Connecting the PTX5000 to DC Power

Tools and Parts Required to Provide DC Power to the PTX5000

If you have a DC-powered router, gather the tools required to connect the PTX5000 to DC power:

7/16-in. (11-mm) nut driver, between 23 lb-in. to 25 lb-in. (2.6 Nm to 2.8 Nm) tightening torque, for tightening nuts to the terminal studs.

CAUTION:You must use an appropriate torque-controlled tool to tighten the nuts. Applying excessive torque damages the terminal studs. The maximum torque that may be applied to this nut is 62 lb-in. (7 Nm).

Phillips (+) screwdriver, number 2

DC power cables, which you must provide

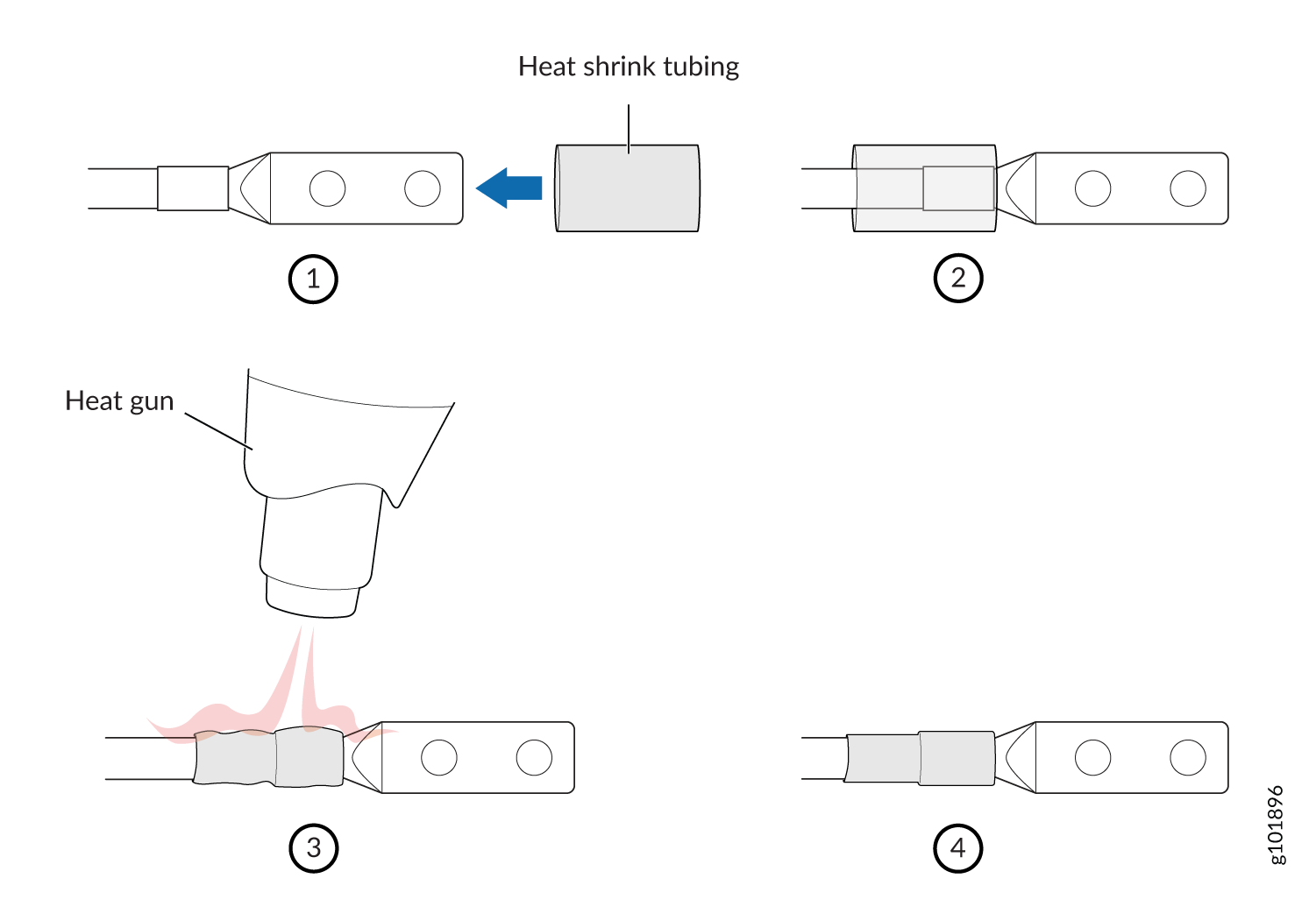

DC power lugs

Installing the PTX5000 Cable Management System for a High Capacity DC PDU

- Identifying the Parts of the Cable Management System

- Installing the Cable Management Comb Assembly with Extension

- Widening the Cable Management Comb Assembly Extension

- Installing the Cable Management Comb Assembly Without Extension

Identifying the Parts of the Cable Management System

You cannot install this cable management system on a two-post rack.

1 — Comb assembly | 3 — Extension panel—Outside piece |

2 — Extension panel—Inside piece |

Installing the Cable Management Comb Assembly with Extension

Ensure that while mounting the PTX5000 chassis on the four-post rack, you leave at least 1.75 in. (4.45 cm) between the bottom of the PTX5000 chassis and the floor, so that there is enough space to install the High Capacity DC power system and to connect the cables.

To install the comb assembly to the rack:

Widening the Cable Management Comb Assembly Extension

The cable manager comb assembly extension is fixed at the minimum (default) position when shipped. You can widen the comb assembly, if the rear edge of the PTX5000 chassis extends out from the rack post and you do not have enough space to route the cables with the default comb assembly extension width.

To widen the comb assembly extension:

Installing the Cable Management Comb Assembly Without Extension

You can use only the comb assembly without the extension, if the rear edge of the PTX5000 chassis is aligned with the four-post rack. In such a scenario, only the comb assembly is sufficient to route the cables.

To install the comb assembly on the four-post rack:

Connecting Power to the PTX5000 60-A DC Input Power Trays

To connect the DC source power cables to the 60-A DC inputs:

Connecting Power to the PTX5000 120-A DC Input Power Trays

To connect the DC source power cables to the 120-A DC inputs:

Connecting Power to the PTX5000 High Capacity DC PDUs

To connect the DC source power cables to the High Capacity DC inputs: