Connecting the QFX5230-64CD to Power

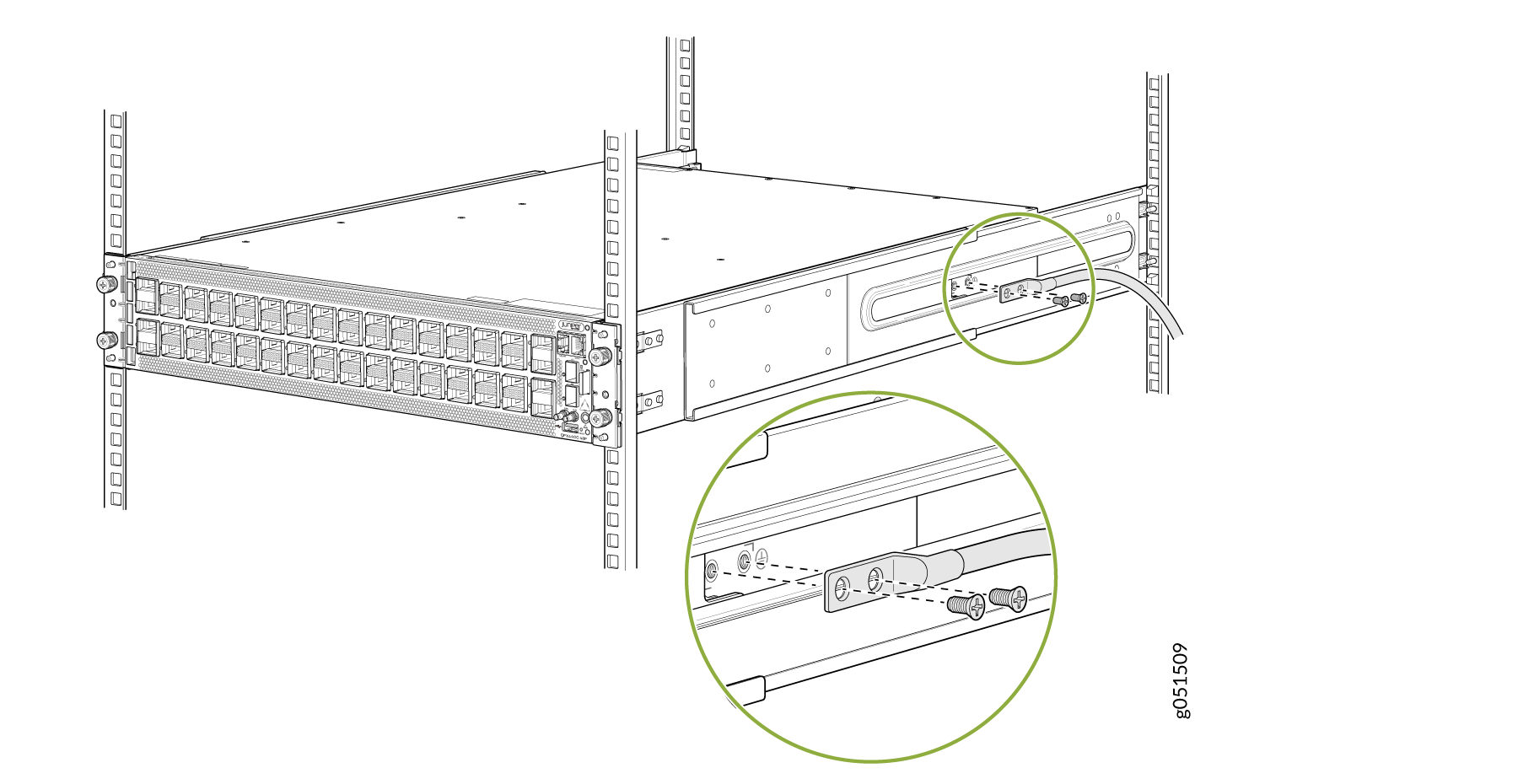

Ground the QFX5230-64CD Switch

To connect earth ground to a QFX5230-64CD switch:

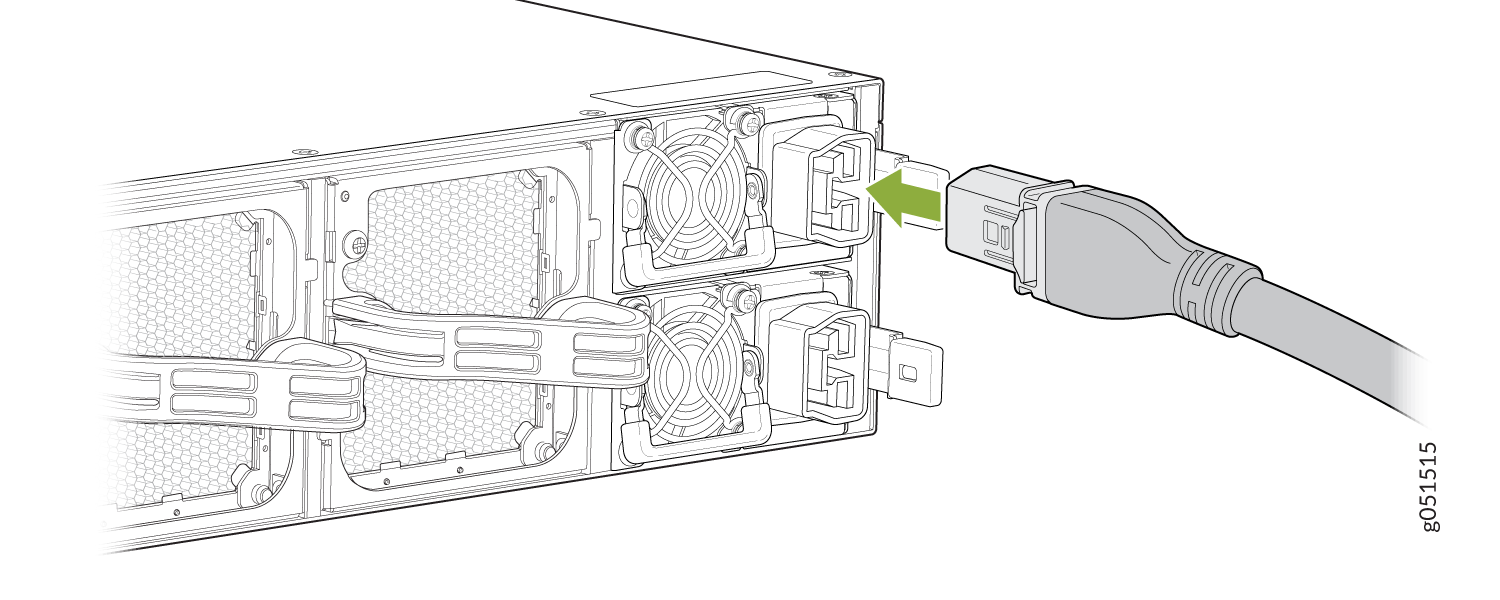

Connect AC Power to a QFX5230-64CD Switch

Before you begin to connect power to the switch, be sure you understand how to prevent ESD damage. See Prevention of Electrostatic Discharge Damage.

To meet safety and electromagnetic interference (EMI) requirements and to ensure proper operation, you must connect the QFX5230-64CD switch to earth ground before you connect it to power.

