Connect the SRX4120 to Power

This section takes you through the steps and safety precautions to be foolowing while connnecting power to the SRX4120, to prevent equipment damage and personal injury.

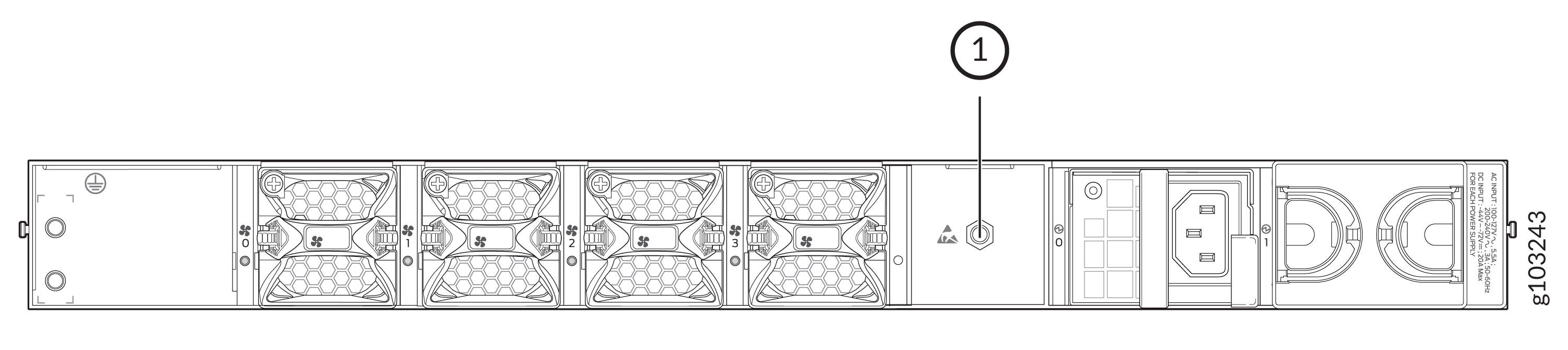

Ground the SRX4120

To meet safety and electromagnetic interference (EMI) requirements and to ensure proper operation, you must connect the SRX4120 to an earth ground before you connect it to power.

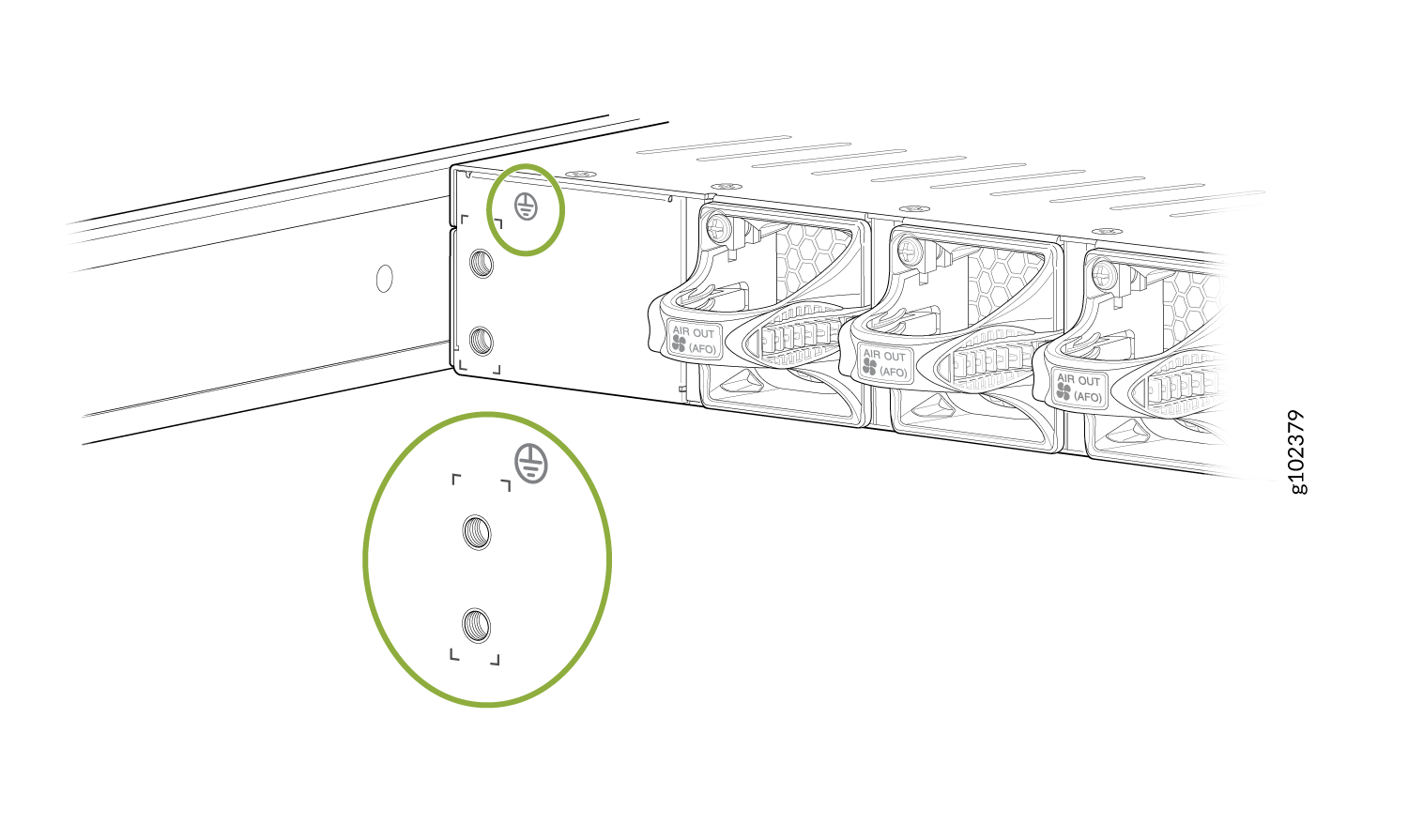

Before you connect an earth ground to the protective earthing terminal of the device, ensure that a licensed electrician attaches an appropriate grounding terminal to the grounding cable you supply. Using a grounding cable with an incorrectly -attached terminal can damage the device.

Before connecting the device to an earth ground, ensure that you have the following parts and tools:

-

An electrostatic discharge (ESD) grounding strap.

-

A grounding cable for your device—The grounding cable must be 6 AWG (4.11 mm²) stranded wire and rated 90 °C or per local electrical code.

-

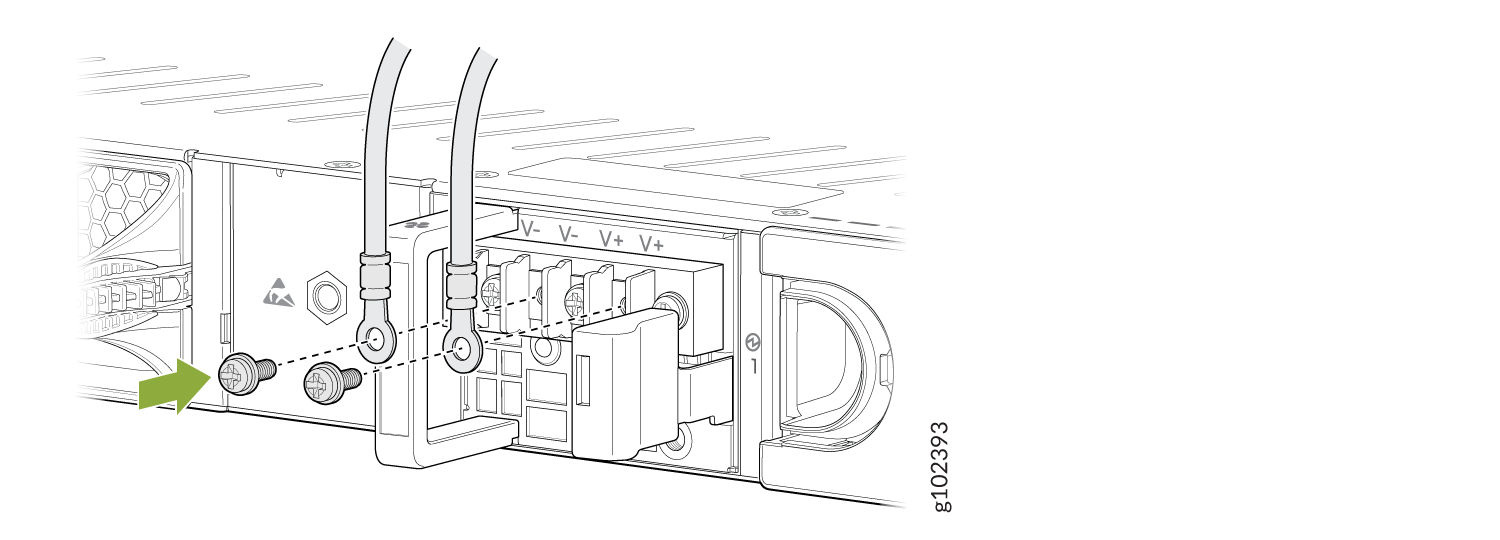

A grounding 2-hole terminal for your grounding cable—This attaches to the chassis grounding point. The Panduit LCD6-14A-L terminal lugs, or equivalent are sized for 6 AWG (4.11 mm²) power source cables.

