supplies in the same chassis.

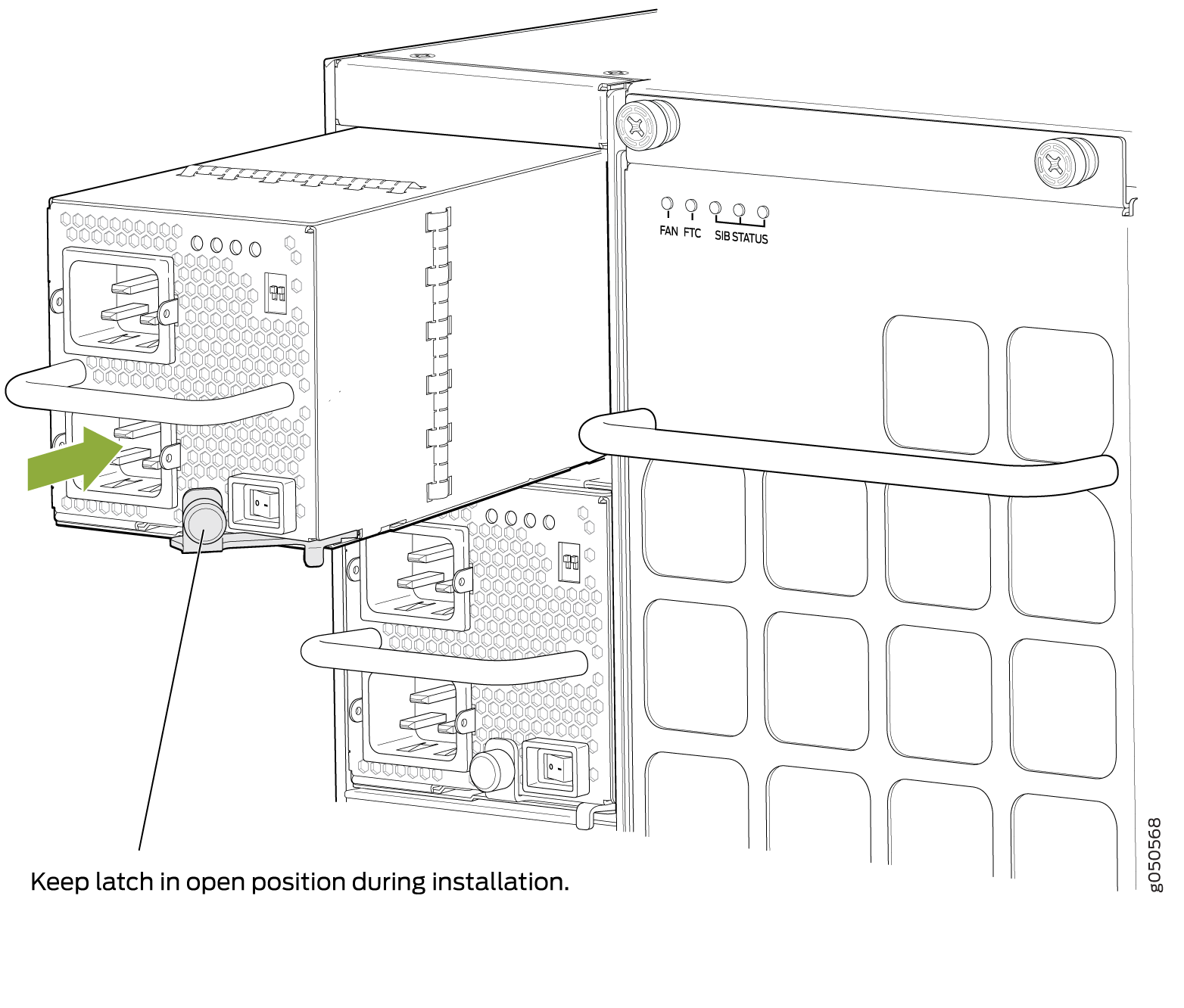

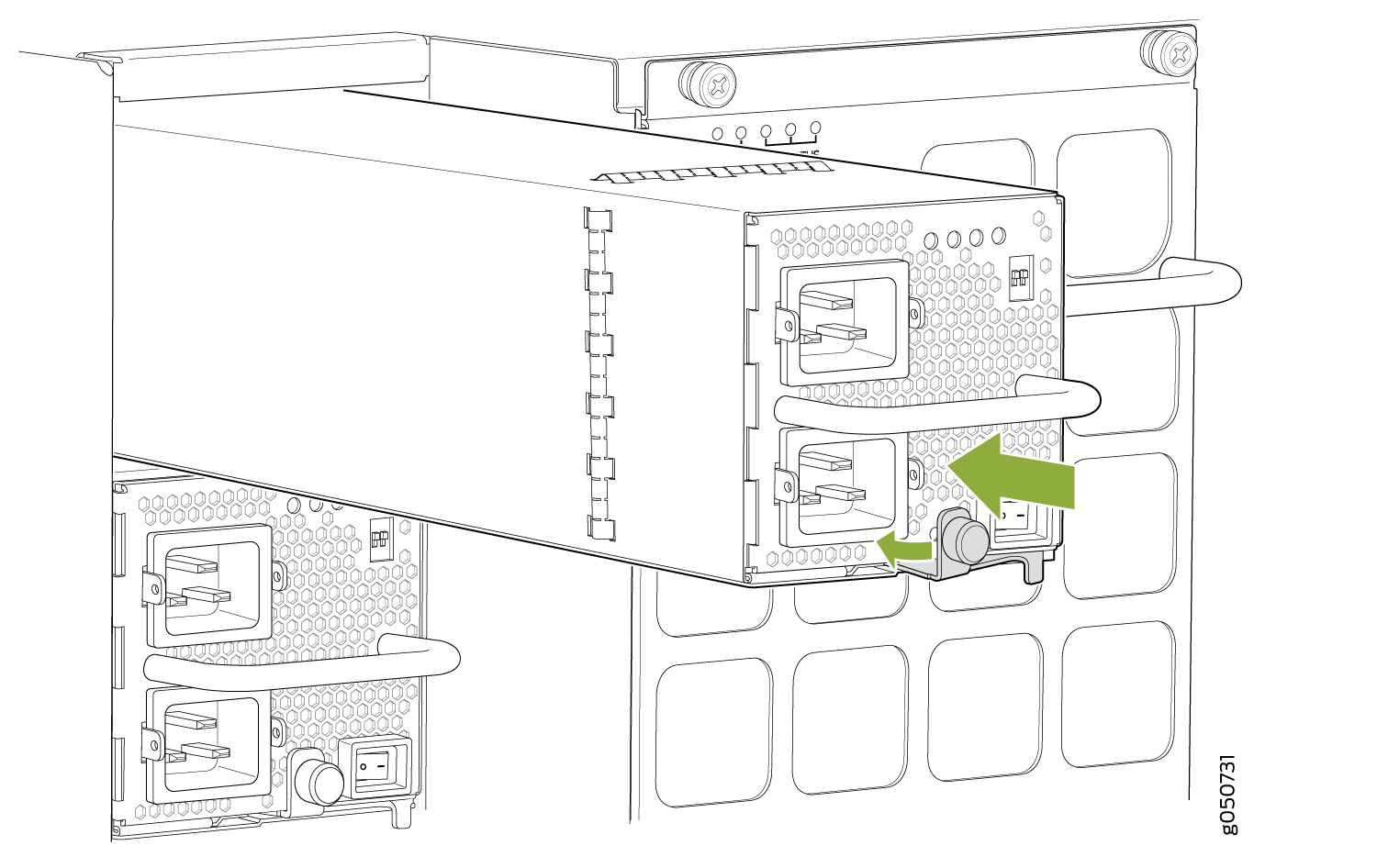

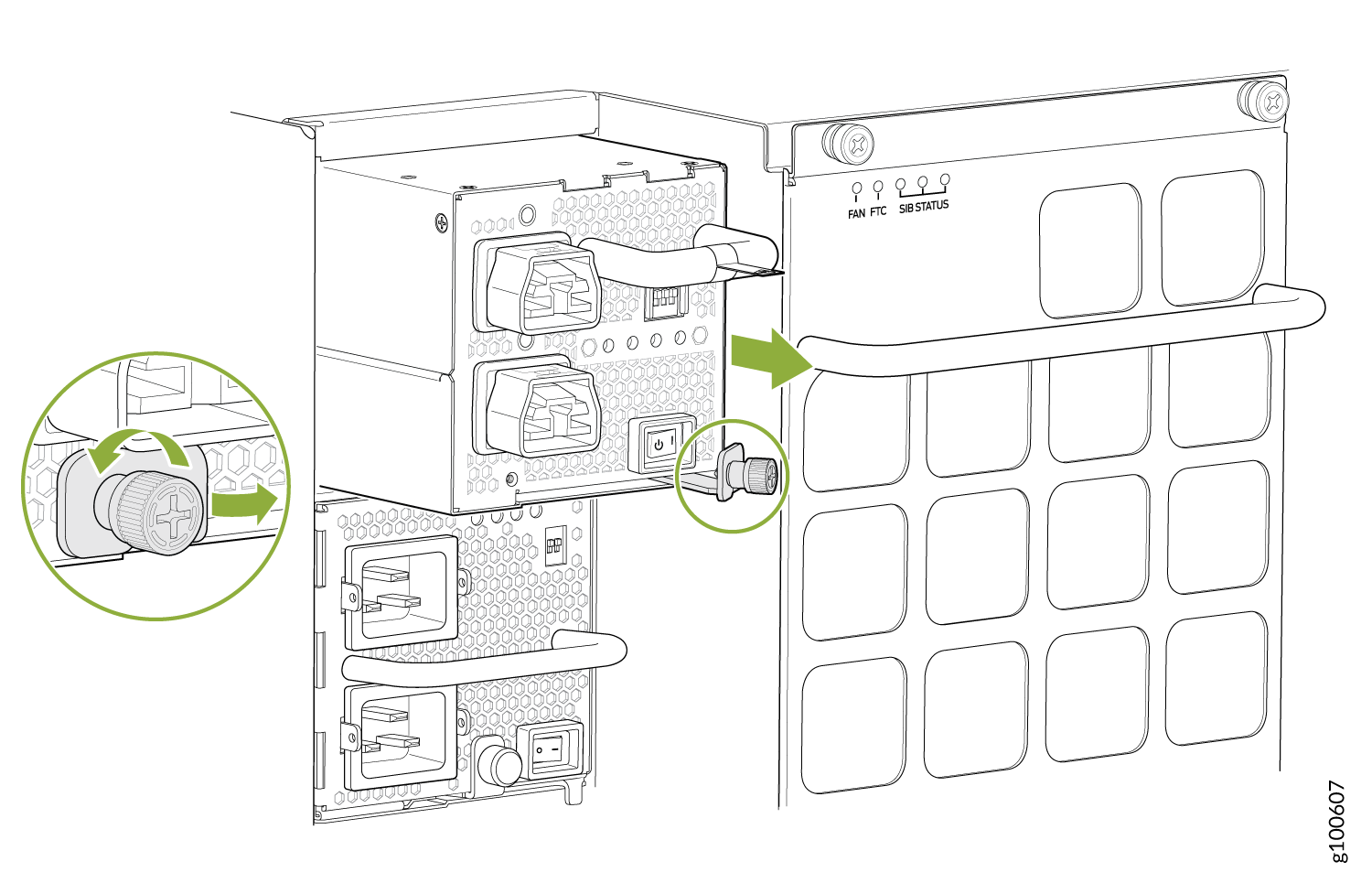

To install a QFX10000-PWR-AC power supply in a QFX10008 or QFX10016:

See Also

How to Remove a JNP10K-PWR-AC2 Power Supply

Before you remove an JNP10K-PWR-AC2 power supply from the chassis:

Ensure you understand how to prevent ESD damage. See Prevention of Electrostatic Discharge Damage.

Ensure that you have the following parts and tools available to remove a JNP10K-PWR-AC2 power supply from a QFX10000 switch:

Heat protective gloves able to withstand temperatures in the range of 158°F (70°C) to 176°F (80°C)

Electrostatic discharge (ESD) grounding strap

Phillips (+) screwdriver, number 1

Replacement power supply or a cover panel for the power supply slot

The JNP10K-PWR-AC2 power supply in a QFX10008 or a QFX10016 chassis is a hot-removable and hot-insertable field-replaceable unit (FRU). You remove all power supplies from the rear of the chassis.

Protect yourself from severe burns by wearing heat-protective gloves when removing a working QFX10000-PWR-AC2 power supply from the chassis. These power supplies can reach in the range of 158°F (70°C) to 176°F (80°C).

Before you remove a power supply, ensure that you have power supplies sufficient to power the switch left in the chassis. See Power Requirements for QFX10000 Components.

Do not leave the power supply slot empty for a long time while the switch is operational. Either replace the power supply promptly or install a cover panel over the empty slot.

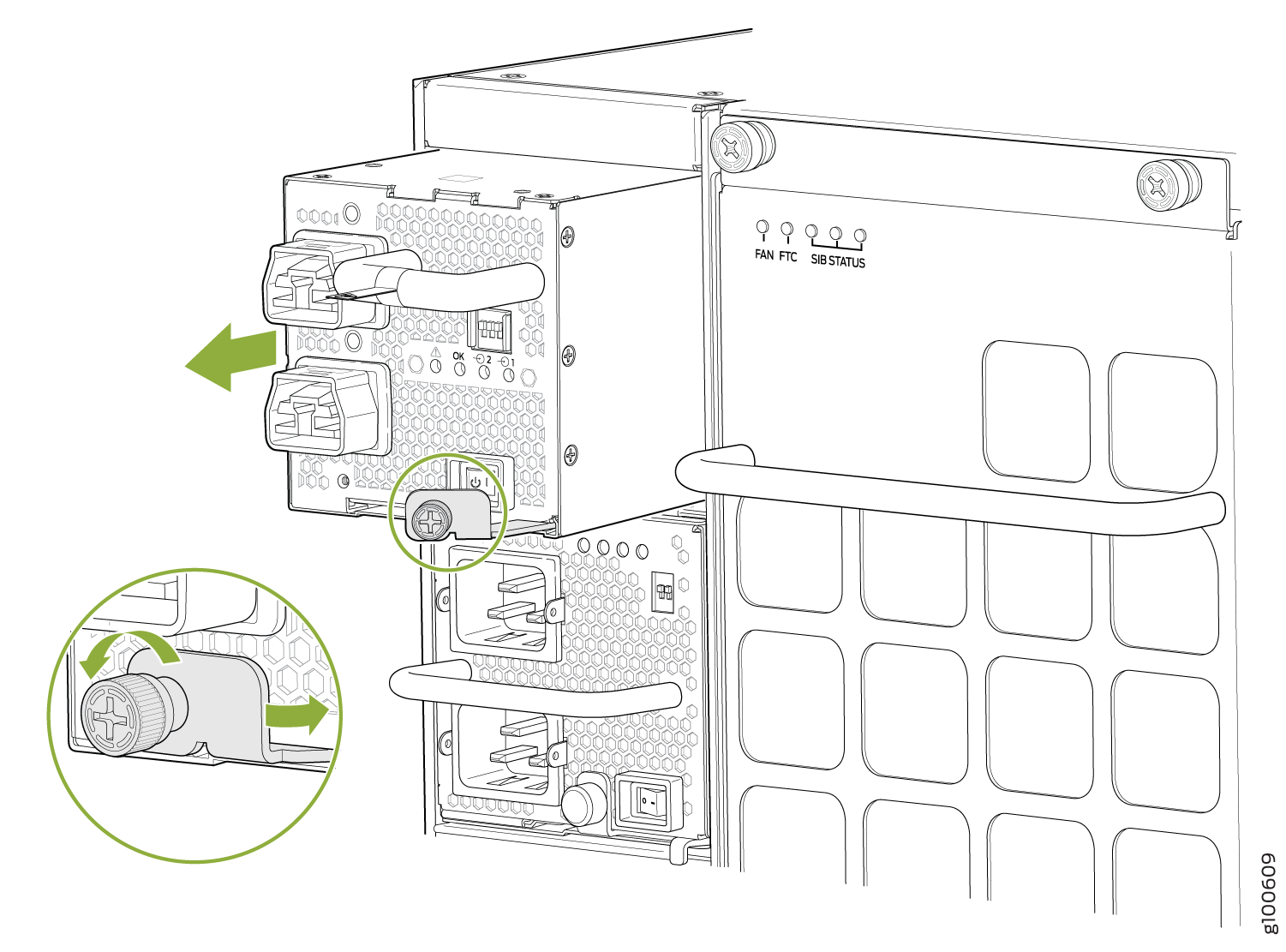

To remove a JNP10K-PWR-AC2 power supply from a QFX10000 switch:

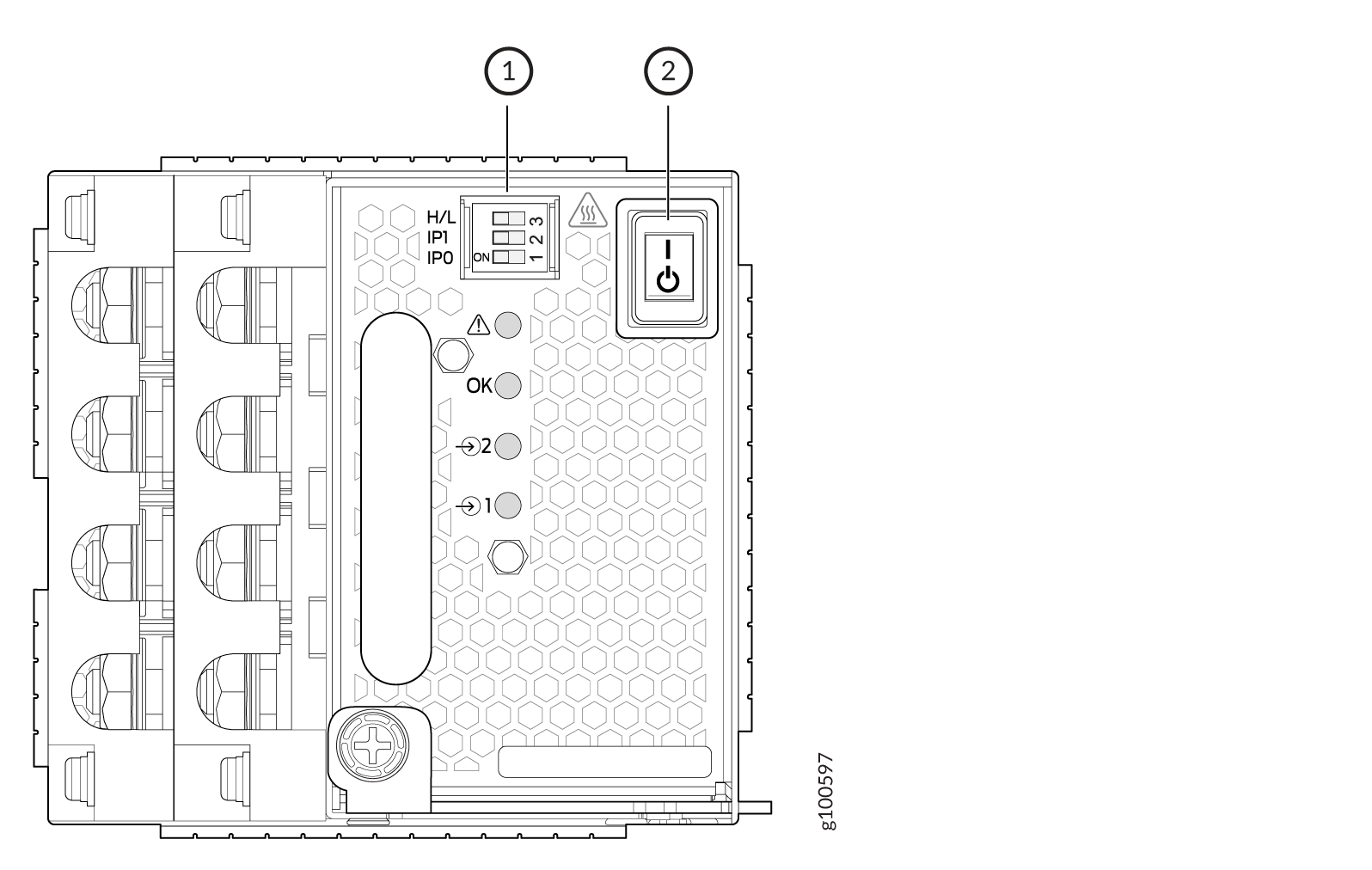

How to Install a JNP10K-PWR-AC2 Power Supply

The JNP10K-PWR-AC2 power supply in a QFX10008 or a QFX10016 chassis is a hot-insertable and hot-removable field-replaceable unit (FRU). You can install up to 6 JNP10K-PWR-AC2 power supplies in a QFX10008 and 10 in a QFX10016 switch chassis. All power supplies install in the rear of the chassis in the slots provided along the left side.

Do not mix AC and DC power supplies in the same running chassis. You may have both QFX10000-PWR-AC and JNP10K-PWR-AC2 in the same chassis while swapping out one type of power supply for the other.

Protect yourself from severe burns by wearing heat-protective gloves when removing a running JNP10K-PWR-AC2 power supply from the chassis. The power supply can reach in the range of 158°F (70°C) to 176°F (80°C).

Before you install a JNP10K-PWR-AC2 power supply in the chassis:

Ensure that you have followed all safety warnings and cautions:

Ensure you understand how to prevent ESD damage. See Prevention of Electrostatic Discharge Damage.

If the AC or DC power source outlets have a power switch, set them to the off (O) position.

Ensure that you have the following parts and tools available to install an JNP10K-PWR-AC2 power supply:

Electrostatic discharge (ESD) grounding strap

Phillips (+) screwdriver, number 1

Power cables appropriate for your geographical location (for low voltage installations) or input amperage (for high voltage installations). See QFX10000 Power Cables Specifications. HVAC and HVDC connectors and lugs must be installed by a qualified electrician before installation.

To install a JNP10K-PWR-AC2 power supply in a QFX10008 or a QFX10016:

How to Remove a QFX10000-PWR-DC Power Supply

Before you remove a DC power supply from the switch:

Ensure you understand how to prevent ESD damage. See Prevention of Electrostatic Discharge Damage.

Ensure that you have the following parts and tools available to remove a QFX10000-PWR-DC power supply:

Electrostatic discharge (ESD) grounding strap

Phillips (+) screwdriver, numbers 1 and 2

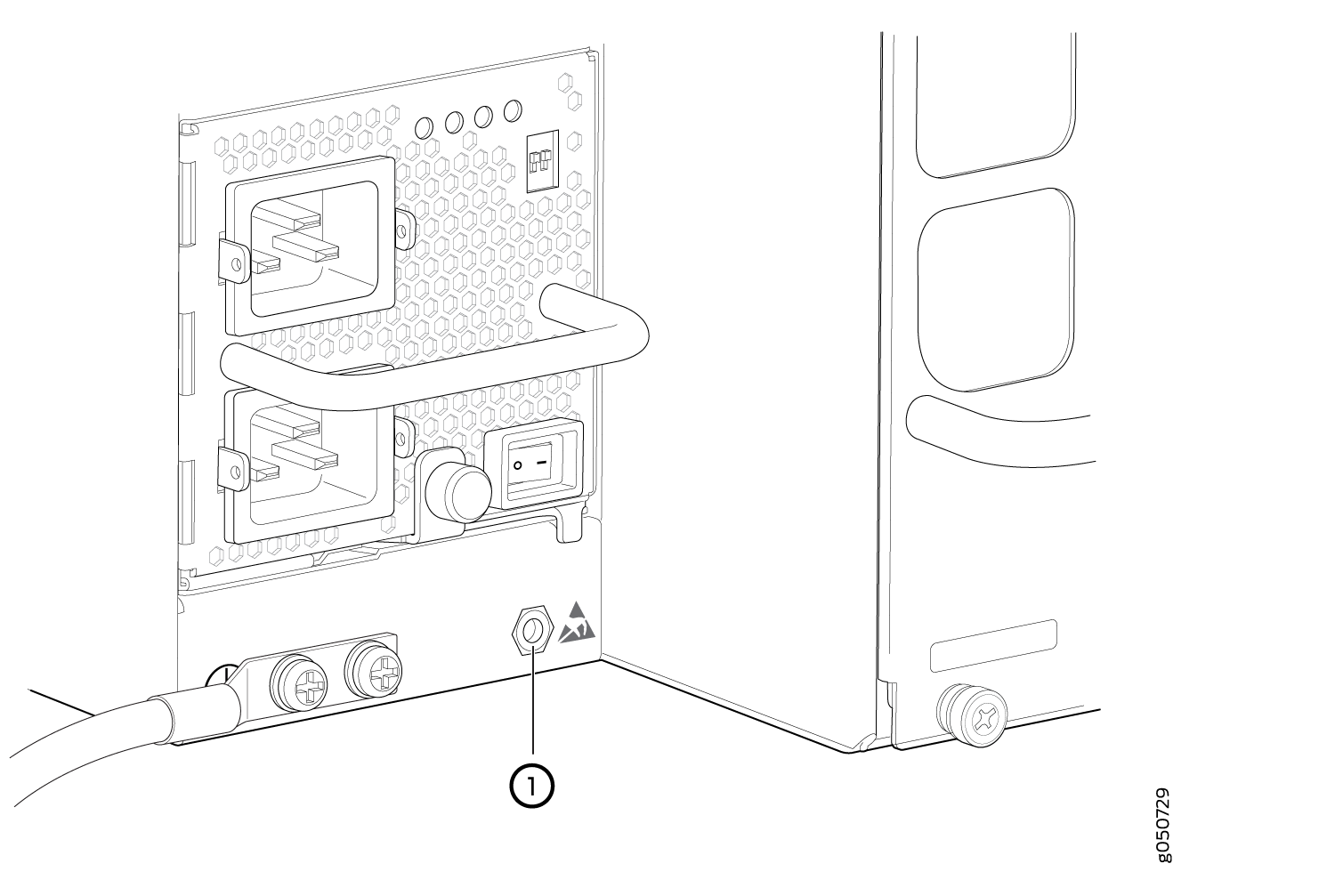

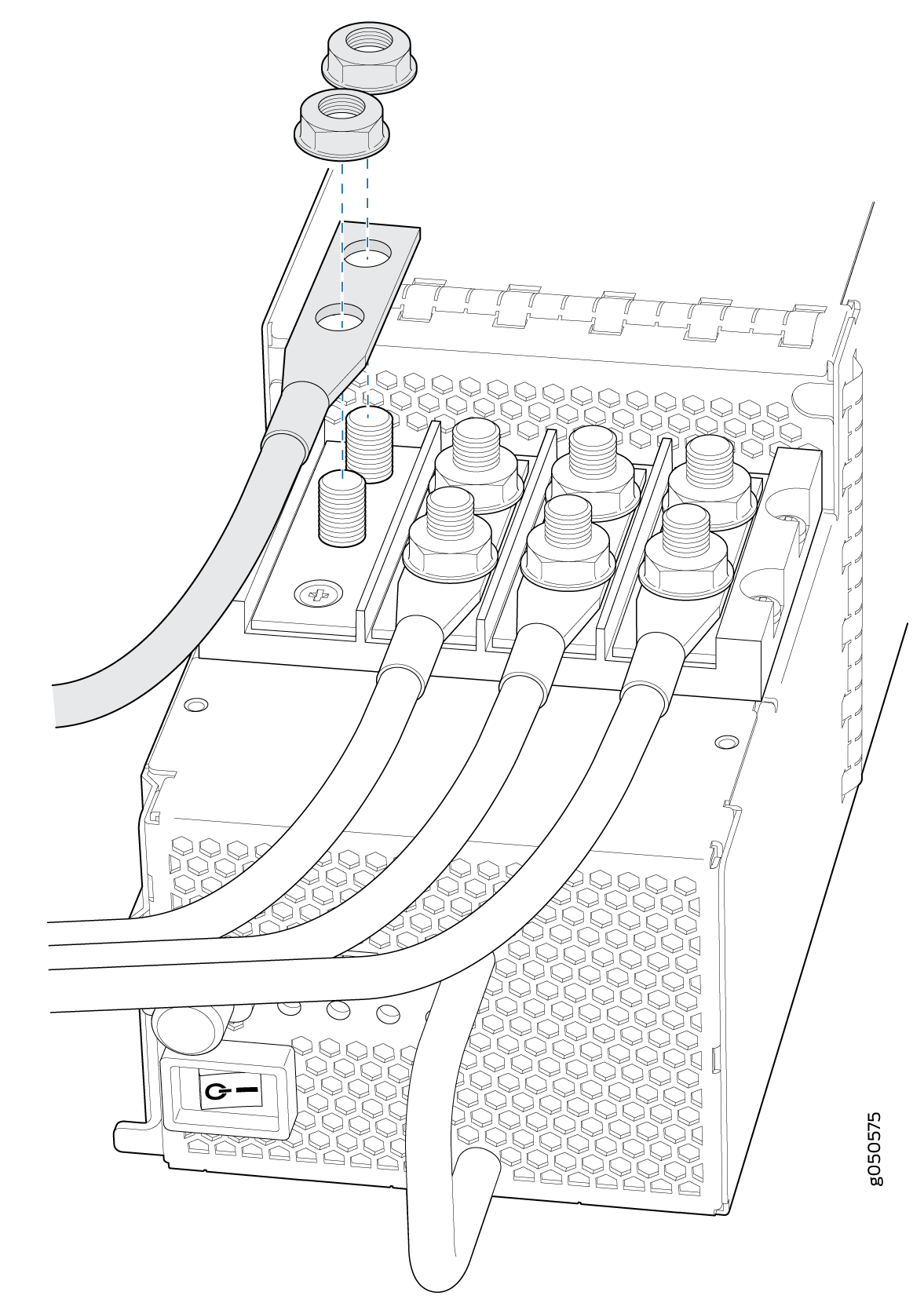

13/32 in. (10 mm) nut driver or socket wrench

Replacement power supply or a cover for the power supply slot

The QFX10000-PWR-DC power supply in a QFX10008 and QFX10016 chassis is a hot-removable and hot-insertable field-replaceable unit (FRU). You remove DC power supplies from the rear of the chassis.

Before you remove a power supply, ensure that you have power supplies sufficient to power the switch left in the chassis. See Power Requirements for QFX10000 Components.

Before performing DC power procedures, ensure that power is removed from the DC circuit. To ensure that all power is off, locate the circuit breaker on the panel board that services the DC circuit, switch the circuit breaker to the OFF position, and tape the switch handle of the circuit breaker in the OFF position.

Do not leave the power supply slot empty for a long time while the switch is operational. Either replace the power supply promptly or install a cover over the empty slot.