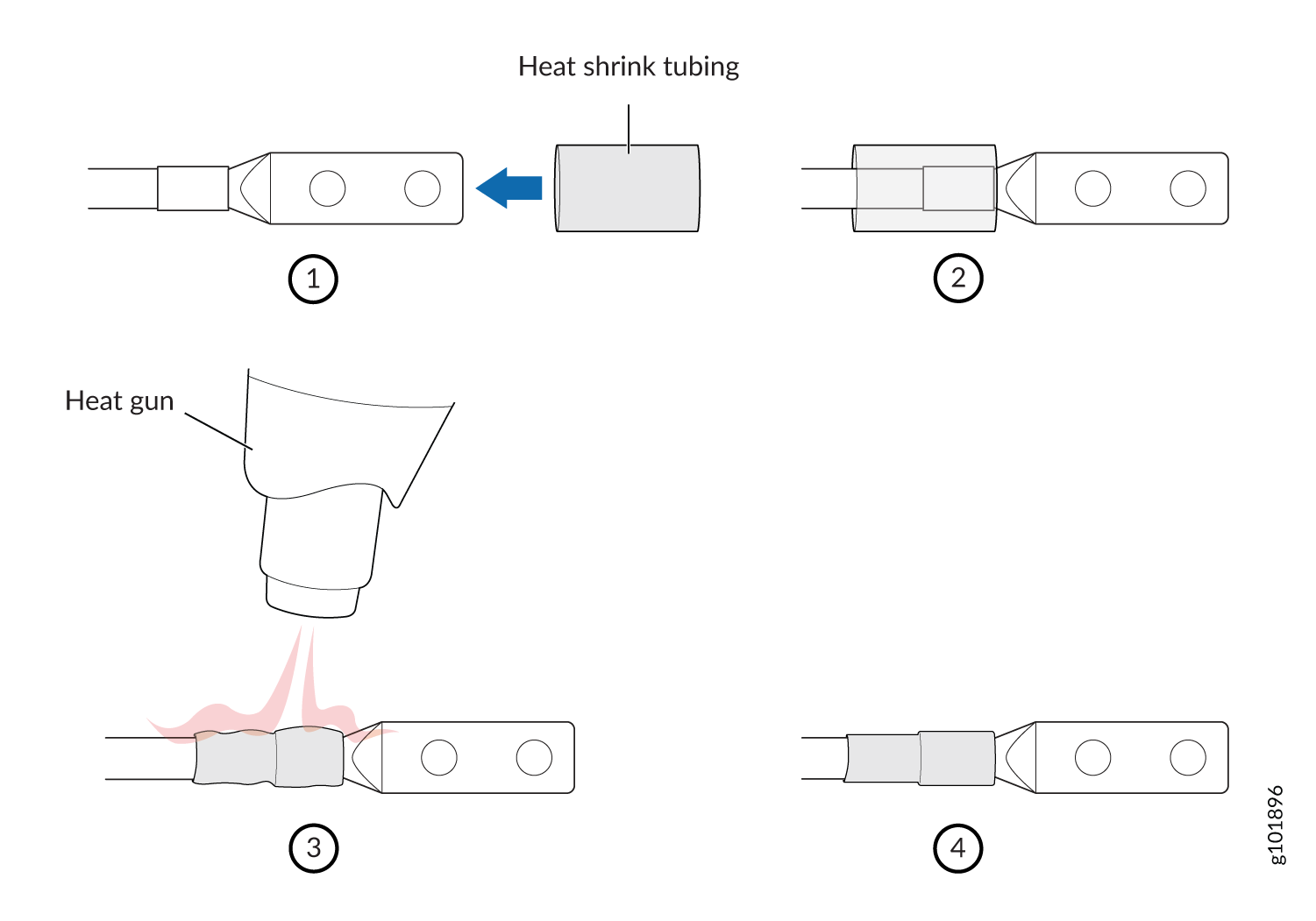

Before you connect power to the switch, a licensed electrician must attach a cable lug to the grounding and power cables that you supply. A cable with an incorrectly attached lug can damage the switch (for example, by causing a short circuit). To meet safety and electromagnetic interference (EMI) requirements and to ensure proper operation, you must connect the chassis to earth ground before you connect it to power. Under all circumstances, use the protective terminal on the switch chassis to connect to the earth ground.

The AC power supply unit (PSUs) in a QFX5230-64CD switch is a hot-removable and hot-insertable field-replaceable unit (FRU). You can remove and replace it without powering off the switch or disrupting routing functions.

To connect AC power to a QFX5230-64CD switch:

AC Circuit Breaker for the QFX5230-64CD Switch

- For Single / multiple feed AC power supply, we recommend that you use a dedicated 2-pole external circuit breaker for each power supply. Each feed of the power supply shall have a dedicated Line and Neutral connection.

- We recommend that the rating of the circuit breaker be a minimum of 125% of continuous current drawn by each power supply as per national electric or local code when system is fully configured.

- The model number of circuit breaker used for final safety certification is NF100-CN with current rating of 20A and with Medium Delay.

- The power supply of this system consists of an internal fuse with 20kA AIC rating.

- We recommend that you use appropriate rating of power cord and circuit breaker taking into consideration continuous current drawn when fully configured.

- See Table 1 to understand the electrical characteristics for the input fuse within the power supply.