-

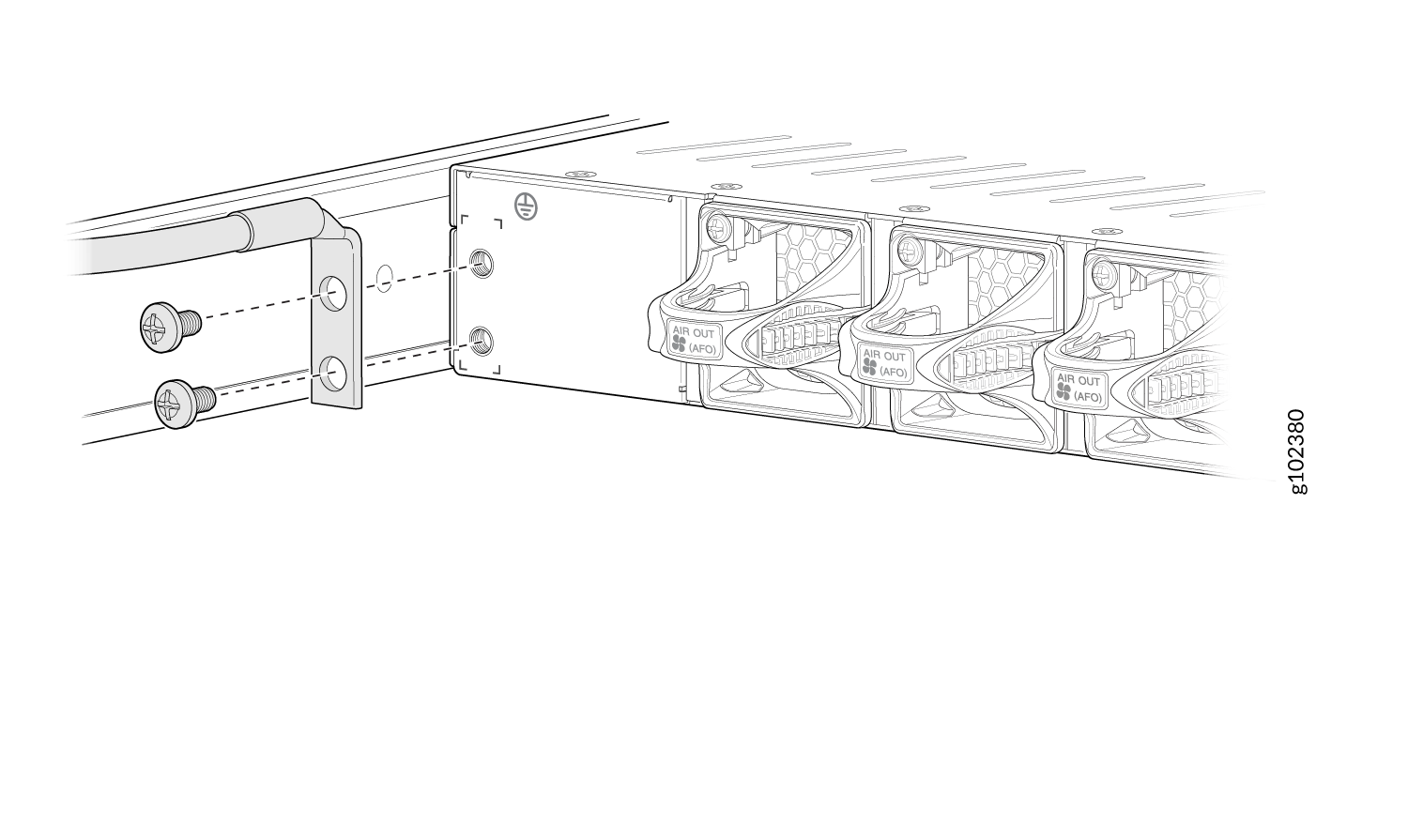

Two pan head M5 x10 mm screws with integrated split washers (not provided)—The screws and washers are used to secure the grounding lug to the protective earthing terminal.

-

A Phillips screwdriver to tighten the screw.

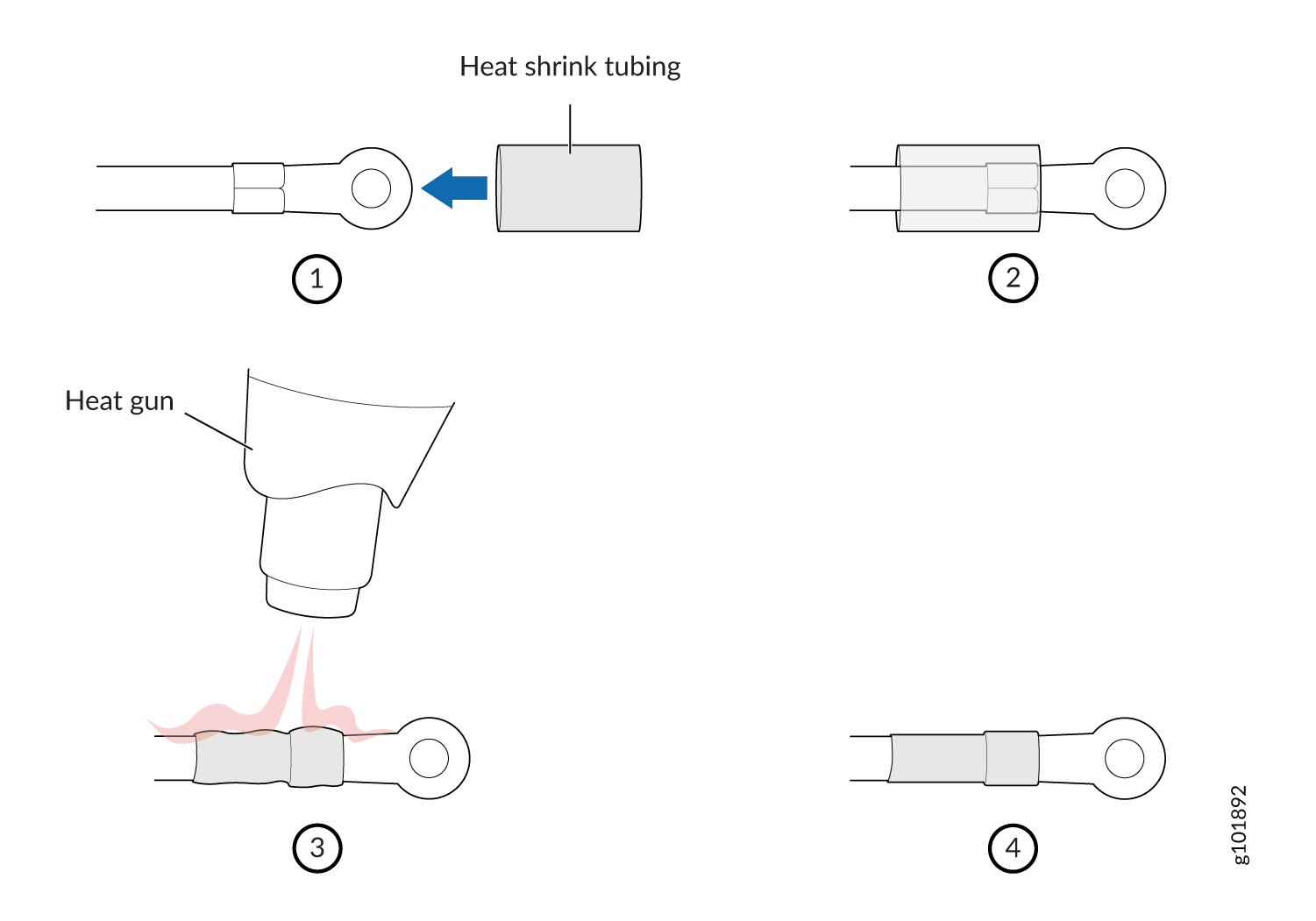

You must install heat-shrink tubing insulation around the crimped section of the power cables and lugs.

To ground the SRX4120, connect a grounding cable to earth ground. Attach the grounding cable to the chassis grounding point. Under all circumstances, use this grounding connection to ground the chassis.

To ground the device:

Install Heat-Shrink Tubing on a Power Cable

Connect AC Power to the SRX4120

Before you begin:

-

Ensure that you have grounded the SRX4120.

-

Ensure that you have read the guidelines and precautions in the Juniper Networks Safety Guide.

-

Ensure that you have a power cord appropriate for your geographical location available to connect AC power to the device.

-

Ensure that you fully insert the PSUs into the chassis.

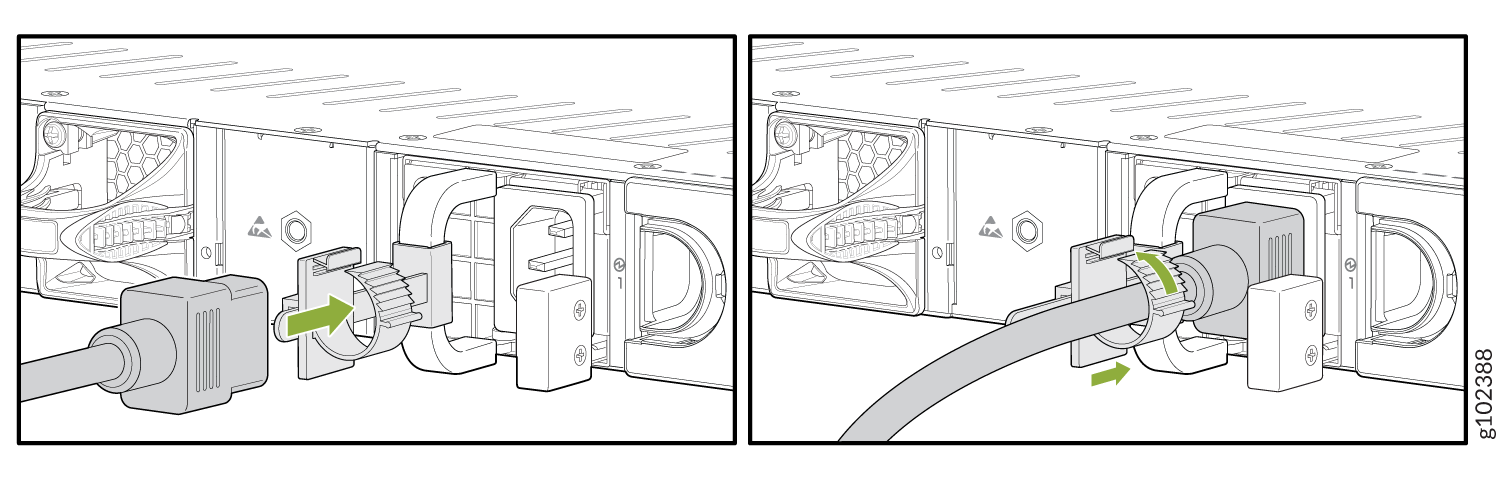

Connect the JPSU-450W-AC to Power

To connect the JPSU-450W-AC to AC power:

Connect DC Power to the SRX4120

Before you begin:

-

Ensure that you have grounded the SRX4120.

-

Ensure that you have installed heat-shrink tubing as described in Install Heat-Shrink Tubing on a Power Cable.

-

Ensure that you have read the guidelines and precautions in the Juniper Networks Safety Guide.

-

Ensure that you fully insert the PSUs into the chassis.

Before performing the following procedure, ensure that you remove the power from the DC circuit. To ensure that all power is off, locate the circuit breaker on the panel board that services the DC circuit. Switch the circuit breaker to the OFF position (0), and tape the switch handle of the circuit breaker in the OFF position.

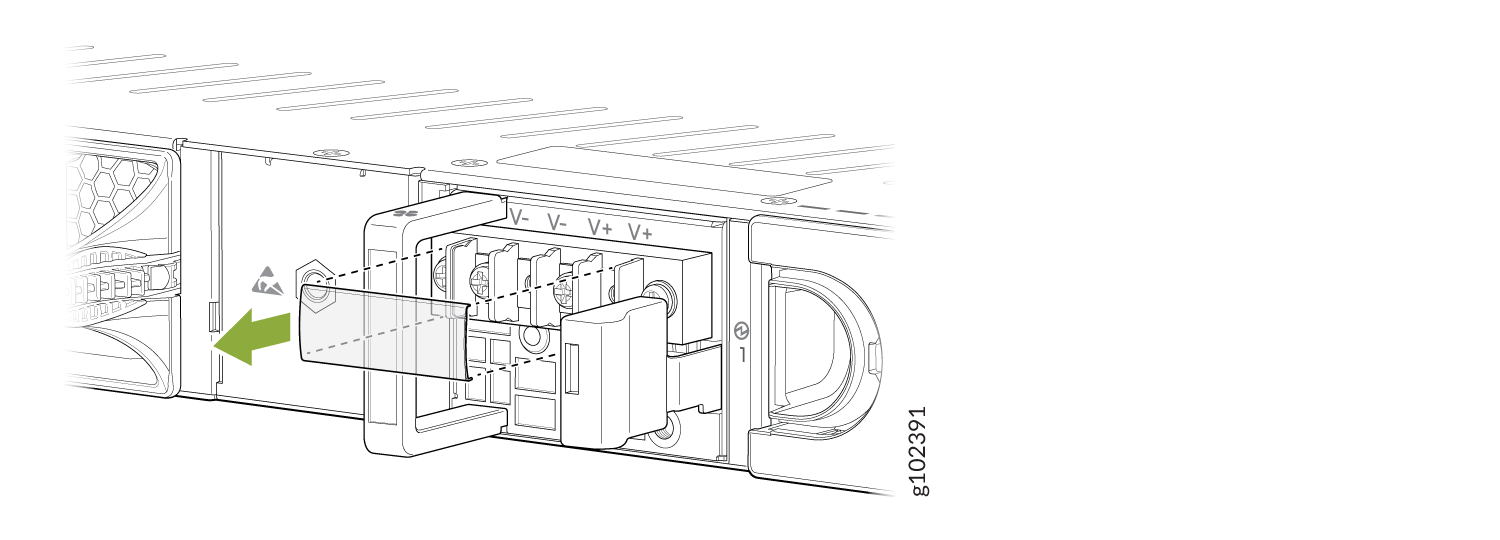

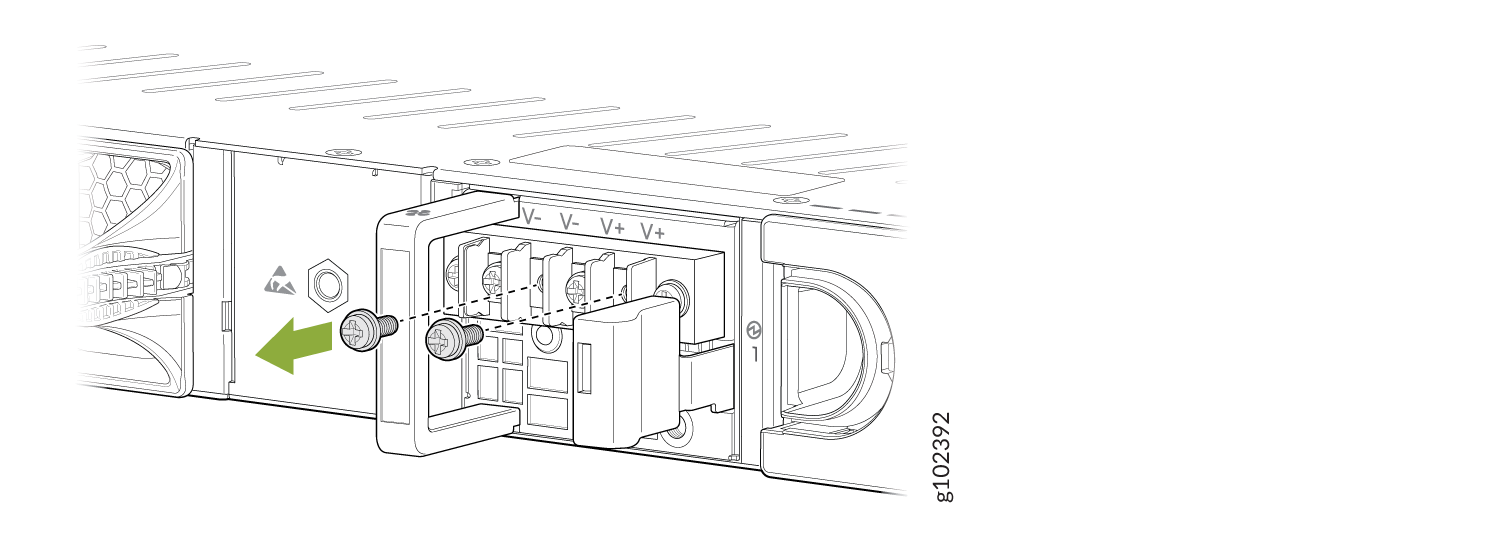

Connect the JPSU-650W-DC-AFO to Power

The DC power cables for the JPSU-650W-DC-AFO are rated 16 AWG.

To connect the JPSU-650W-DC-AFO to power:

Power Off the SRX4120

You can power off the SRX4120 in any of the following ways:

-

Graceful shutdown:

-

Using hardware—Press and immediately release the Power button.

-

Using the CLI—Use the

request system power-offcommand.

The device begins gracefully shutting down the operating system (OS) and then powers itself off.

CAUTION:Use the graceful shutdown method to power off or reboot the firewall.

-

-

Forced shutdown—Press the Power button and hold it for ten seconds. The device immediately powers itself off without shutting down the OS.

CAUTION:Use the forced shutdown method as a last resort to recover the firewall if the firewall OS is not responding to the graceful shutdown method.

To remove power completely from the device, unplug the AC power cord or DC power supply cable.

After powering off a PSU, wait at least 60 seconds before turning it back on. After powering on a PSU, wait at least 10 seconds before turning it off.

When the system is completely powered off and you turn on the power supply, the

device starts as the PSU completes its startup sequence. If the device finishes

starting and you need to power off the system again, first issue the

request vmhost halt command.

The fans in the PSU continue to rotate even after you power off the SRX4120. To stop the fans, remove the power cord from the PSU. The fans will stop in a few seconds.

After turning on the PSU, it can take up to 60 seconds for status indicators—such

as the PWR LED and the show chassis command display—to indicate

that the PSU is functioning normally. Ignore error indicators that appear during

the first 60 seconds.