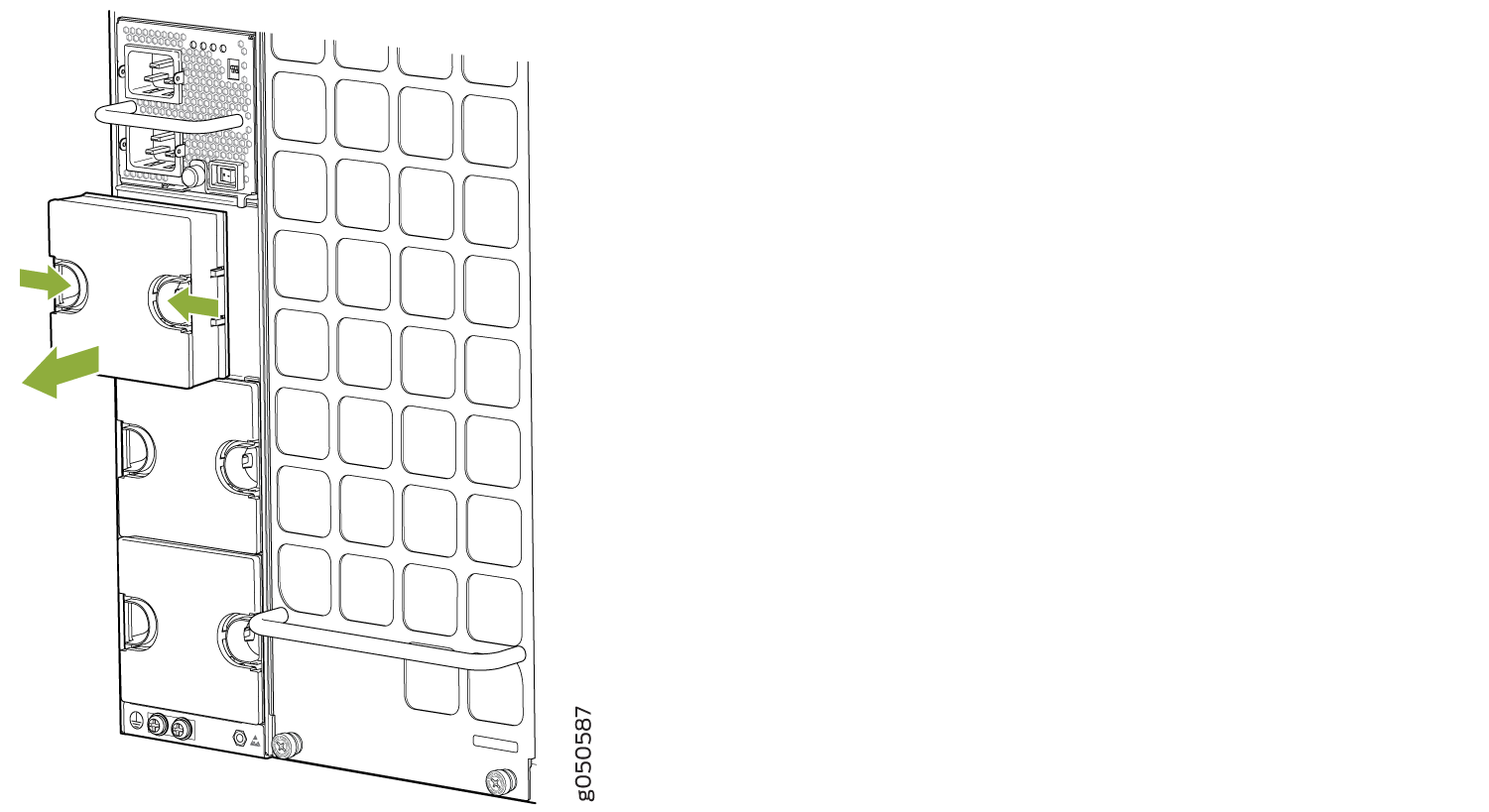

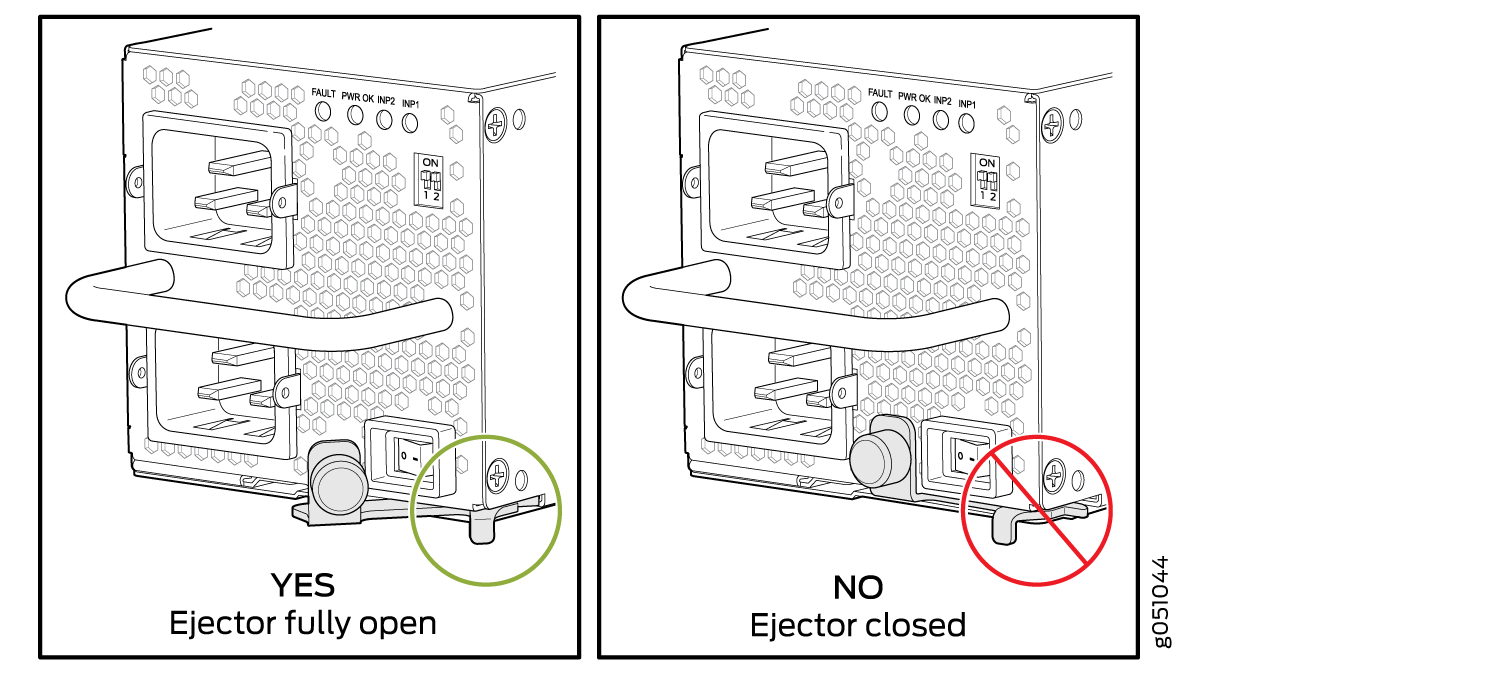

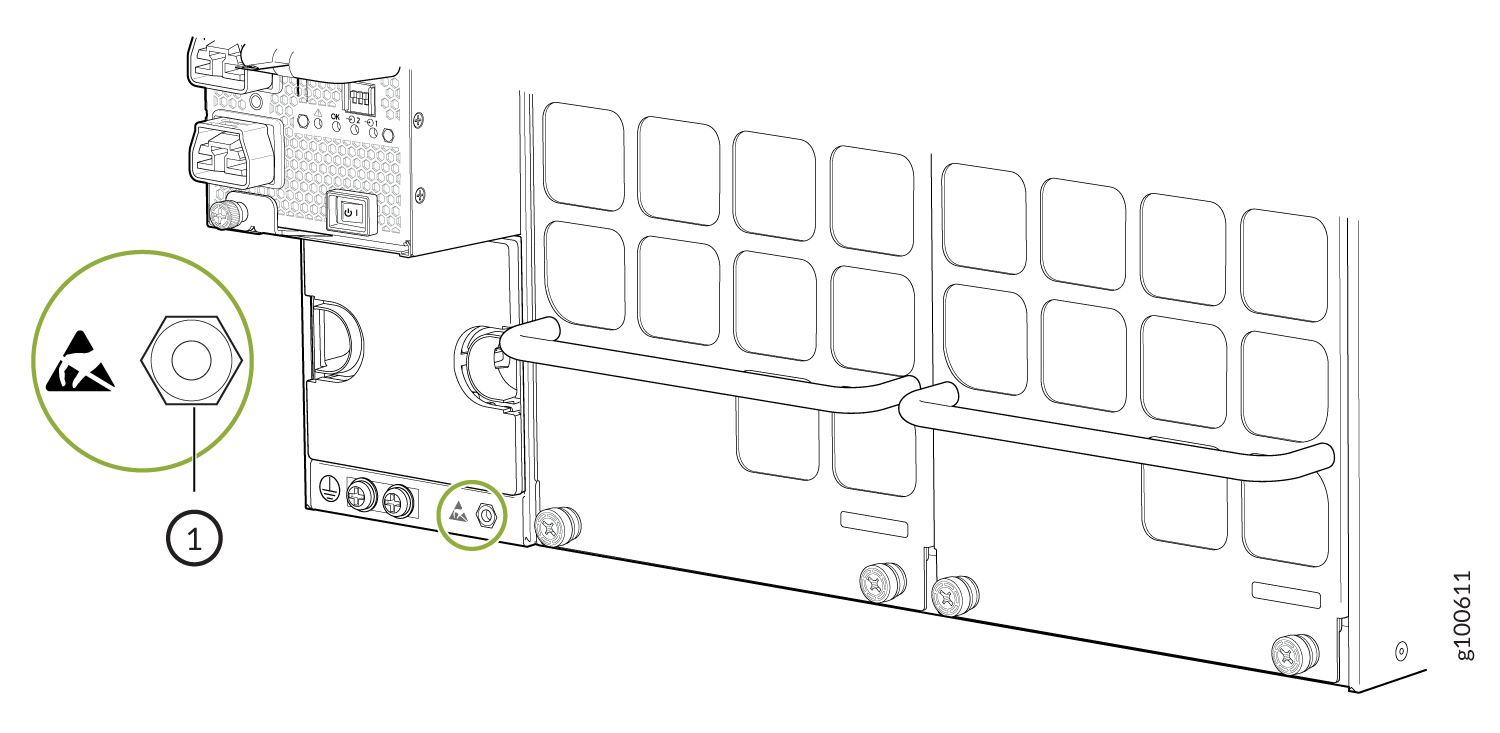

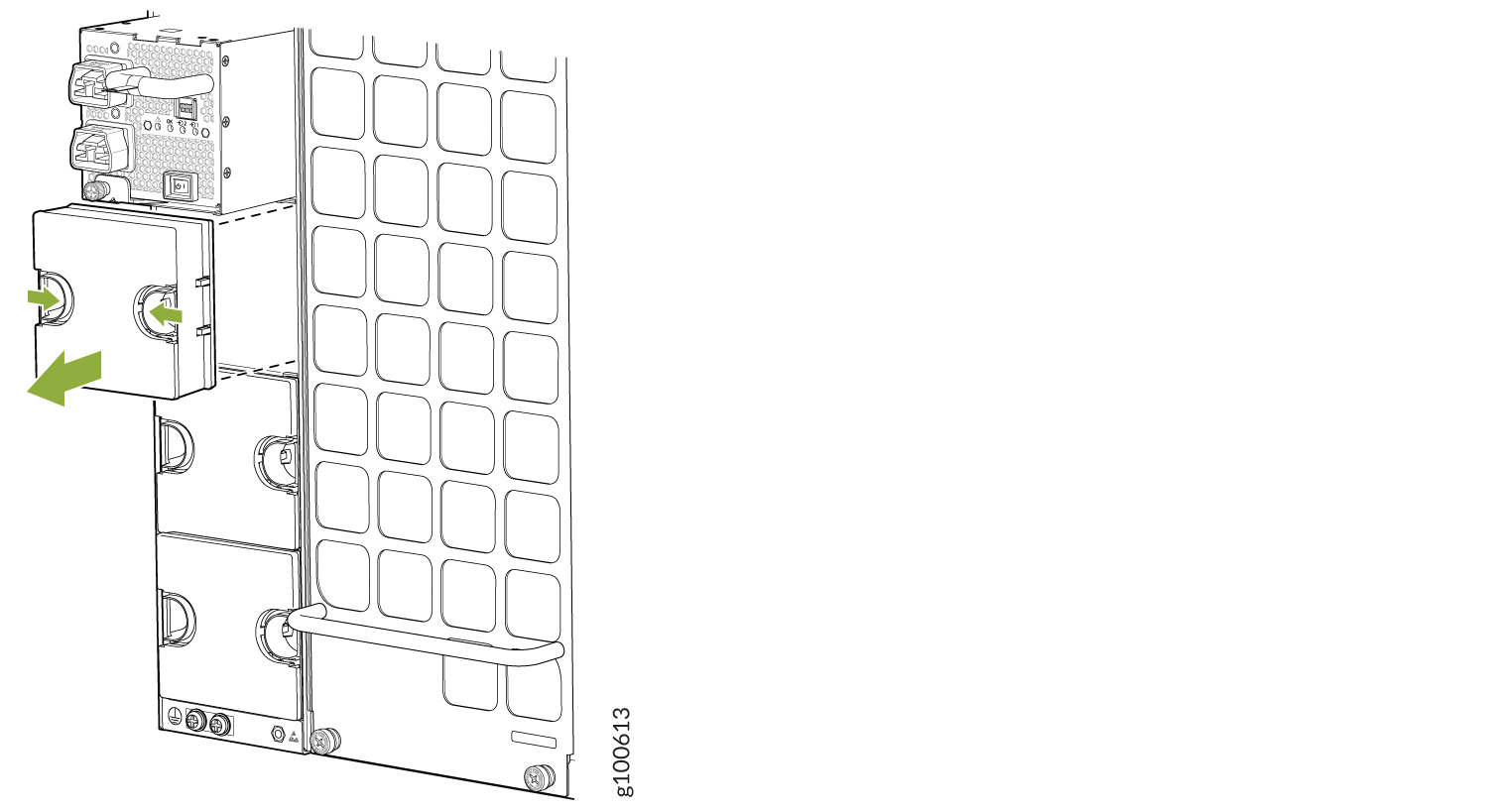

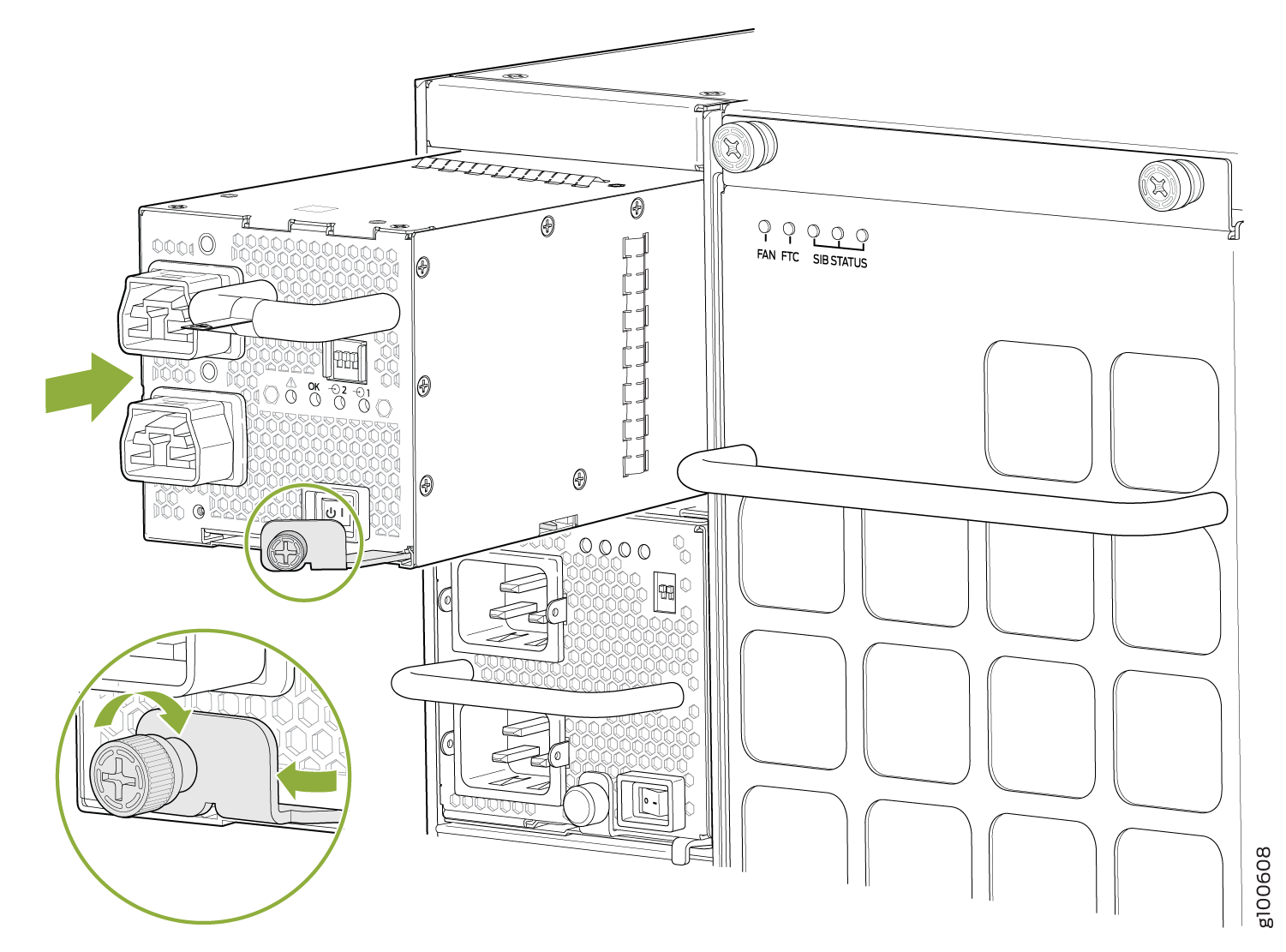

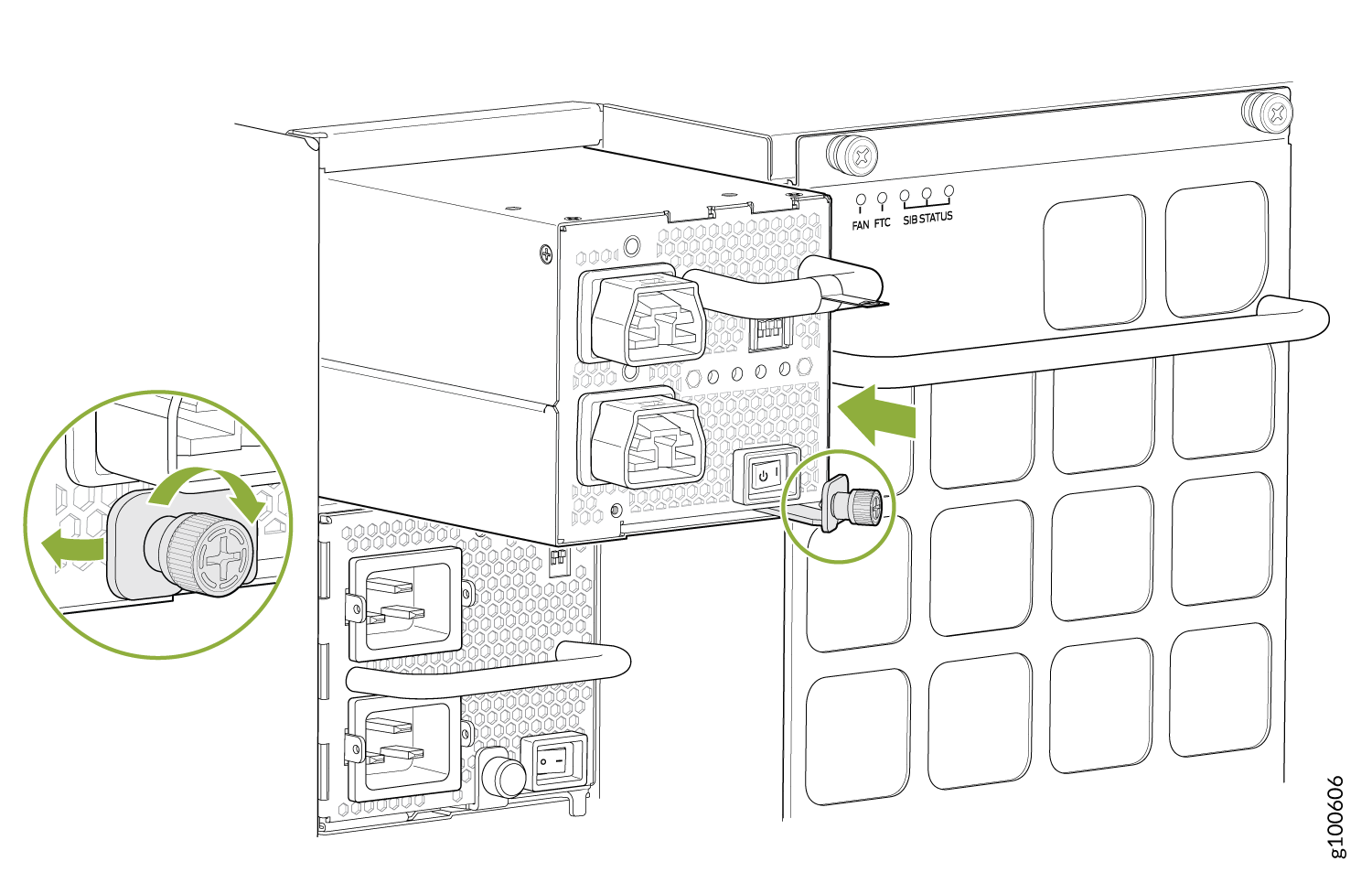

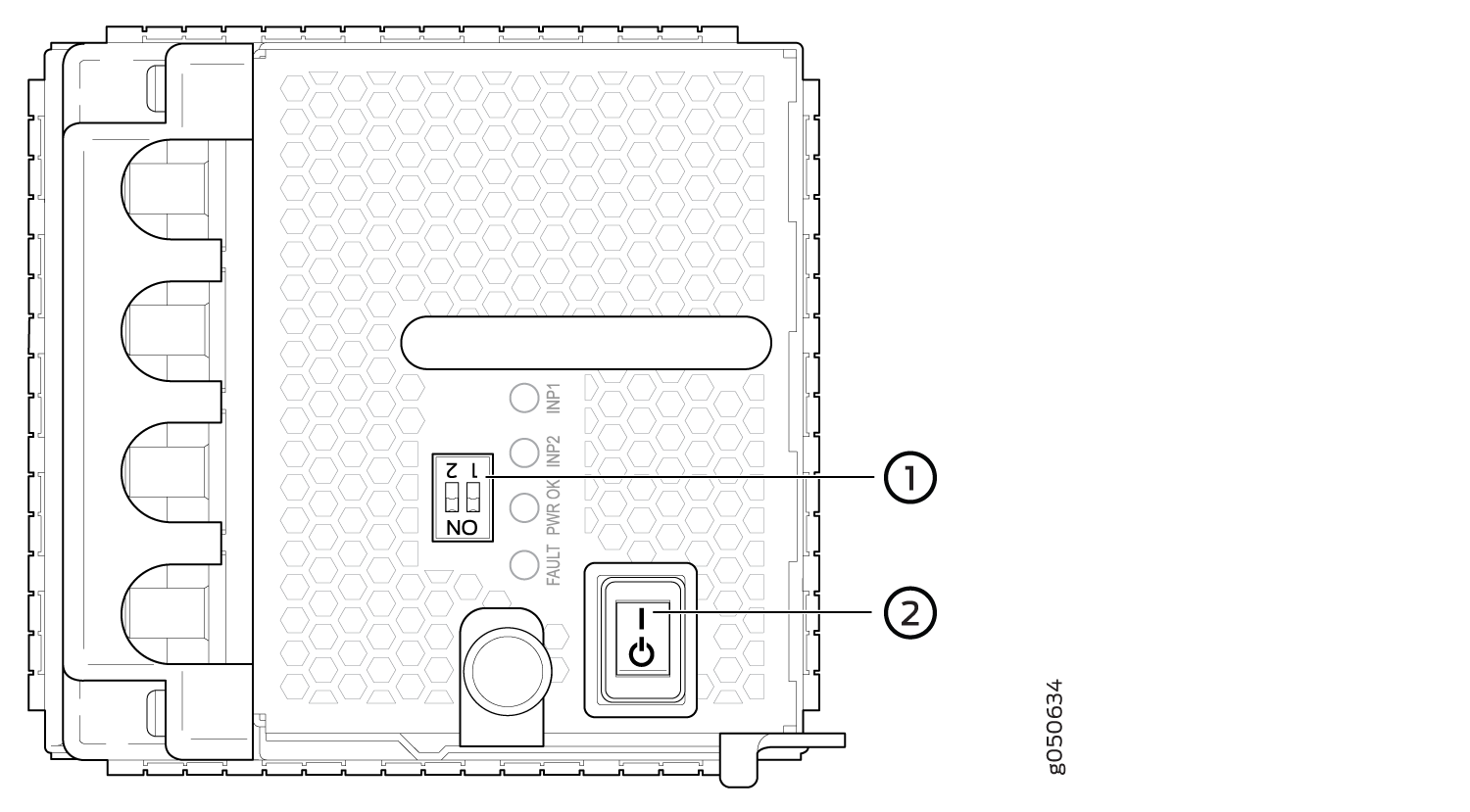

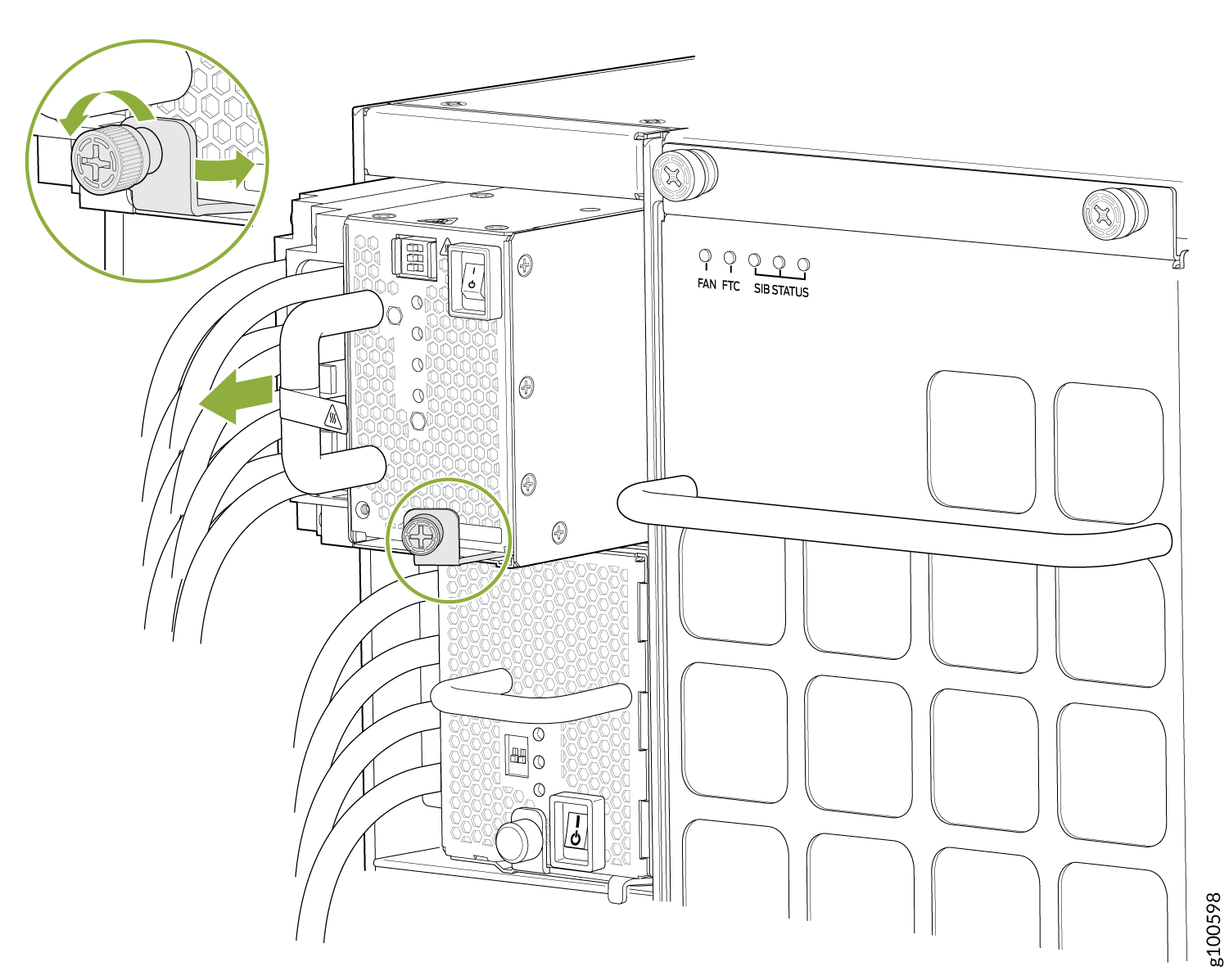

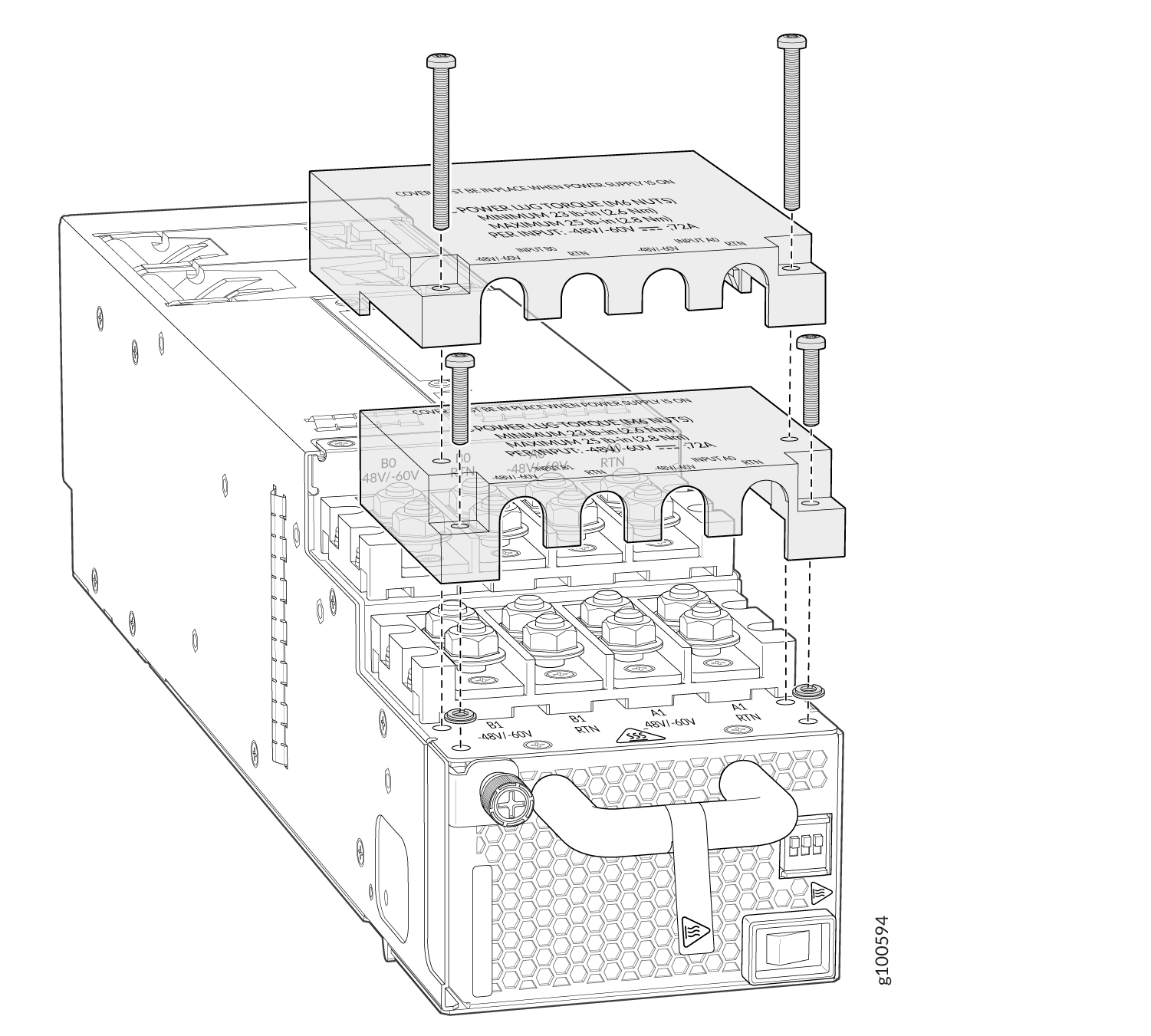

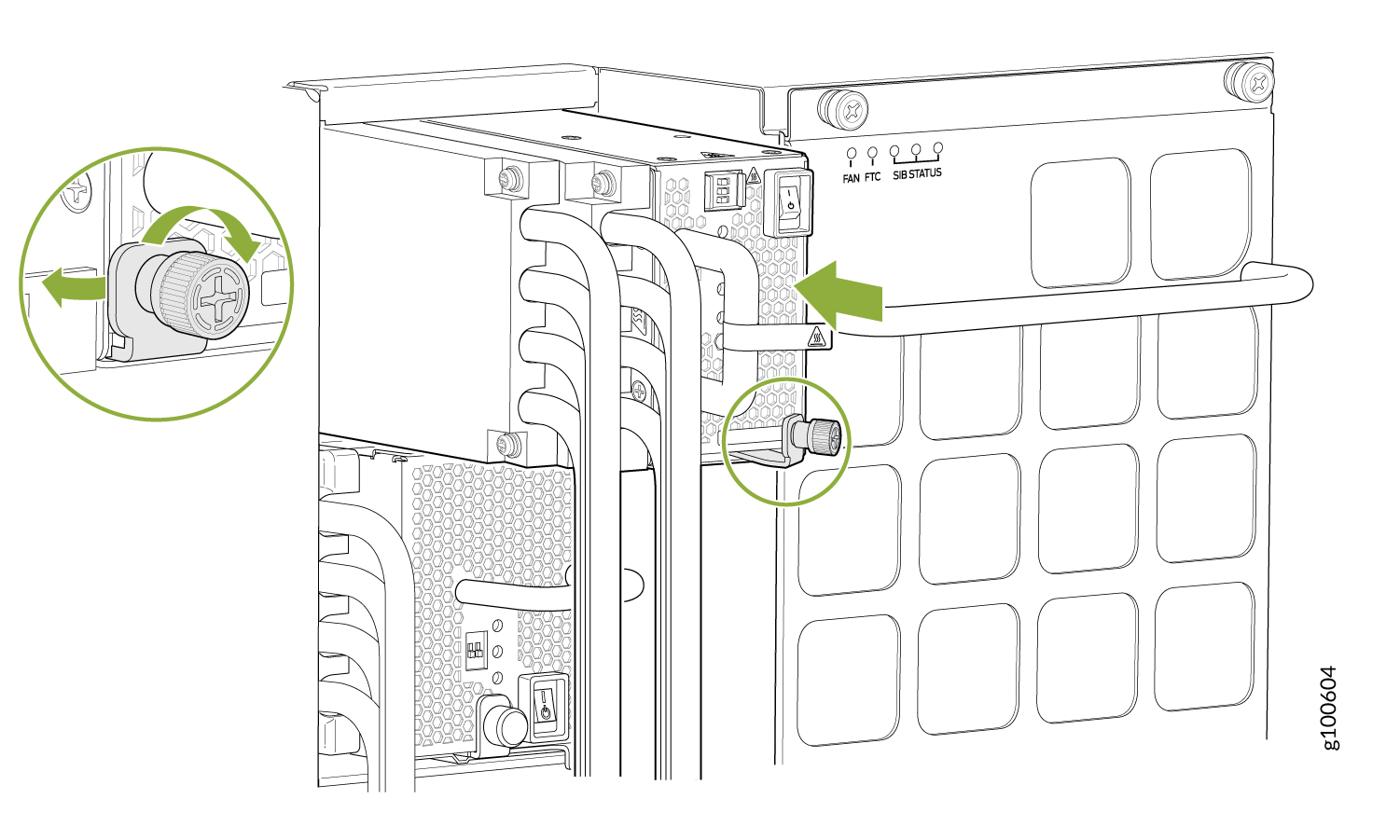

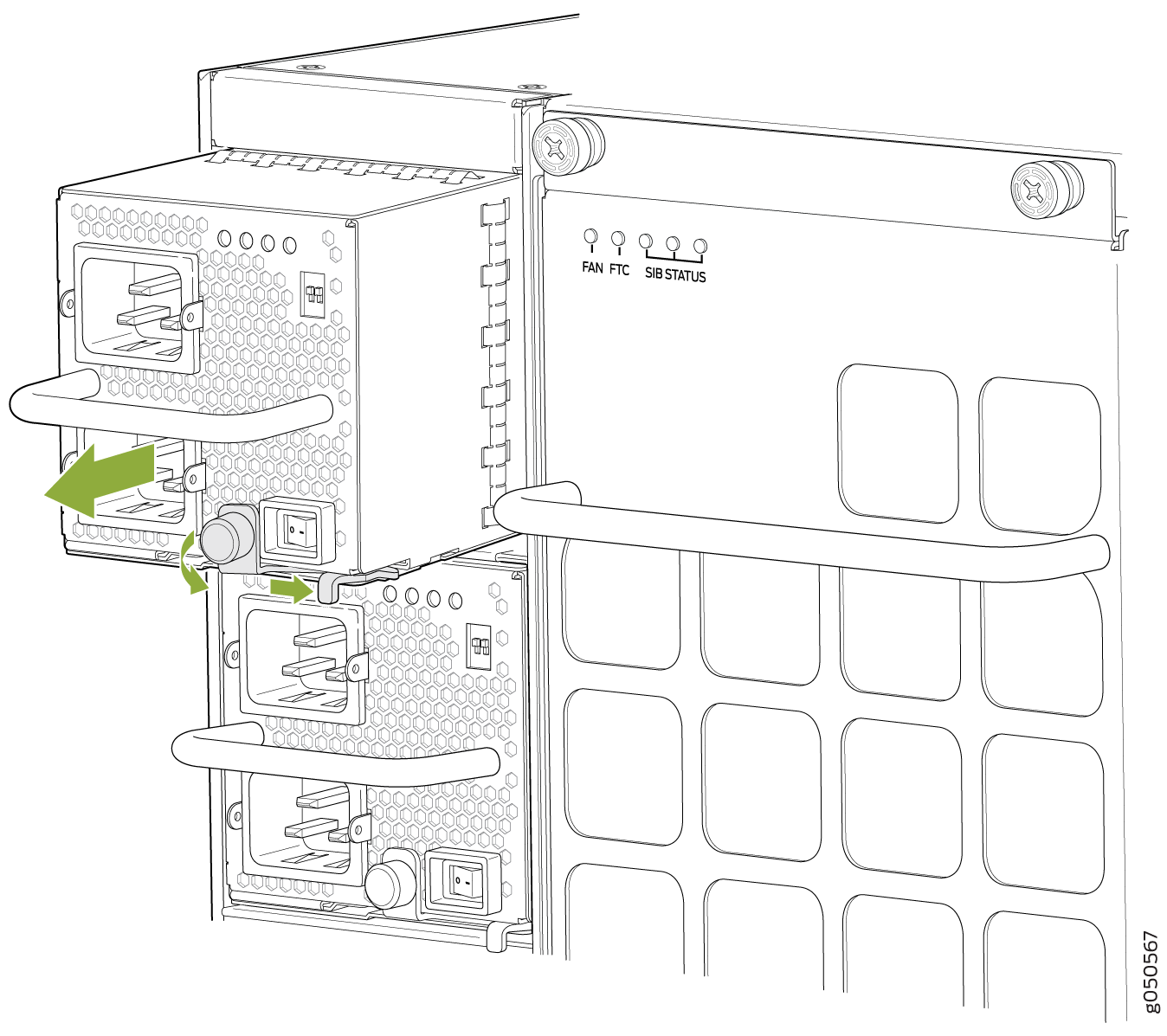

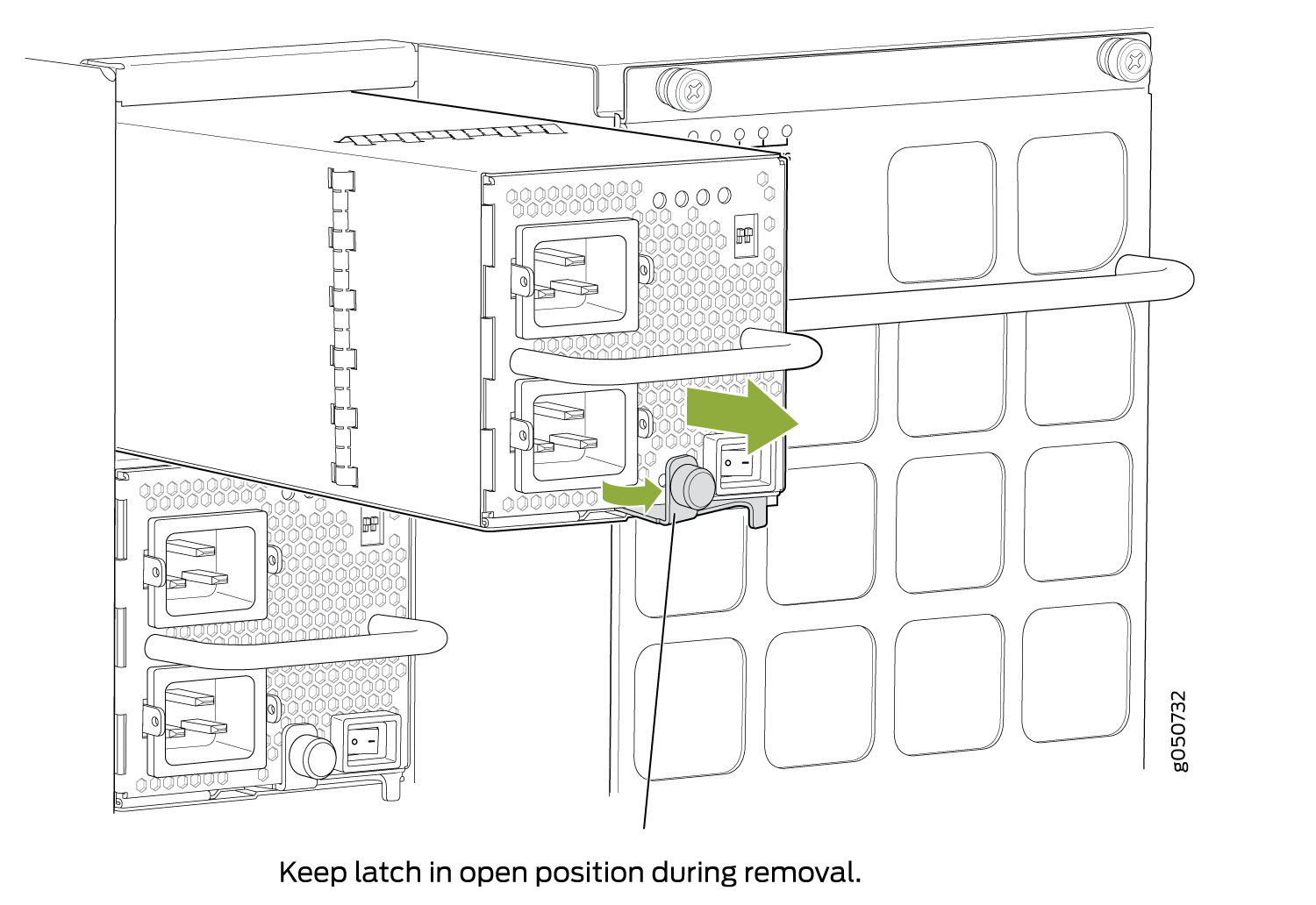

To remove a QFX10000-PWR-DC power supply from a QFX10000 switch (see Figure 28):

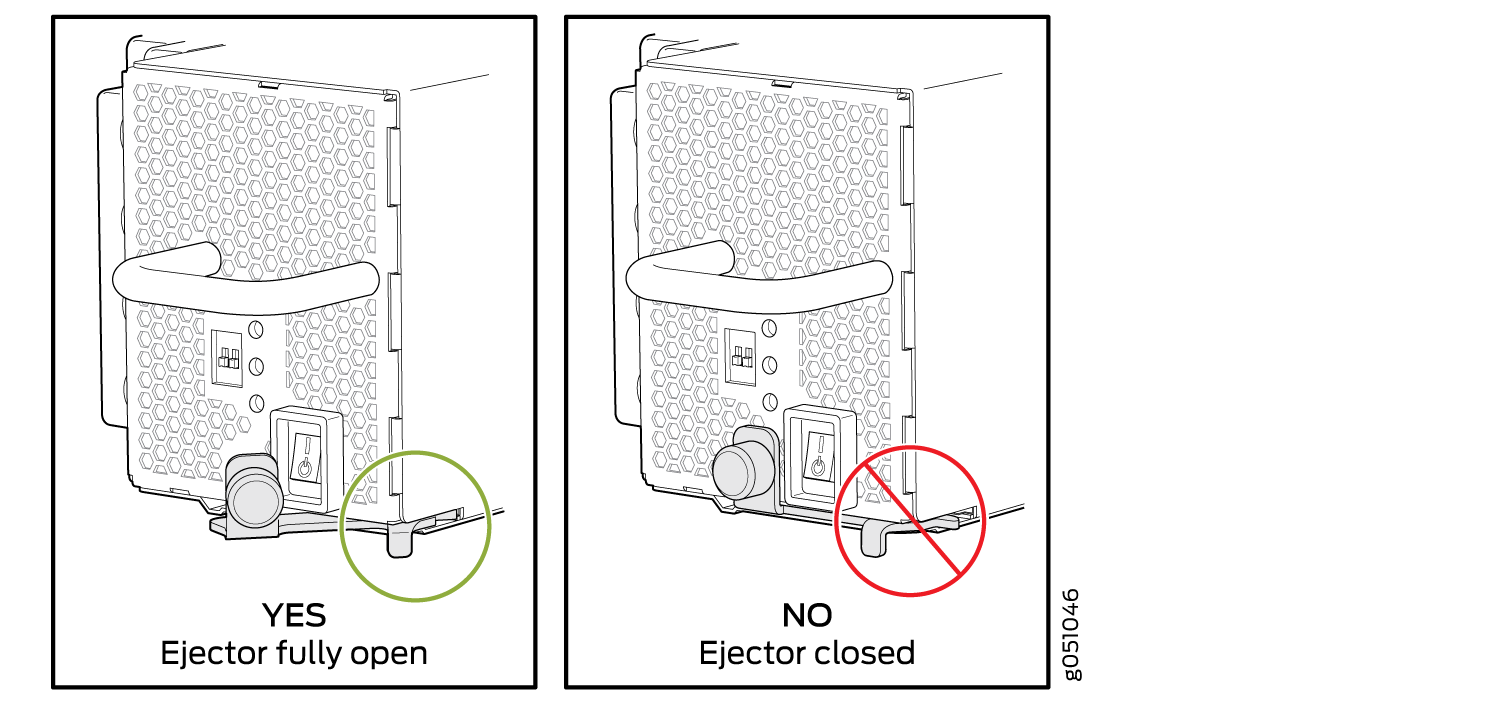

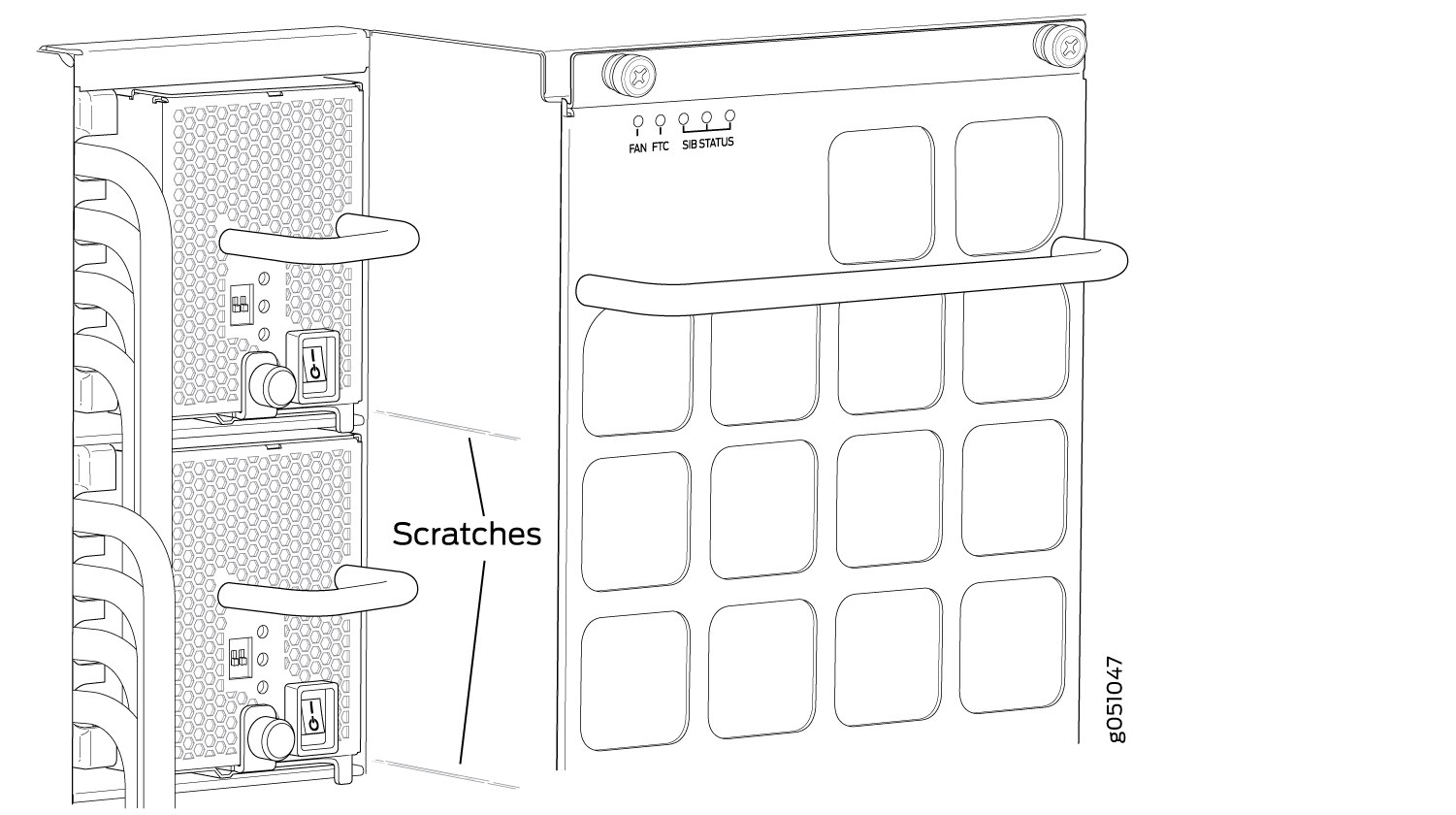

Ensure that the ejector is fully open to avoid scratching the chassis.

|

|

How to Install a QFX10000-PWR-DC Power Supply

Before you install a QFX10000-PWR-DC power supply in the chassis, ensure that you have followed all safety warnings and cautions:

Before performing DC power procedures, ensure that power is removed from the DC circuit. To ensure that all power is off, locate the circuit breaker on the panel board that services the DC circuit, switch the circuit breaker to the OFF position, and tape the switch handle of the circuit breaker in the OFF position.

Before you connect power to the switch, a licensed electrician must attach a cable lug to the grounding and power cables that you supply. A cable with an incorrectly attached lug can damage the switch (for example, by causing a short circuit).

Do not mix AC and DC power supplies in the same chassis.

To meet safety and electromagnetic interference (EMI) requirements and to ensure proper operation, you must connect QFX10008 switches to earth ground before you connect them to power. For installations that require a separate grounding conductor to the chassis, use the protective earthing terminal on the switch chassis to connect to earth ground. For instructions on connecting a QFX10000 switch to ground using a separate grounding conductor, see Connect the QFX10008 or QFX10016 to Earth Ground.

The battery returns of the QFX10000-PWR-DC power supply must be connected as an isolated DC return (DC-I).

Ensure you understand how to prevent ESD damage. See Prevention of Electrostatic Discharge Damage.

Ensure that you have the following parts and tools available to install a QFX10000-PWR-DC power supply:

Electrostatic discharge (ESD) grounding strap

DC power source cables (not provided) with the cable lugs (provided) attached

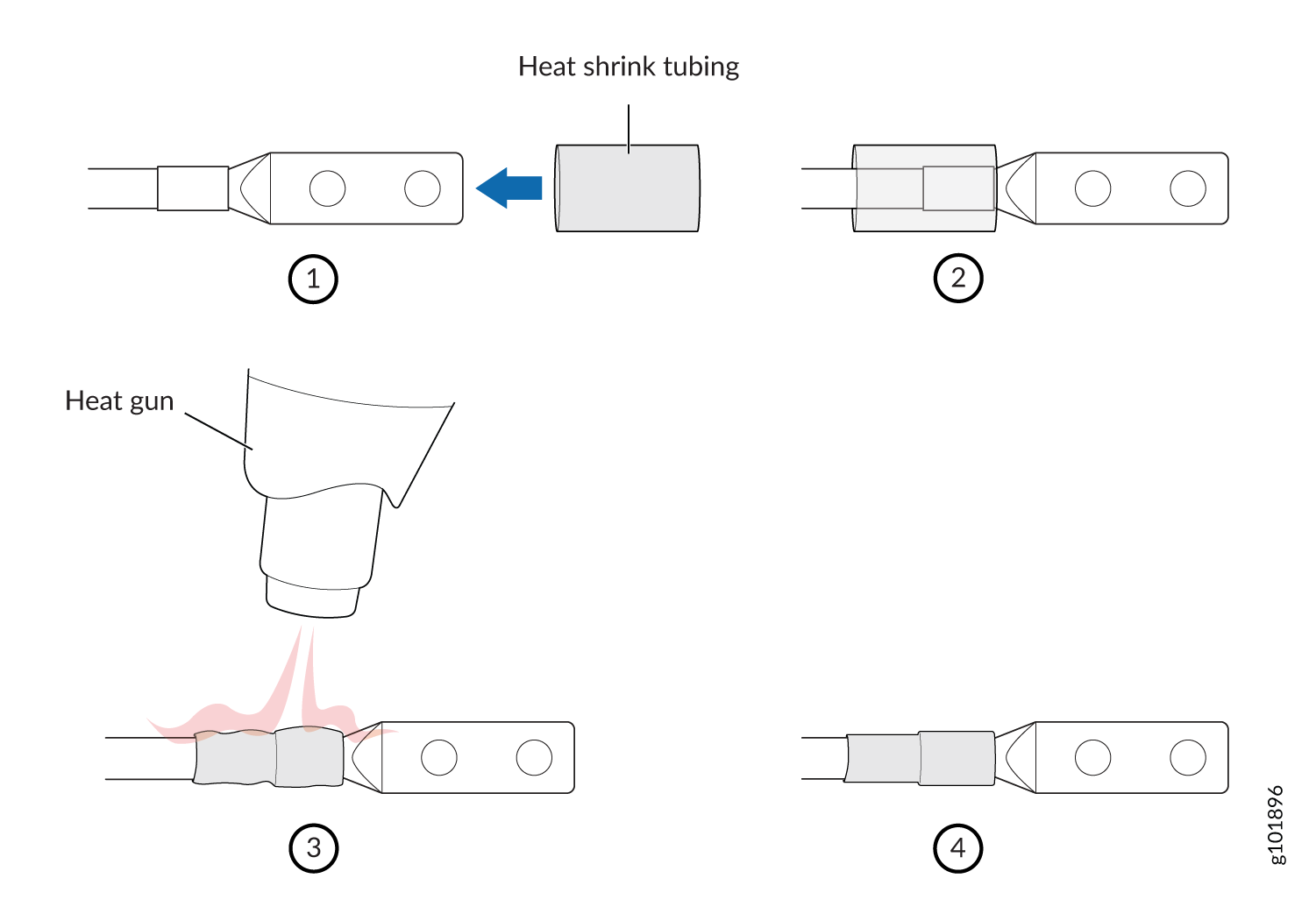

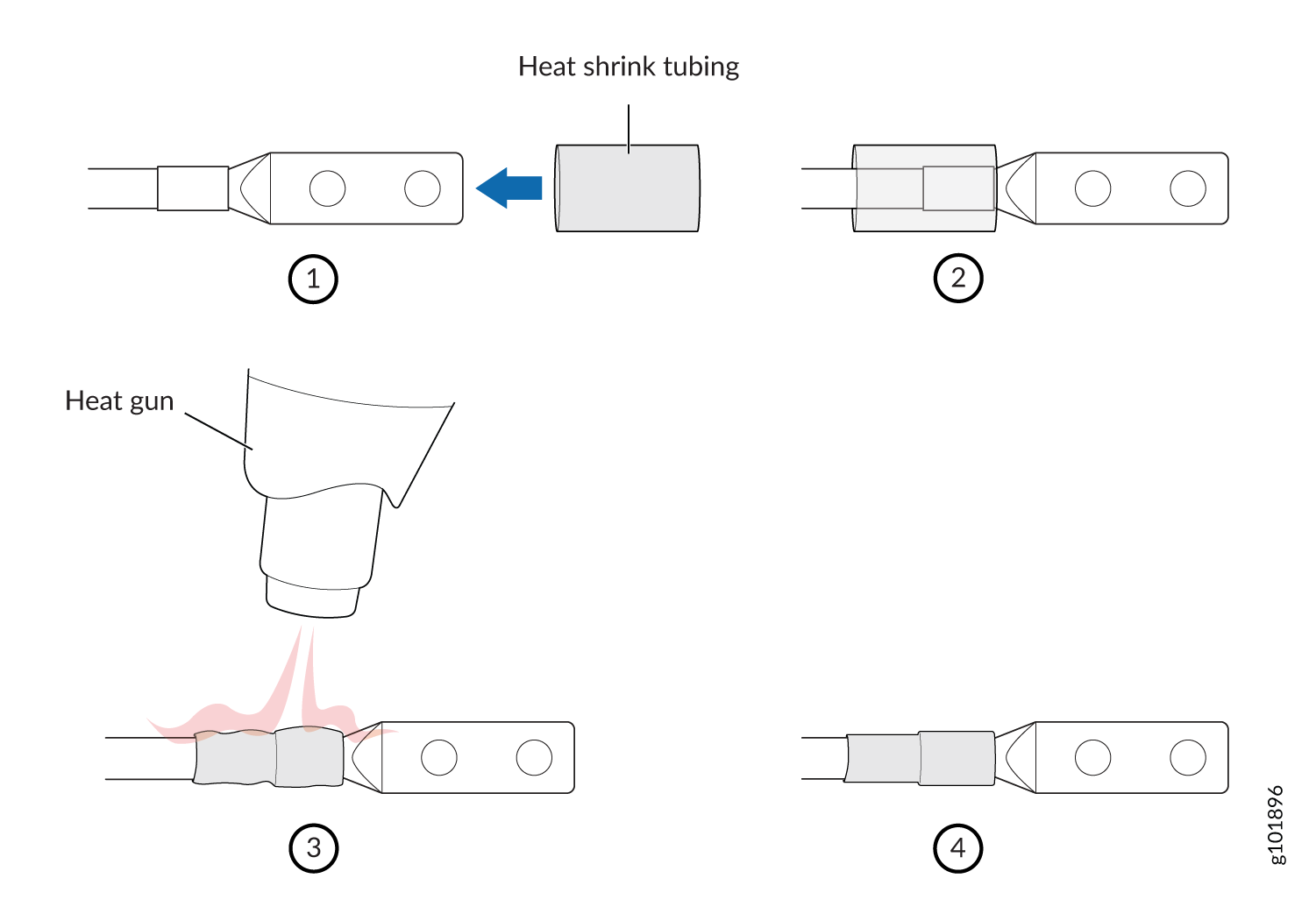

The provided terminal lugs in a QFX10000 are sized for either 4 AWG (21.1 mm2) or 6 AWG (13.3 mm2) power source cables. When running all QFX10000-PWR-DC power supply modules in the chassis, the DC power source cables that you provide must be 6 AWG (13.3 2) mm²) stranded wire. We recommend that you install heat-shrink tubing insulation around the crimped section of the power cables and lugs.

Note:If you upgrade the QFX10000-PWR-DC to a JNP10K-PWR-DC2 and set the input mode to high (80-A), you must use 4 AWG (21.1 mm²) stranded wire.

Note:See the heat symbol

.

Wear heat-resistant gloves while accessing the fan tray and power

supply.

.

Wear heat-resistant gloves while accessing the fan tray and power

supply.13/32 in. (10 mm) nut driver or socket wrench

Phillips (+) screwdrivers, numbers 1 and 2

Multimeter

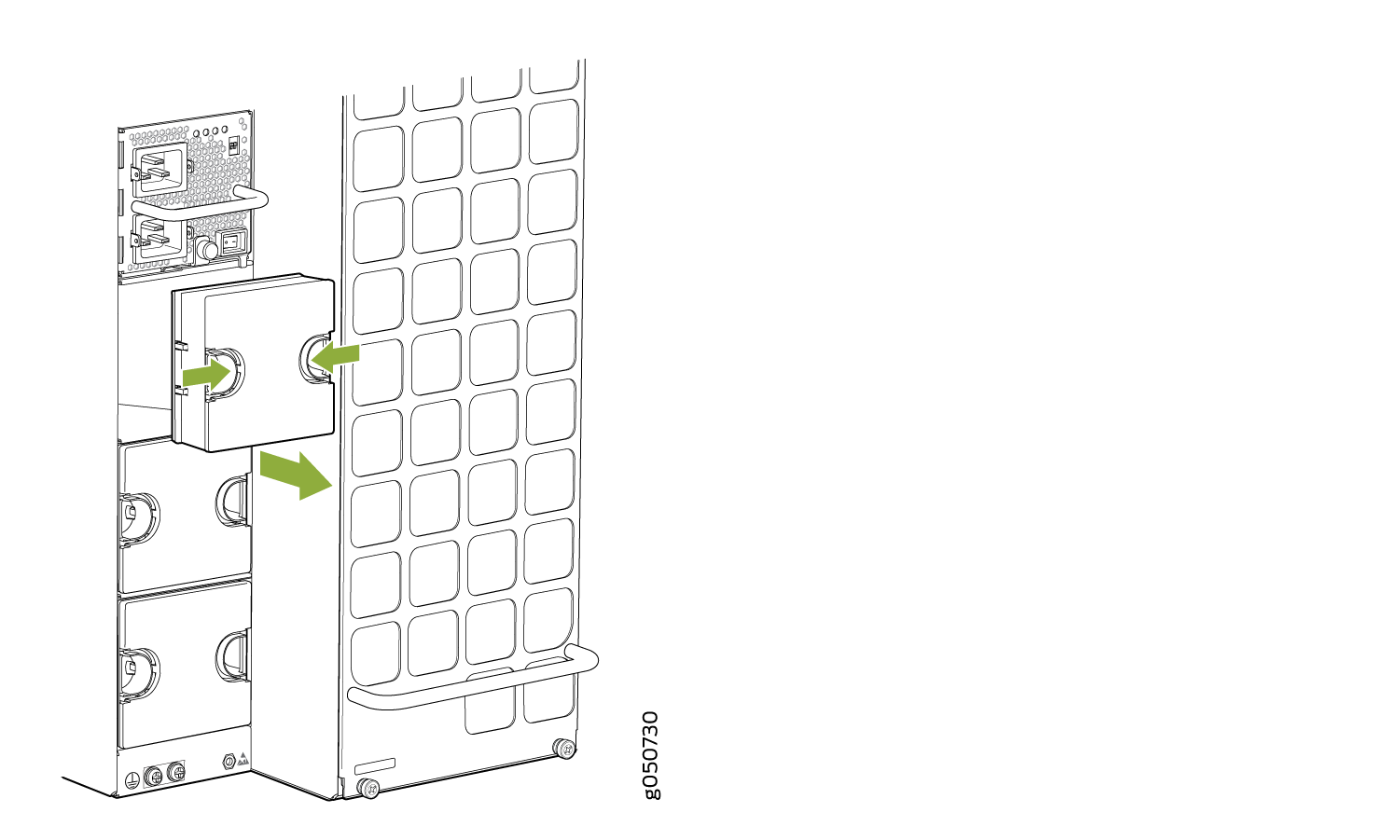

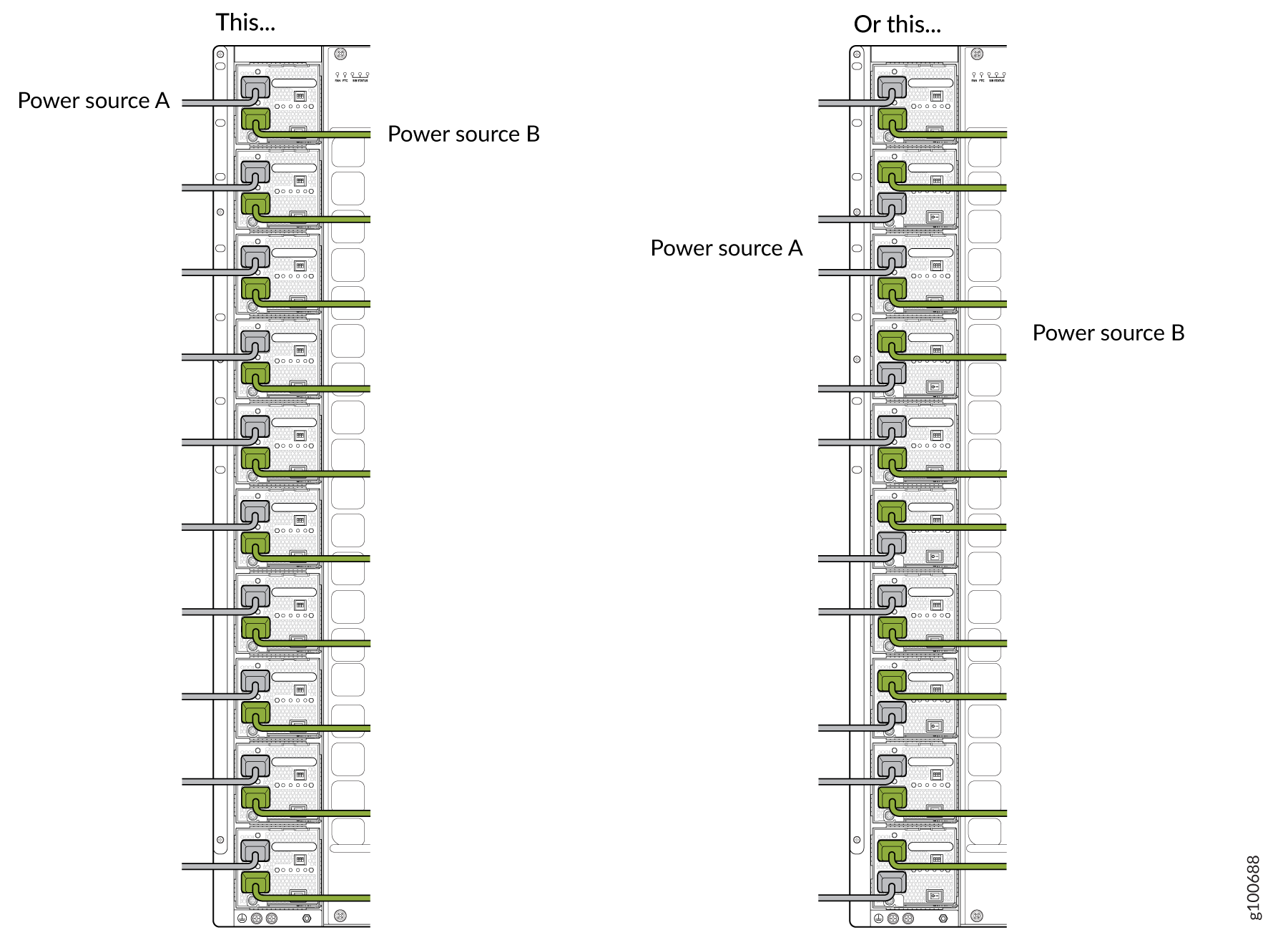

The QFX10000-PWR-DC power supply in QFX10008 and QFX10016 chassis is a hot-removable and hot-insertable field-replaceable unit (FRU). You can install up to 6 QFX10000-PWR-DC power supplies in a QFX10008 switch chassis and 10 in a QFX10016 switch chassis. All DC power supplies install in the rear of the chassis in the slots along the left side of the chassis.

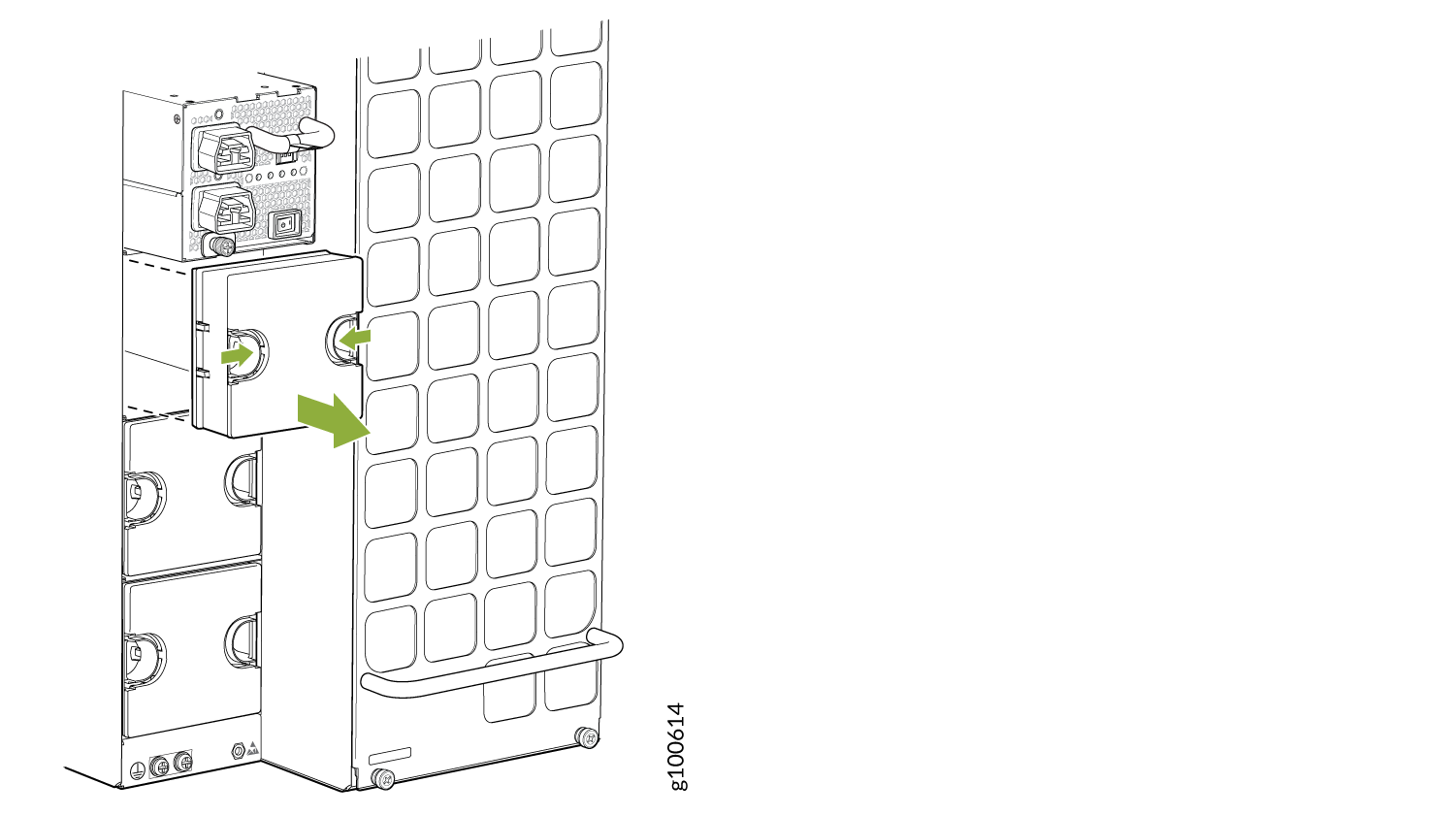

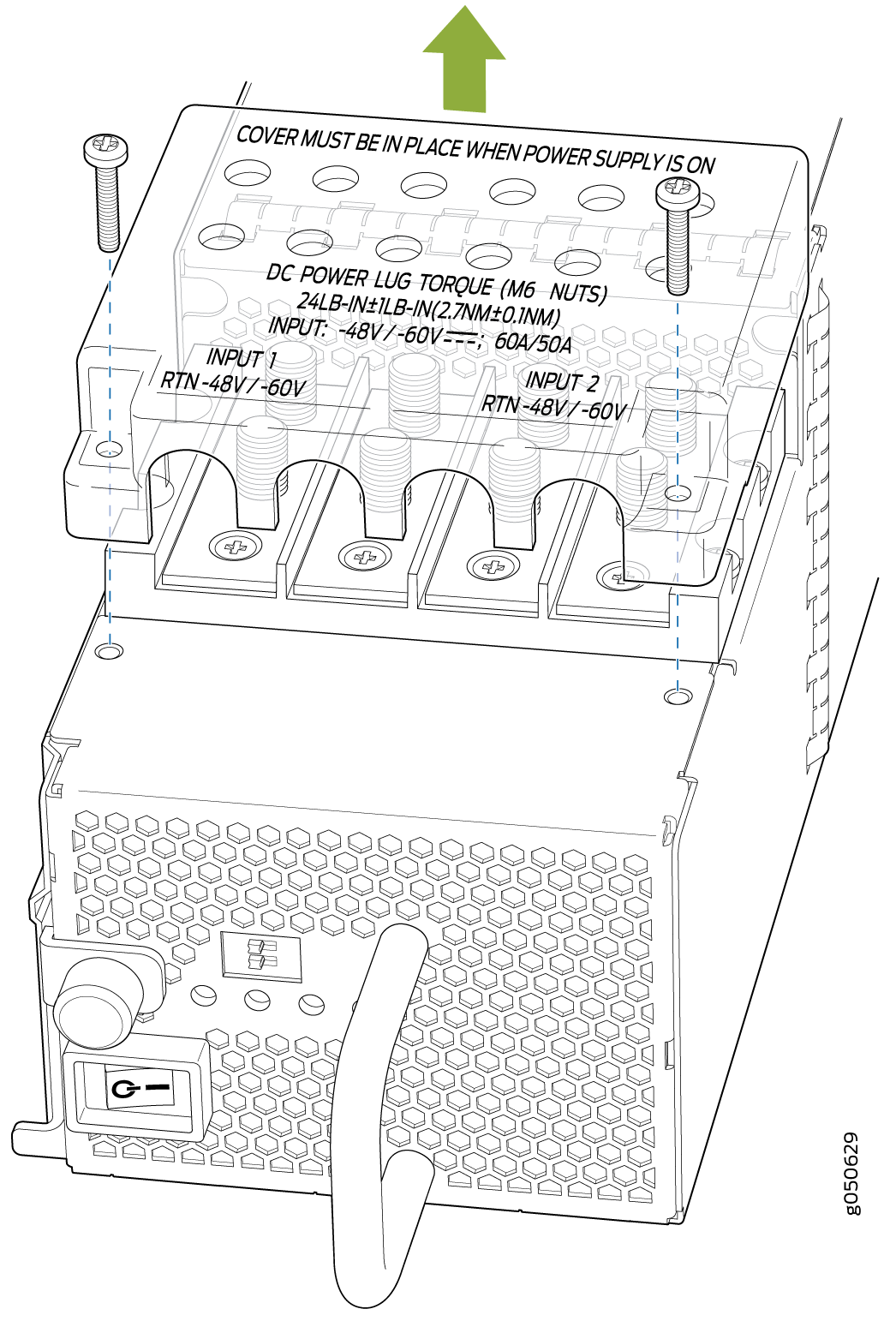

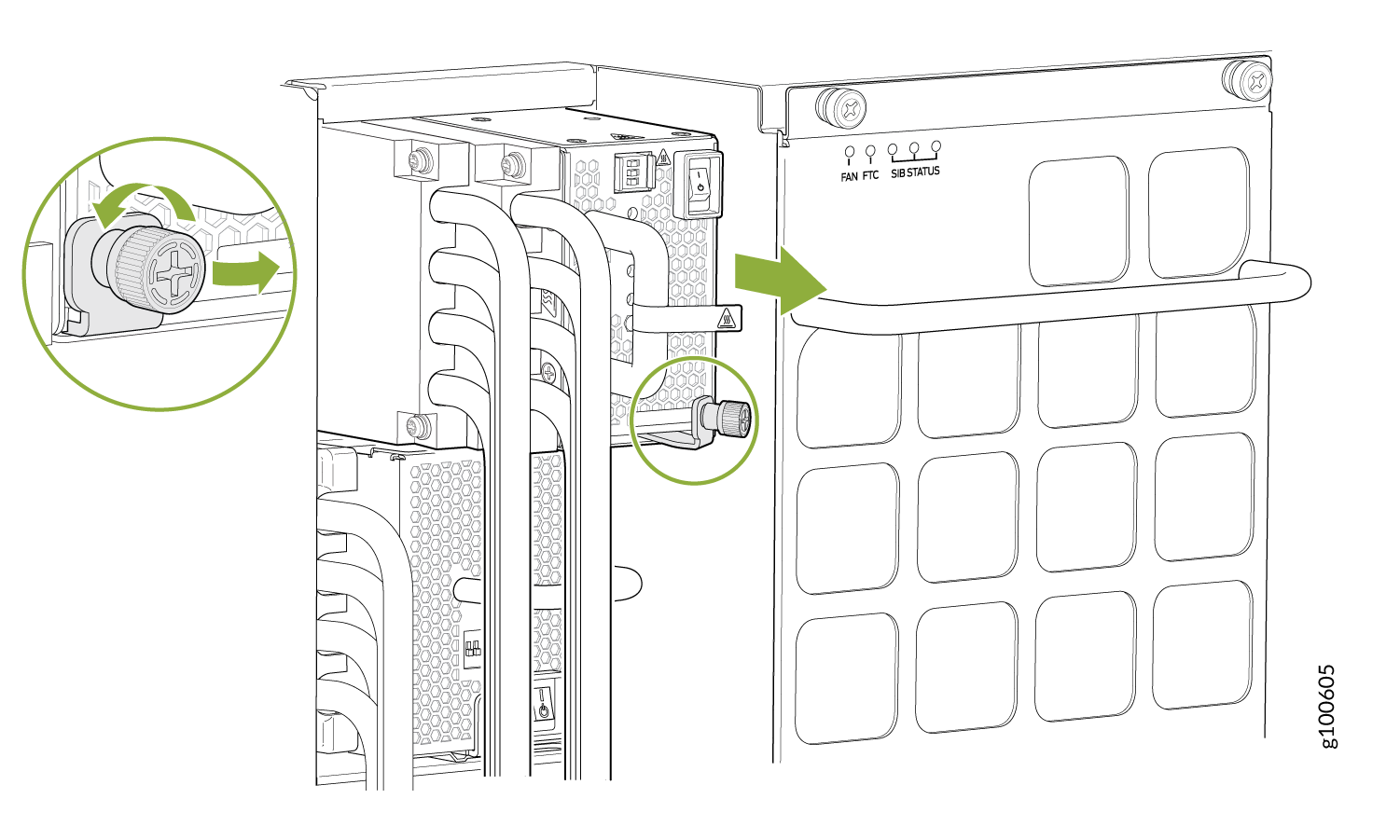

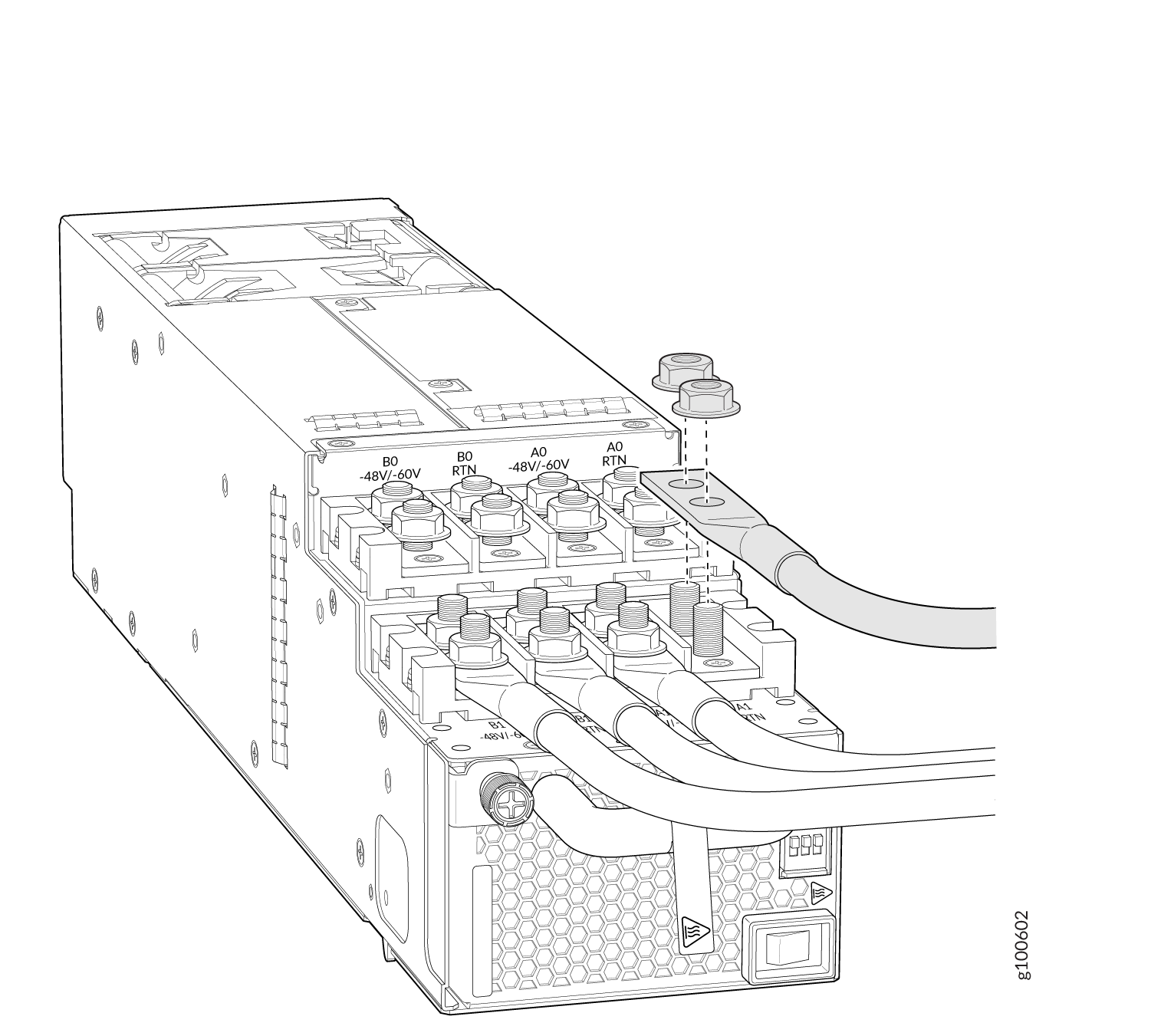

To install a QFX10000-PWR-DC power supply in a QFX10000:

How to Remove a JNP10K-PWR-DC2 Power Supply

Before you remove a DC power supply from the switch:

Ensure you understand how to prevent ESD damage. See Prevention of Electrostatic Discharge Damage.

Ensure that you have the following parts and tools available to remove a JNP10K-PWR-DC2 power supply:

Heat protective gloves able to withstand temperatures in the range of 158°F (70°C) to 176°F (80°C)

Electrostatic discharge (ESD) grounding strap

Phillips (+) screwdriver, numbers 1 and 2

13/32 in. (10 mm) nut driver or socket wrench

Replacement power supply or a cover panel for the power supply slot

The JNP10K-PWR-DC2 power supply in a QFX10000 chassis is a hot-removable and hot-insertable field-replaceable unit (FRU). You remove power supplies from the rear of the chassis.

A working JNP10K-PWR-DC2 power supply can reach temperatures in the range of 158°F (70°C) to 176°F (80°C); In order to avoid injury, do not touch a running power supply with your bare hands.

Before you remove a power supply, ensure that you have power supplies sufficient to power the switch left in the chassis. See QFX10008 Power Planning, QFX10016 Power Planning and Power Requirements for QFX10000 Components.

Do not leave the power supply slot empty for a long time while the switch is operational. Either replace the power supply promptly or install a cover panel over the empty slot.

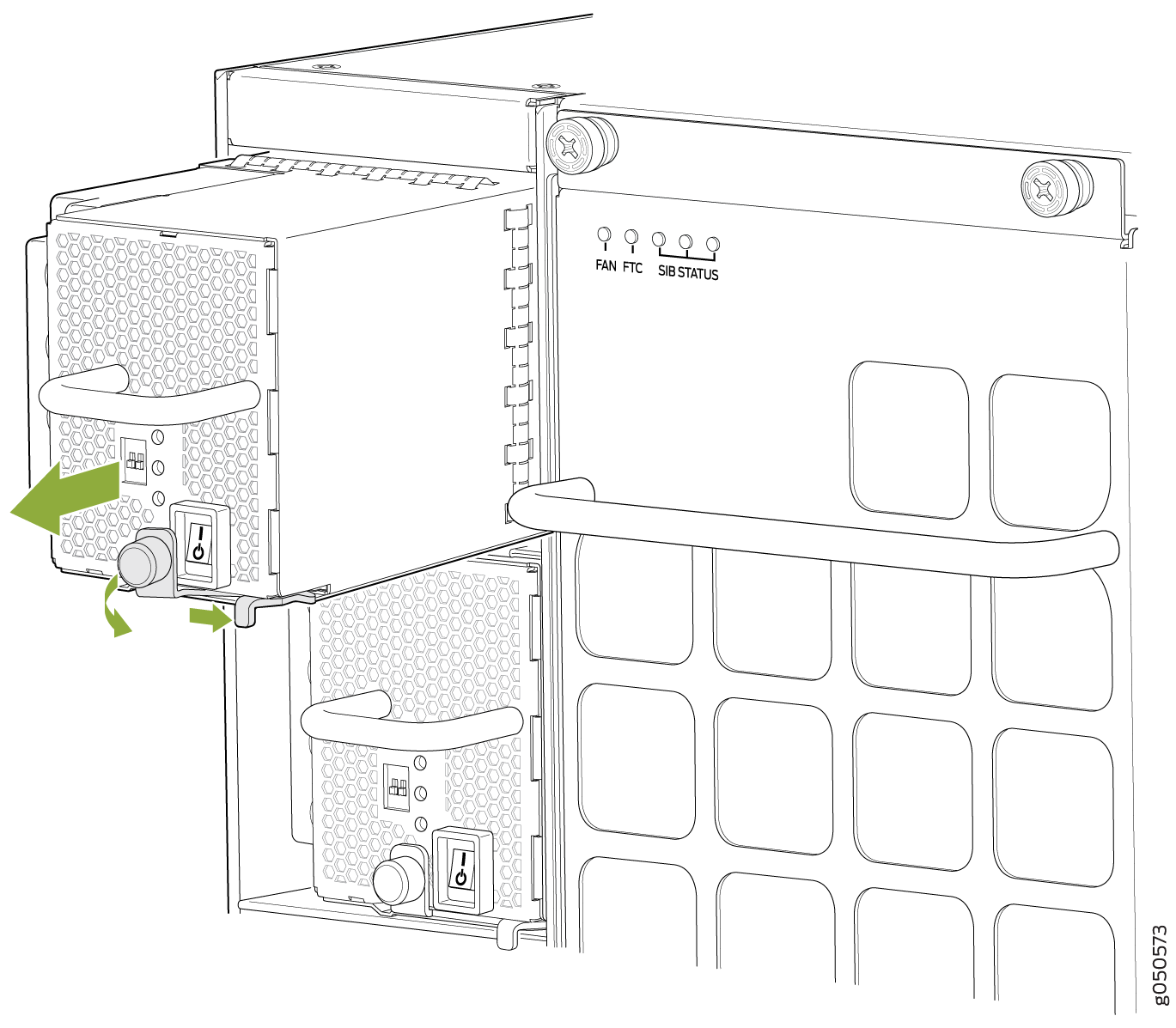

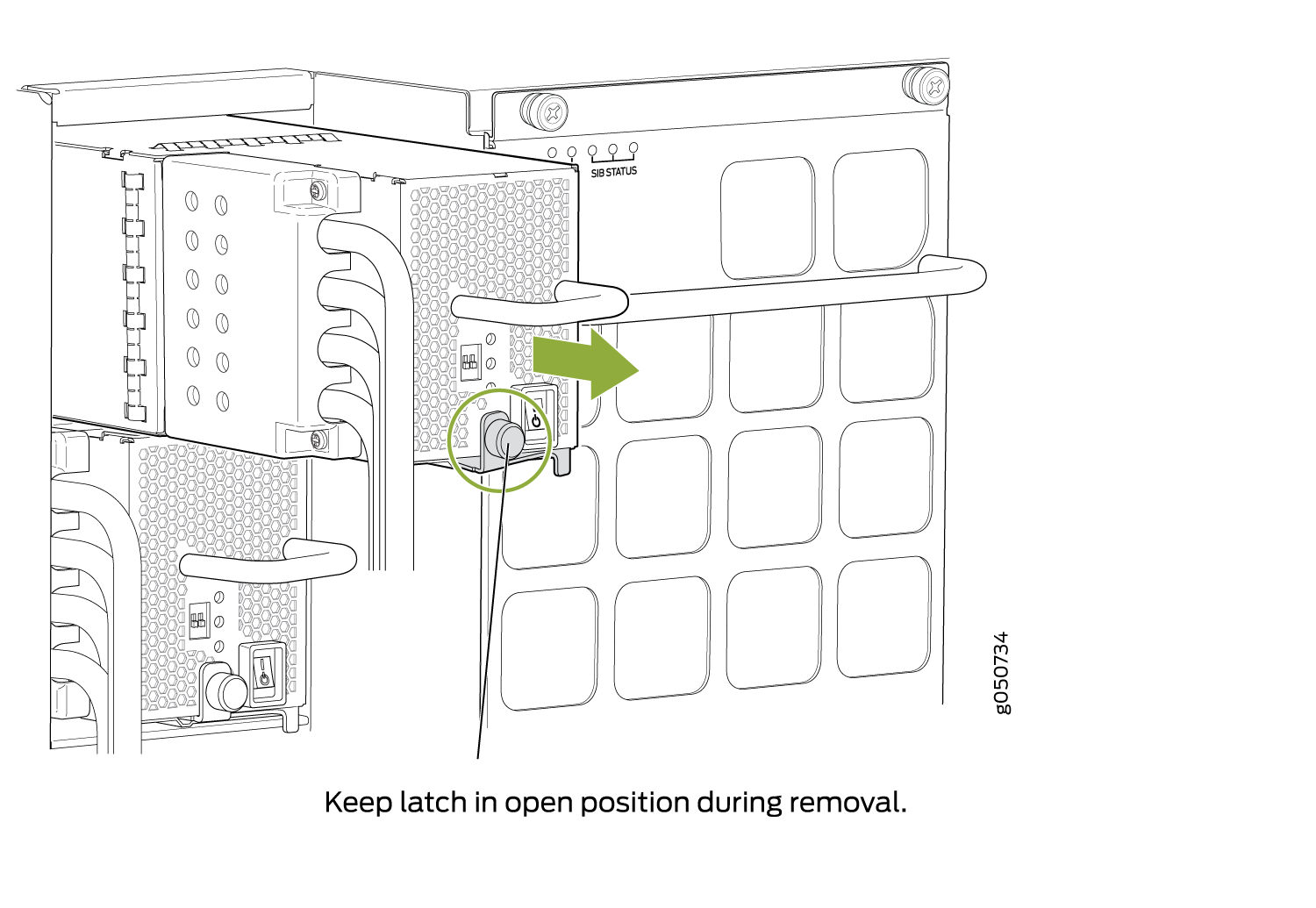

To remove a JNP10K-PWR-DC2 power supply from a QFX10000 switch:

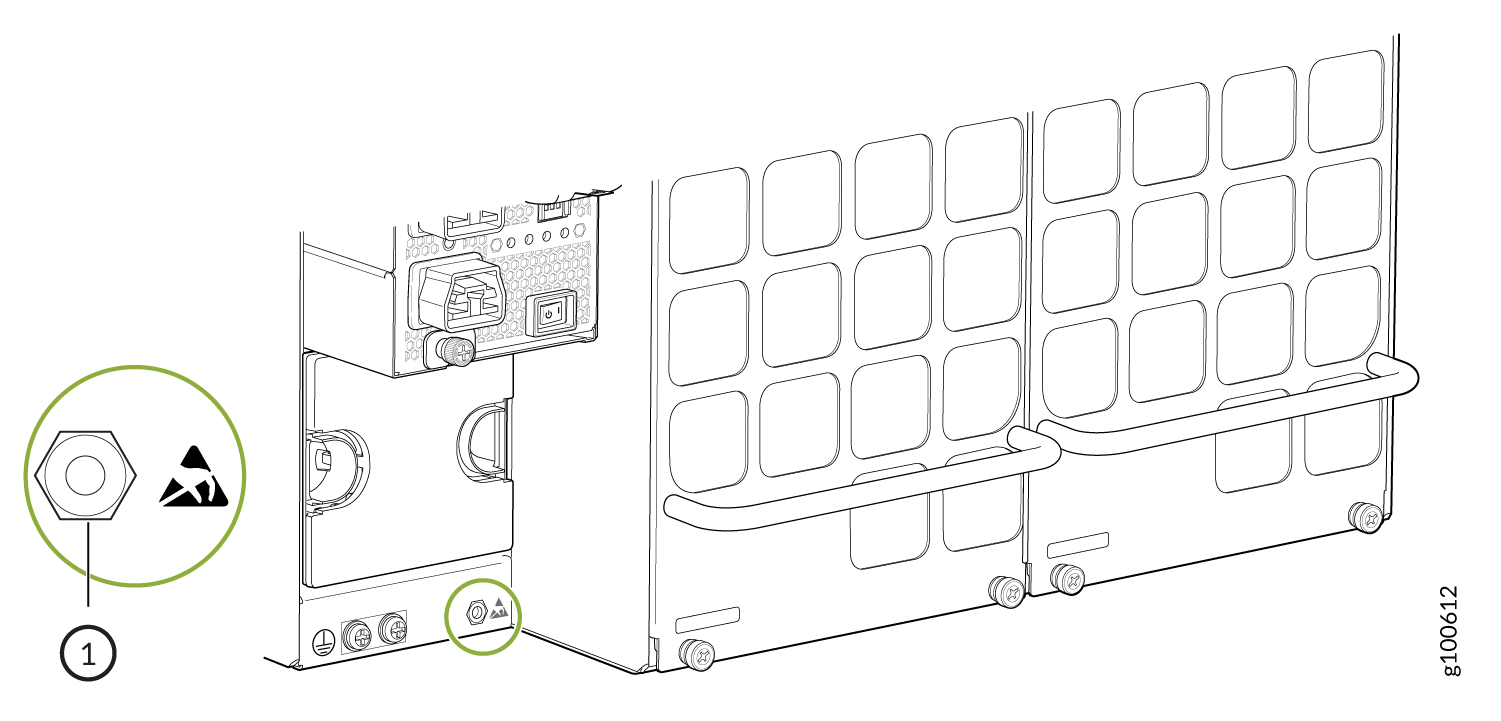

How to Install a JNP10K-PWR-DC2 Power Supply

Before you install an HVDC power supply in the chassis, ensure that you have followed all safety warnings and cautions:

Before performing DC power procedures, ensure that power is removed from the DC circuit. To ensure that all power is off, locate the circuit breaker on the panel board that services the DC circuit, switch the circuit breaker to the OFF position, and tape the switch handle of the circuit breaker in the OFF position.

Protect yourself from severe burns by wearing heat-protective gloves when removing a working HVDC power supply from the chassis. HVDC power supplies can reach in the range of 158°F (70°C) to 176°F (80°C).

Before you connect power to the switch, a licensed electrician must attach a cable lug to the grounding and power cables that you supply. A cable with an incorrectly attached lug can damage the switch (for example, by causing a short circuit).

Do not mix AC, DC, or HVDC power supplies in the same running chassis. You can mix DC and HVDC power supplies while swapping out one type for another during installation.

To meet safety and electromagnetic interference (EMI) requirements and to ensure proper operation, you must connect QFX10008 switches to earth ground before you connect them to power. For installations that require a separate grounding conductor to the chassis, use the protective earthing terminal on the switch chassis to connect to earth ground. For instructions on connecting a QFX10000 switch to ground using a separate grounding conductor, see Connect the QFX10008 or QFX10016 to Earth Ground.

The battery returns of the JNP10K-PWR-DC2 power supply must be connected as an isolated DC return (DC-I).

Ensure you understand how to prevent ESD damage. See Prevention of Electrostatic Discharge Damage.

Ensure that you have the following parts and tools available to install a DC power supply:

Electrostatic discharge (ESD) grounding strap

Use high current cable assembly, CBL-PWR2-BARE (not provided) with the cable lugs (provided) attached

The provided terminal lugs for the JNP10K-PWR-DC2 are Panduit LCD4-14A-L, or equivalent, and sized for 4 AWG (21.1 mm2) power source cables. We recommend that you install heat-shrink tubing insulation around the crimped section of the power cables and lugs.

13/32 in. (10 mm) nut driver or socket wrench

Phillips (+) screwdrivers, numbers 1 and 2

Multimeter

The JNP10K-PWR-DC2 power supply in a QFX10000 chassis is a hot-removable and hot-insertable field-replaceable unit (FRU). You can install up to 6 power supplies in a QFX10008 switch chassis. All HVDC power supplies install in the rear of the chassis in the slots along the left side of the chassis.

To install a JNP10K-PWR-DC2 power supply in a QFX10008 or QFX10016 :