|

Electrical Characteristics |

Value |

|---|---|

| Fuse | Littlefuse, 505 |

| Type of fuse (slow, fast) | Fast |

| Voltage rating | 500VAC |

| Current rating | 20A |

| AIC (interrupt rating) | 20kA |

| Approvals | UL, IEC |

| Melting integral | 210 |

|

Electrical Characteristics |

Value |

|---|---|

| Breaker | Shihlin Electric, NF100-CN |

| Delay (short, medium, long). | Medium |

| Type of Breaker | Magnetic |

| Voltage rating | 690V |

| Number of Poles | 2-pole |

| Current rating | 20A |

| AIC (interrupt rating) | 7.5kA |

| Approvals | UL, IEC |

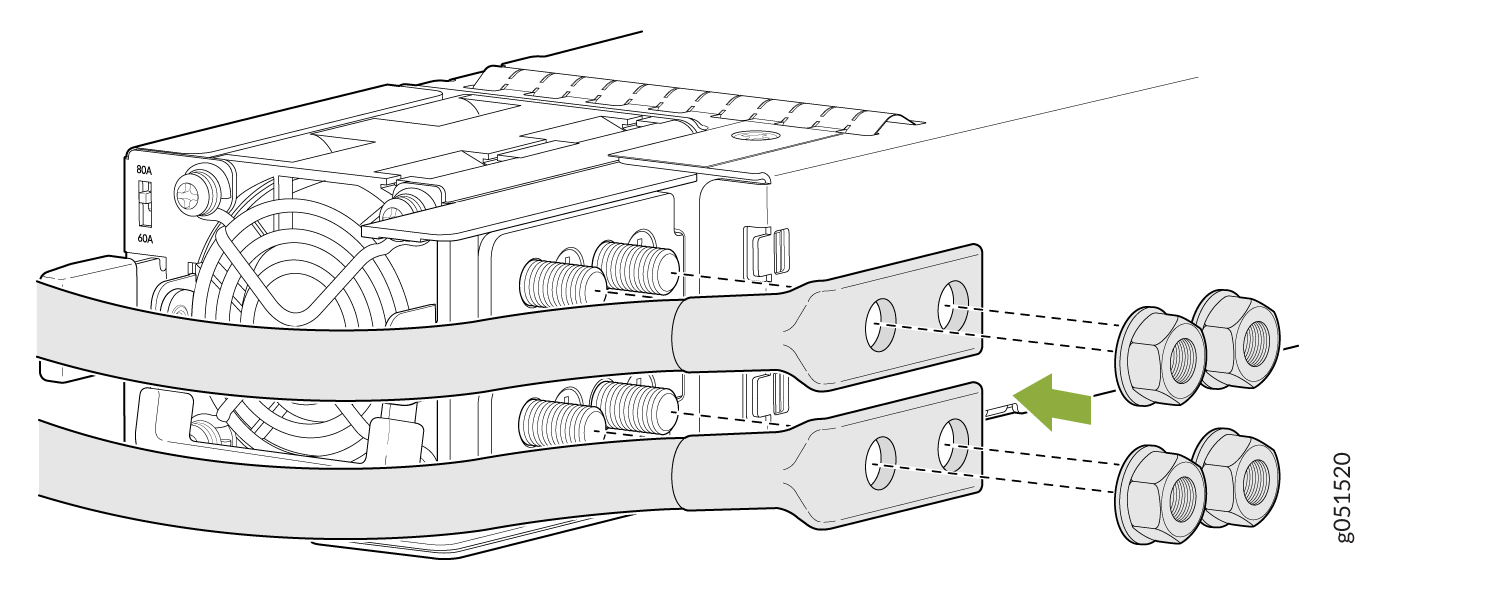

Connect DC Power to a QFX5230-64CD Switch

Before you connect power to the switch, a licensed electrician must attach a cable lug to the grounding and power cables that you supply. A cable with an incorrectly attached lug can damage the switch (for example, by causing a short circuit). To meet safety and electromagnetic interference (EMI) requirements and to ensure proper operation, you must connect the chassis to earth ground before you connect it to power. Under all circumstances, use the protective terminal on the switch chassis to connect to the earth ground.

-

Ensure that you have the following parts and tools available:

-

ESD grounding strap

-

Screwdriver

-

Nutdriver, with a torque range between 23 lb-in (2.6Nm) to 25 lb-in (2.8Nm)

CAUTION:You must use an appropriate torque-controlled tool to tighten the screws on the DC power cable connector. Do not overtighten the screws. Applying excessive torque damages the terminal block and the wiring tray. The absolute maximum torque that may be applied to this screw is 25 lb-in (2.8Nm).

- Two DC power source cables. The QFX5230-64CD switch supports a 4-AWG and 75°C temperature-rated stranded copper wire.

-

Do not mix AC and DC power supplies in the same chassis. Each power supply must be connected to a dedicated power source.

The DC power supply in a QFX5230-64CD switch is a hot-removable and hot-insertable field-replaceable unit (FRU). You can remove and replace it without powering off the switch or disrupting switch functions. You do, however, need to disconnect power supply before attempting to remove the unit.

The DC-powered QFX5230-64CD switch models are intended for installation in a restricted access location only.

To connect DC power to a QFX5230-64CD switch: